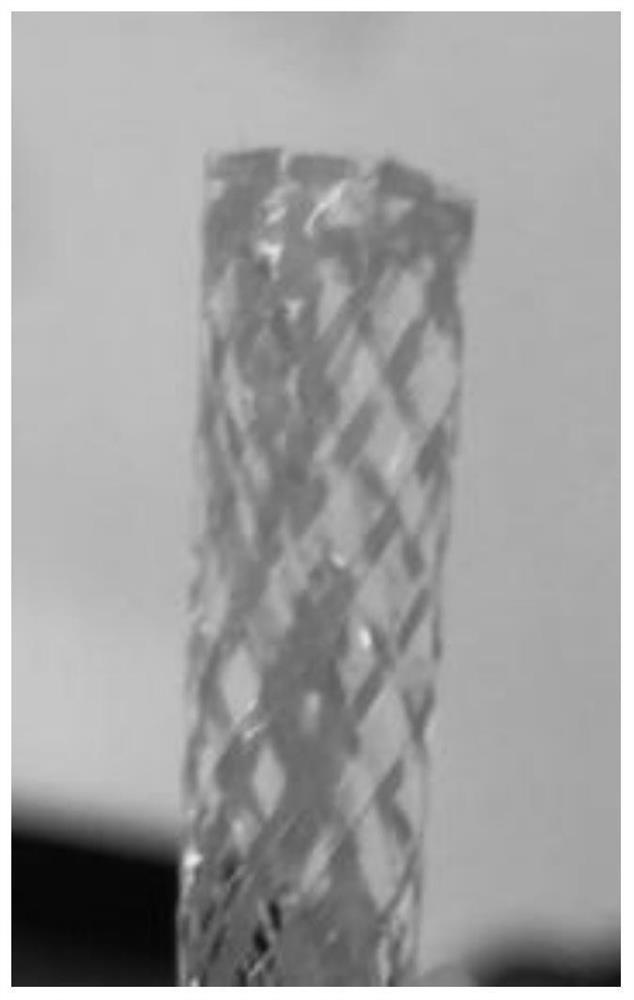

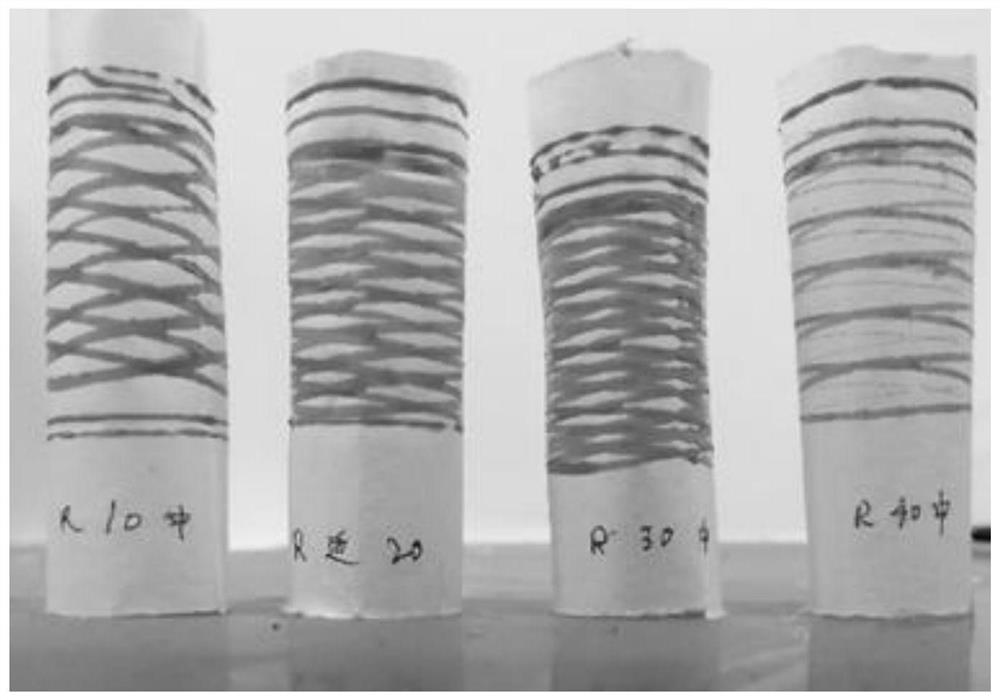

Preparation method of tanshinone Ⅱa vascular stent based on 3D printing

A vascular stent and 3D printing technology, applied in the field of medical device preparation, can solve the problems of vascular wall damage, excessive drug release, secondary stimulation of the body, etc., to reduce vascular restenosis, improve quality of life, and drug load. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Each medicine that adopts among the present invention is:

[0025] Tanshinone IIA API (Xi'an Hao'an Company, 98%, batch number: HXDST2A140110);

[0026] Polylactic acid PLA (300KD, Dongguan Zhanyang Polymer Material Co., Ltd.);

[0027] Ethanol (analytical grade, Kunshan Jincheng Reagent Co., Ltd., batch number: 20190618);

[0028] Dichloromethane (analytical pure, Shanghai Shisi Hewei Chemical Co., Ltd.);

[0029] Each instrument that adopts in the present invention is:

[0030] Electronic balance (FA2004B, Shanghai Youke Instrument Co., Ltd.);

[0031] JN-3200D ultrasonic cleaning machine (Ningbo Jiangnan Instrument Factory);

[0032] JJ-1 precision electric stirrer (Hongke Instrument Factory, Jintan City, Jiangsu Province);

[0033] 3D printers and 3D printing software in the prior art;

[0034] RC membrane dialysis bag (Mw=8000-14000, MD34, Beijing solarbio Co., Ltd.);

[0035] UV-5800PC ultraviolet spectrophotometer (Shanghai Yuan Analysis Instrument Co., Lt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com