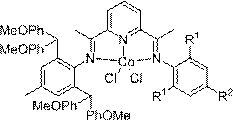

Pyridinimine cobalt complex containing diphenylmethoxy group and its preparation method and application

A technology of diphenylmethoxyl and cobalt pyridinium, applied in the field of cobalt pyridinium complexes and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

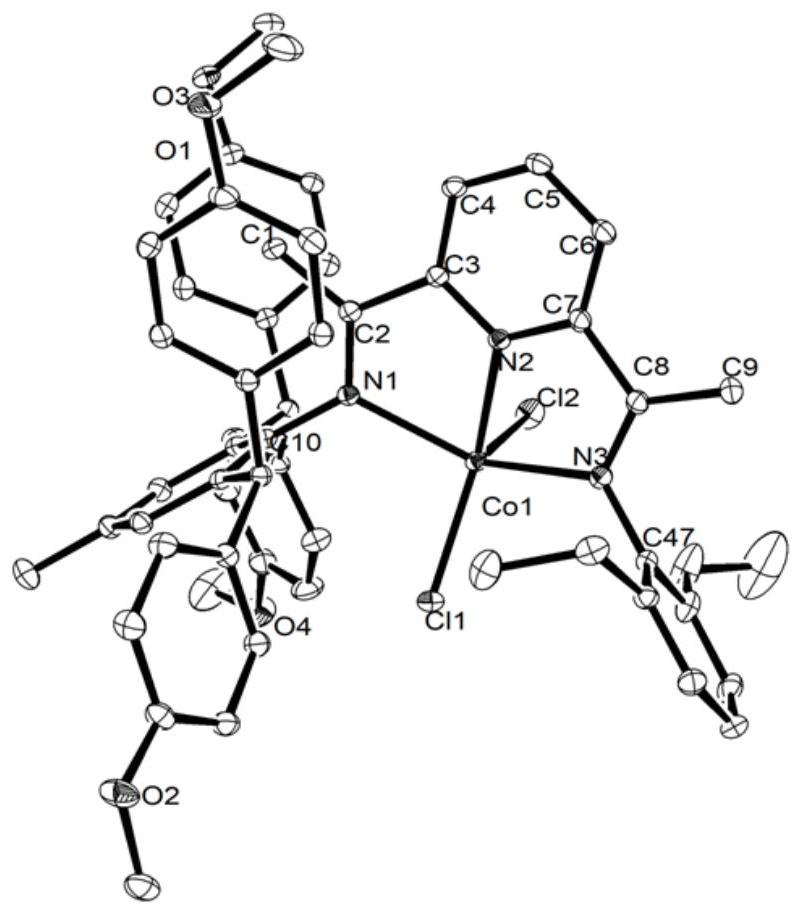

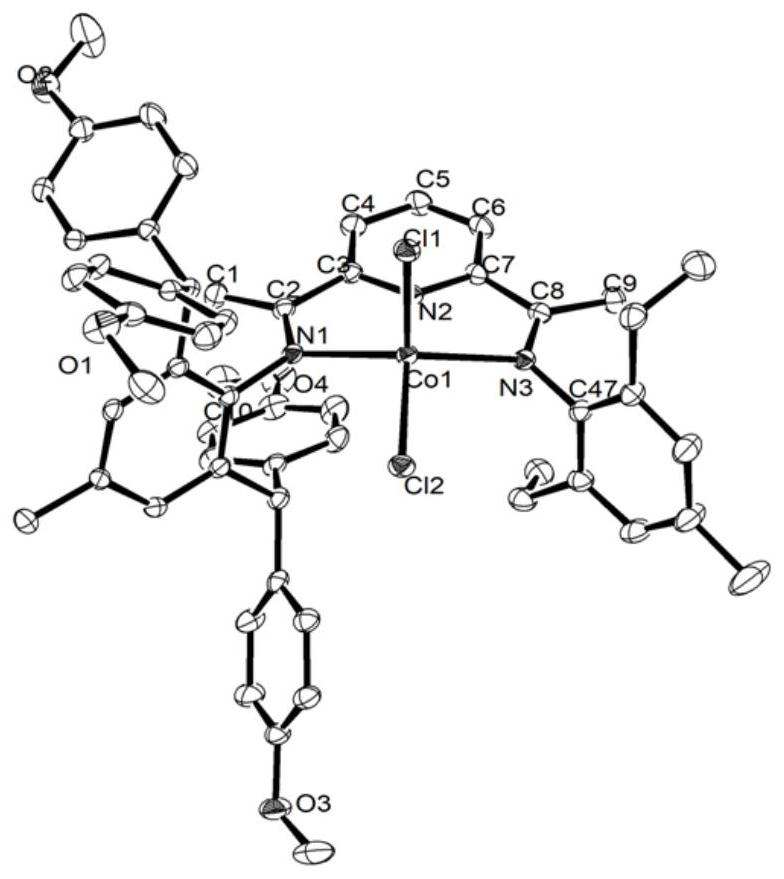

Image

Examples

Embodiment 1

[0019] (1) Preparation of ligand

[0020] A catalytic amount of p-toluenesulfonic acid was added in batches to 2,6-diacetylpyridine (23.0 mmol) and 2,6-bis(4,4′-dimethoxybenzhydryl)-6 - Methylaniline (20.0mmol) in toluene mixture, heated to 120°C, continued to reflux for 9 hours, concentrated the solution, using petroleum ether / ethyl acetate (v / v=20:1) as eluent, column The reaction product was purified by chromatography to obtain the intermediate product M.

[0021] Add the intermediate product M (2mmol) in batches to the toluene solution of 2,4,6-trimethylaniline (2.5mmol), add an appropriate amount of p-toluenesulfonic acid in batches under stirring, heat to 120°C, and reflux After 15 hours, after the reaction was complete, concentrate, use petroleum ether / ethyl acetate (v / v=100:3) as the eluent, purify by column chromatography, wash, suction filter, and crystallize to obtain diphenylmethoxyl-containing Pyridine imine ligand compound L1;

[0022] L2(R 1 =Et,R 2 =H), L3...

Embodiment 2

[0038] Polymerization of ethylene under pressure using complex C1 and MAO cocatalyst:

[0039] Under an ethylene environment, 25 mL of toluene, 25 mL of toluene solution of catalyst C1 (1.5 μmol), 2.6 mL of cocatalyst MAO (1.46 mol / L toluene solution), and 50 mL of toluene were sequentially added to a 250 mL stainless steel autoclave. At this time, Al / Co=2500:1. Start the mechanical stirring and keep it at 400 rpm. When the polymerization temperature reaches 60°C, fill the reactor with ethylene, and the polymerization reaction starts. Maintain an ethylene pressure of 10 atm at 60°C and stir for 30 min. The reaction was quenched with 5% hydrochloric acid and ethanol solution to obtain a polymer precipitate, which was washed several times with ethanol, dried in vacuum until constant weight, and weighed.

[0040] Polymerization activity: 8.71×10 6 g·mol -1 (Co)·h -1 , Polymer T m = 117.1°C. (T m For the melting temperature of polymer, obtained by DSC test), polymer molecu...

Embodiment 3

[0042] Polymerization of ethylene under pressure using complex C2 and MAO cocatalyst:

[0043] Under an ethylene environment, 25 mL of toluene, 25 mL of toluene solution of catalyst C1 (1.5 μmol), 2.6 mL of cocatalyst MAO (1.46 mol / L toluene solution), and 50 mL of toluene were sequentially added to a 250 mL stainless steel autoclave. At this time, Al / Co=2500:1. Start the mechanical stirring and keep it at 400 rpm. When the polymerization temperature reaches 60°C, fill the reactor with ethylene, and the polymerization reaction starts. Maintain an ethylene pressure of 10 atm at 60°C and stir for 30 min. The reaction was quenched with 5% hydrochloric acid and ethanol solution to obtain a polymer precipitate, which was washed several times with ethanol, dried in vacuum until constant weight, and weighed. Polymerization activity: 6.37×10 6 g·mol -1 (Co)·h -1 , Polymer T m =117.5°C, M w =3.38×10 5 g·mol -1 , PDI=1.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com