Micro light-emitting diode epitaxial structure and preparation method thereof

An epitaxial structure, light-emitting area technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of unstable photoelectric conversion efficiency, decreased photoelectric conversion efficiency, low current density that cannot be applied to epitaxial wafers, etc. It can improve the radiative recombination efficiency and photoelectric conversion efficiency of carriers, reduce the defect density, and improve the carrier transport and recombination behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

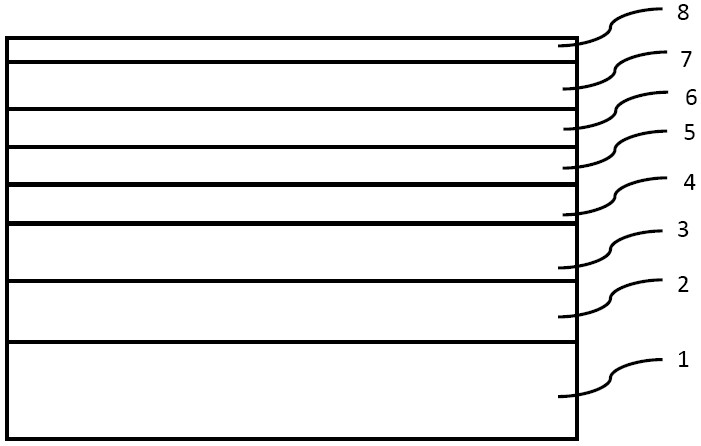

[0056] Please refer to Figure 1~Figure 5 , based on the purpose of the present invention, this embodiment provides a micro-LED epitaxial structure and a manufacturing method thereof, including the following process steps:

[0057] (1) Provide a substrate 1, which can be sapphire (Al 2 o 3 ), AlN or SiNx-plated sapphire (Al 2 o 3 ), Ga 2 o 3 , AlN or SiNxGa plating 2 o 3 , SiC, GaN, ZnO, Si or Ge at least one, this embodiment is preferably coated with AlN sapphire substrate.

[0058] (2) Epitaxial growth of the nucleation layer on the substrate 1 (not shown in the figure): AlGaN material is preferred, and the epitaxial growth method can be MOCVD (metal organic chemical vapor deposition) method, MBE (molecular beam epitaxy) method, CVD ( Chemical Vapor Deposition) method, HVPE (Hydride Vapor Phase Epitaxy) method, PECVD (Plasma Enhanced Chemical Vapor Deposition) method, preferably MOCVD, but the embodiment is not limited thereto. Put the AlN-coated sapphire substrate ...

Embodiment 2

[0069] In this embodiment, an alternative implementation is provided, which is specifically provided as follows.

[0070] The description of the light-emitting area is as follows: the difference from the first embodiment is as follows, this embodiment is a multi-well layer design, as follows:

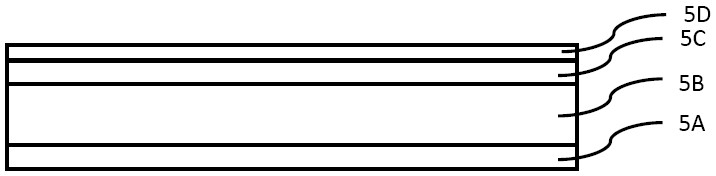

[0071] The first luminous area: can refer to Image 6 . After the growth of the third barrier layer 5C is completed, the first well layer 52D begins to grow during the process of cooling down to the temperature of the well layer (700~800°C), and the TMIN 1000sccm is injected, the material is InGaN, the rate is about 0.6 Å / s, and the thickness About 3~8 angstroms. After the growth of the first well layer is completed, the second well layer 52E is grown, the material is InGaN, the rate is about 0.3 angstroms / s, and the thickness is about 5~15 angstroms. After the growth of the second well layer is completed, When the temperature is raised to the barrier layer temperature (800-900° C.), ...

Embodiment 3

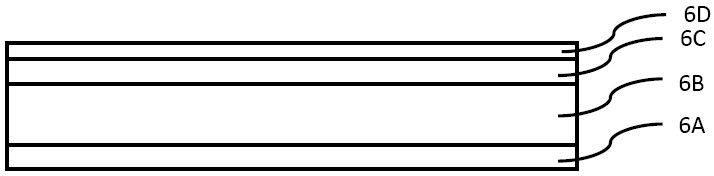

[0076] In this embodiment, an alternative implementation is provided, which is specifically provided as follows. The difference from the first embodiment is that the composite light emitting area is a combination of the first light emitting area and the second light emitting area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com