A preparation method of temperature-sensitive flow pattern regulator for deepwater water-based drilling fluid

A flow regulator, deep-water water-based technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature response, low-temperature viscosity increase, poor temperature resistance, etc., and achieve hydrophobic association Strong effect, improved high temperature resistance, strong hydrophobic association effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

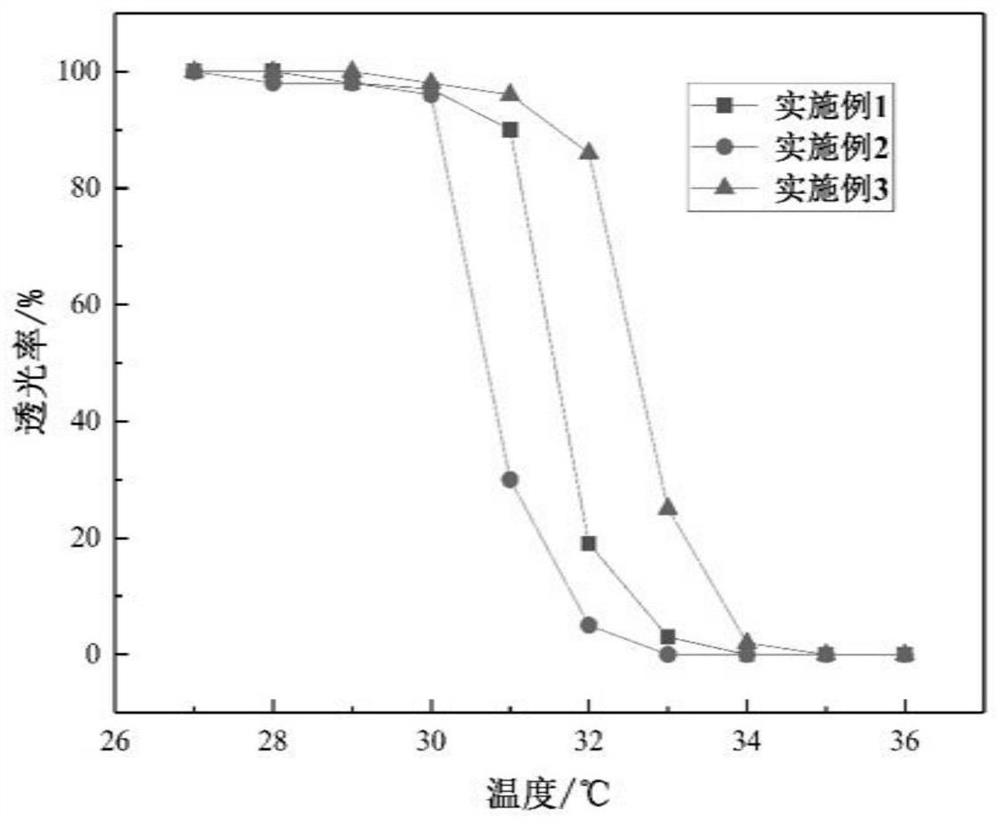

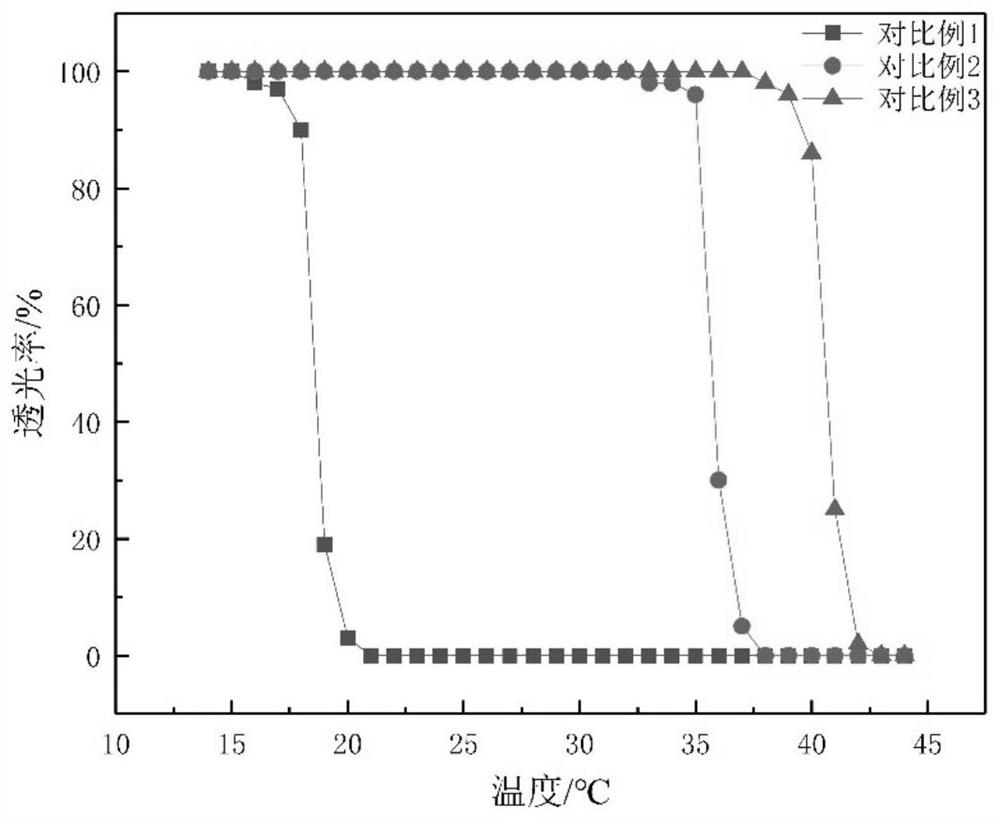

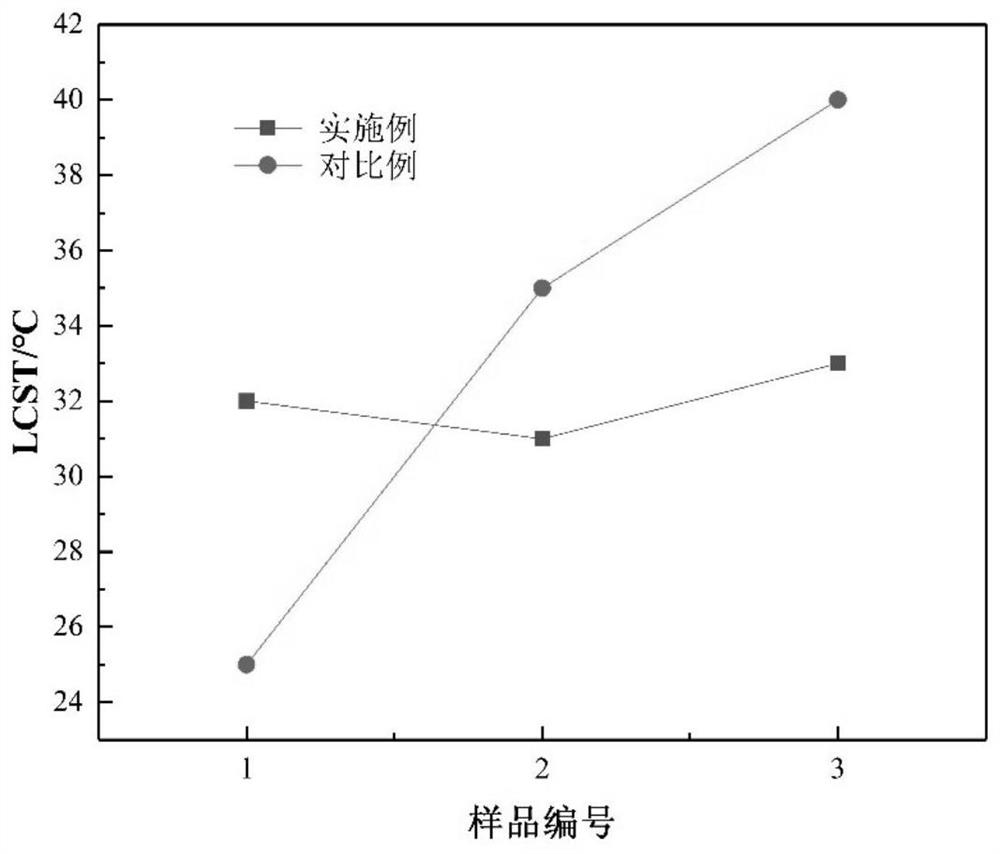

Embodiment 1

[0045] A method for preparing a temperature-sensitive flow pattern regulator for deepwater water-based drilling fluids, comprising the following steps:

[0046] (1) Add 20 g of N-isopropylacrylamide, 4 g of acrylic acid, 2 g of caprolactam, and 2 g of acrylamide into 200 mL of deionized water, mix well, and then use a sodium hydroxide solution with a mass concentration of 30 wt % to adjust the pH of the system to 7.0, to obtain a mixture.

[0047] (2) Add 5 g of butyl acrylate, 5 g of lauryl acrylate, 8 g of 2-acrylamido-2-methylpropanesulfonic acid, and 2 g of emulsifier MS-1 to the mixed solution obtained in step (1), mix well, and use Shear emulsification machine emulsification, rotation speed 3000r / min, emulsification time 20min, to obtain the pre-emulsion.

[0048] (3) Place the pre-emulsion obtained in step (2) in a three-necked flask, heat it to 60°C, add 4 mL of 0.05 g / mL potassium persulfate aqueous solution dropwise under stirring, and add 8 mL of 0.05 g / mL potassiu...

Embodiment 2

[0050] A method for preparing a temperature-sensitive flow pattern regulator for deepwater water-based drilling fluids, comprising the following steps:

[0051] (1) Add 20g of N-vinylpyrrolidone, 4g of methacrylic acid, 2g of caprolactam, 1g of acrylamide, and 1g of N-methylolacrylamide into 200mL of deionized water, mix well, and then oxidize The sodium solution adjusted the pH of the system to 7.0 to obtain a mixed solution.

[0052] (2) Add 5g of lauryl acrylate, 5g of stearyl acrylate, 8g of styrene, and 2g of emulsifier MS-1 to the mixed solution obtained in step (1), mix well, and emulsify with a shear emulsifier at a speed of 3000r / min , and the emulsification time was 20min to obtain a pre-emulsion.

[0053] (3) Place the pre-emulsion obtained in step (2) in a three-necked flask, heat it to 60°C, add 4 mL of 0.05 g / mL potassium persulfate aqueous solution dropwise under stirring, and add 8 mL of 0.05 g / mL potassium persulfate solution dropwise after stirring for 10 mi...

Embodiment 3

[0055] A method for preparing a temperature-sensitive flow pattern regulator for deepwater water-based drilling fluids, comprising the following steps:

[0056] (1) Add 10g of N-isopropylacrylamide, 10g of N-vinylcaprolactam, 2g of acrylic acid, 2g of methacrylic acid, and 4g of N-methylolacrylamide into 200mL of deionized water, mix well, and then use a mass concentration of The pH of the system was adjusted to 7.0 with 30 wt% sodium hydroxide solution to obtain a mixed solution.

[0057] (2) Add 6 g of octadecyl acrylate, 4 g of methyl methacrylate, 4 g of sodium styrene sulfonate, 4 g of sodium 4-hydroxybenzene sulfonate, 2 g of emulsifier MS-1 into the mixed solution obtained in step (1), and mix Evenly, use a shear emulsifier to emulsify with a rotation speed of 3000r / min and an emulsification time of 20min to obtain a pre-emulsion.

[0058] (3) Place the pre-emulsion obtained in step (2) in a three-necked flask, heat it to 60°C, add 4 mL of 0.05 g / mL potassium persulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com