Composite graphene-based wind power bearing lubricating oil and preparation method thereof

A technology of composite graphene and lubricating oil, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of anti-wear and poor lubricating performance of lubricating oil, achieve excellent anti-wear effect, good self-sealing effect, and prevent high temperature oil leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

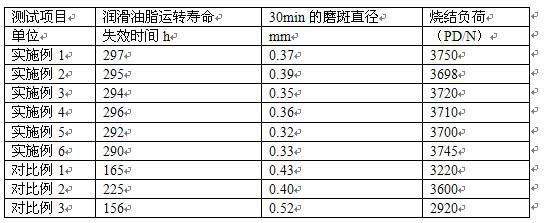

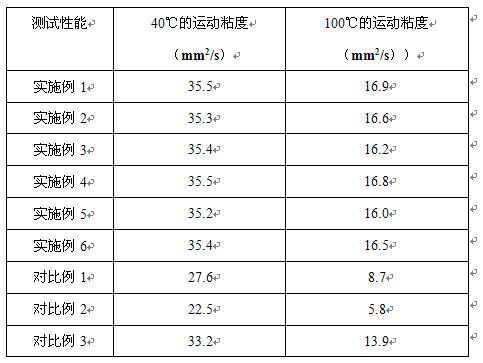

Examples

Embodiment 1

[0031] A kind of composite graphene base wind power bearing lubricating oil, described composite graphene base wind power bearing lubricating oil comprises the raw material of following parts by weight:

[0032] 78 parts of base oil, 10 parts of thickener, 2.5 parts of graphene-silica gel compound, 0.6 part of polyisobutylene dioic acid pentapentylmethyl ester, 0.4 part of zinc dialkyldithiophosphate, dithiocarbamate 0.8 parts, 0.4 parts of copper salt calcium sulfonate, 0.3 parts of antioxidant, 1.5 parts of tungsten-molybdenum alloy powder. Wherein, the base oil is polyalpha-olefin; the thickener is 12 hydroxy lithium stearate soap; the thickener is 12 hydroxy lithium stearate soap; the antioxidant is bisphenol antioxidant agent;

[0033] The graphene-silica gel composite is prepared by the following method: disperse graphene in an aqueous solution of water glass, add dilute sulfuric acid and stir evenly, then let stand, wash with water, dry, and grind to obtain a graphene-...

Embodiment 2

[0040] A kind of composite graphene base wind power bearing lubricating oil, described composite graphene base wind power bearing lubricating oil comprises the raw material of following parts by weight: base oil 75 parts, thickening agent 8 parts, graphene-silica gel compound 2 parts, poly 0.5 part of quaternylmethyl isobutylene dioate, 0.3 part of zinc dialkyldithiophosphate, 0.5 part of dithiocarbamate, 0.3 part of copper salt calcium sulfonate, 0.2 part of antioxidant, tungsten-molybdenum alloy powder 1 serving. Wherein, the base oil is polyalpha-olefin; the thickener is hydrogenated castor oil lithium soap; the thickener is 12 hydroxy lithium stearate soap; the antioxidant is a bisphenol antioxidant;

[0041] The graphene-silica gel composite is prepared by the following method: disperse graphene in an aqueous solution of water glass, add dilute sulfuric acid and stir evenly, then let stand, wash with water, dry, and grind to obtain a graphene-silica gel composite; The aq...

Embodiment 3

[0048] A kind of composite graphene base wind power bearing lubricating oil, described composite graphene base wind power bearing lubricating oil comprises the raw material of following parts by weight: base oil 80 parts, thickening agent 12 parts, graphene-silica gel compound 3 parts, poly 0.8 part of quaternyl methyl isobutylene dioate, 0.4 part of zinc dialkyldithiophosphate, 0.8 part of dithiocarbamate, 0.4 part of copper salt calcium sulfonate, 0.4 part of antioxidant, tungsten-molybdenum alloy powder 2 servings. Wherein, the base oil is polyalpha-olefin; the thickener is lithium stearate soap; the thickener is 12 hydroxy lithium stearate soap; the antioxidant is a bisphenol antioxidant;

[0049] The graphene-silica gel composite is prepared by the following method: disperse graphene in an aqueous solution of water glass, add dilute sulfuric acid and stir evenly, then let stand, wash with water, dry, and grind to obtain a graphene-silica gel composite; The aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com