Natural antibacterial mask base cloth, preparation method thereof and mask

A mask and base fabric technology, applied in non-woven fabrics, pharmaceutical formulations, rayon manufacturing, etc., can solve the problems of skin irritation, small adsorption capacity, mask deterioration, etc., to achieve enhanced mechanical properties, good liquid retention performance, and improved The effect of liquid retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

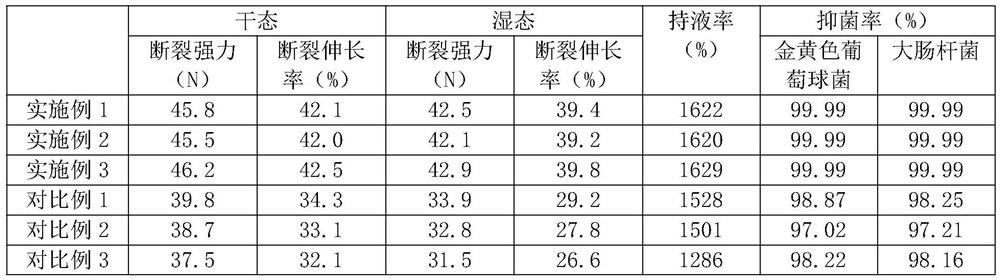

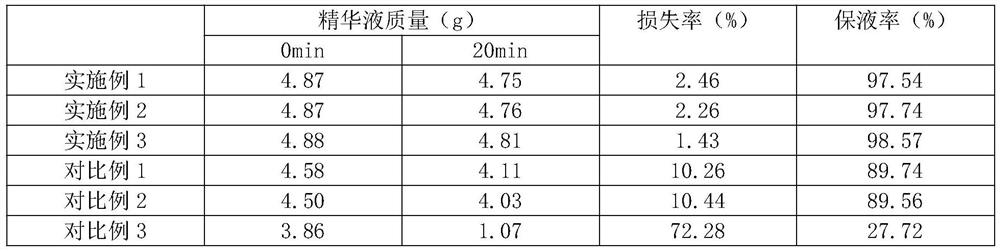

Examples

Embodiment 1

[0031] A kind of preparation method of natural antibacterial mask base cloth, concrete steps are as follows:

[0032] (1) Raspberry is used as raw material first, and it is subjected to supercritical CO 2 Fluid extraction to obtain raspberry extract, then mix it with deacetylated konjac glucomannan to make a spinning solution, and electrospin to obtain fiber I;

[0033] (2) Then, the fullerene is modified with silk fibroin to obtain an intermediate product, which is then mixed with lactic acid and polymerized to obtain modified fullerene, which is melt-spun to obtain fiber II;

[0034] (3) Finally, fiber I and fiber II are mixed to form a spunlace non-woven fabric, and the mask base fabric is obtained.

[0035] In step (1), supercritical CO 2 The process conditions of fluid extraction are: extraction pressure 9MPa, extraction temperature 55°C, CO 2 The flow rate is 20L / h, and the extraction time is 3 hours.

[0036] In step (1), supercritical CO 2 The product obtained by ...

Embodiment 2

[0047] A kind of preparation method of natural antibacterial mask base cloth, concrete steps are as follows:

[0048] (1) Raspberry is used as raw material first, and it is subjected to supercritical CO 2 Fluid extraction to obtain raspberry extract, then mix it with deacetylated konjac glucomannan to make a spinning solution, and electrospin to obtain fiber I;

[0049] (2) Then, the fullerene is modified with silk fibroin to obtain an intermediate product, which is then mixed with lactic acid and polymerized to obtain modified fullerene, which is melt-spun to obtain fiber II;

[0050] (3) Finally, fiber I and fiber II are mixed to form a spunlace non-woven fabric, and the mask base fabric is obtained.

[0051] In step (1), supercritical CO 2 The process conditions of fluid extraction are: extraction pressure 10MPa, extraction temperature 45°C, CO 2 The flow rate is 23L / h, and the extraction time is 2 hours.

[0052] In step (1), supercritical CO 2 The product obtained by...

Embodiment 3

[0063] A kind of preparation method of natural antibacterial mask base cloth, concrete steps are as follows:

[0064] (1) Raspberry is used as raw material first, and it is subjected to supercritical CO 2 Fluid extraction to obtain raspberry extract, then mix it with deacetylated konjac glucomannan to make a spinning solution, and electrospin to obtain fiber I;

[0065] (2) Then, the fullerene is modified with silk fibroin to obtain an intermediate product, which is then mixed with lactic acid and polymerized to obtain modified fullerene, which is melt-spun to obtain fiber II;

[0066] (3) Finally, fiber I and fiber II are mixed to form a spunlace non-woven fabric, and the mask base fabric is obtained.

[0067] In step (1), supercritical CO 2 The process conditions of fluid extraction are: extraction pressure 10MPa, extraction temperature 50°C, CO 2 The flow rate is 22L / h, and the extraction time is 2.5 hours.

[0068] In step (1), supercritical CO 2 The product obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com