Acid-resistant glass fiber composition, acid-resistant glass fiber and preparation method of acid-resistant glass fiber

A glass fiber and acid-resistant technology, applied in the field of acid-resistant glass fiber and its preparation, and acid-resistant glass fiber composition, can solve the problems of poor physical properties such as tensile strength, inability to be used as electrical insulating materials, and high alkali content. Achieve the effects of improving mechanical properties and corrosion resistance, reducing the difficulty of molding operations, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing glass fibers, comprising: preparing raw materials according to the above-mentioned glass fiber composition; melting the raw materials to obtain molten glass; drawing the molten glass to obtain glass fibers.

[0043] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0044] Prepare raw materials according to the above-mentioned glass fiber composition; in the present invention, the above-mentioned glass fiber composition is preferably derived from pyrophyllite, quartz sand, calcite, potassium feldspar, sodium oxide, calcium oxide, zircon, boronite and soda ash, and is prepared raw material.

[0045] The raw materials are melted to obtain molten glass; in the present invention, the melting is preferably carried out in a kiln; the raw materials are preferably transported to the kiln by conveying equipment; the conveying equipment i...

Embodiment 1

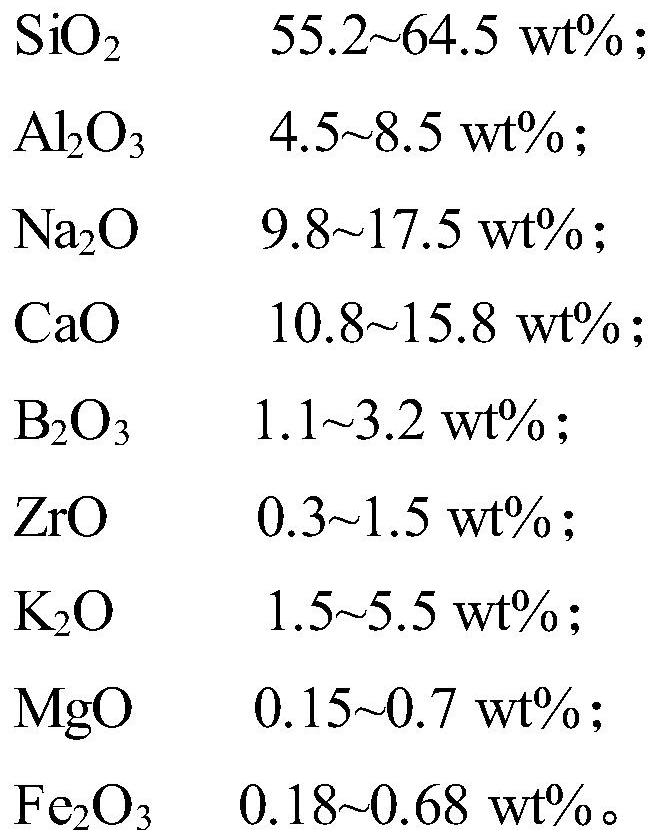

[0051] A kind of acid-resistant glass fiber composition, its main component and its weight content are:

[0052] SiO 2 : 55.2%, Al 2 o 3 : 8.5%, Na 2 O: 12.8%, CaO: 14.8%, K 2 O: 5.5%, B 2 o 3 : 1.5%, ZrO: 0.32%, MgO: 0.70%, Fe 2 o 3 : 0.68%.

[0053] The preparation method of glass fiber is as follows:

[0054] According to the chemical composition of the formulas listed above, the proportioning requirements of various raw materials are obtained through detection and calculation. , Soda ash is used as the raw material, and after being accurately measured by the weighing system, it is evenly mixed by the mixing system to make batch materials. The batch materials are transported to the front warehouse of the kiln through a pneumatic conveying system, fed by an automatic feeder, and melted at 1510°C in a kiln fired with pure oxygen to obtain clarified and homogenized molten glass. The melted glass flows to the wire drawing channel and the wire drawing forming system t...

Embodiment 2

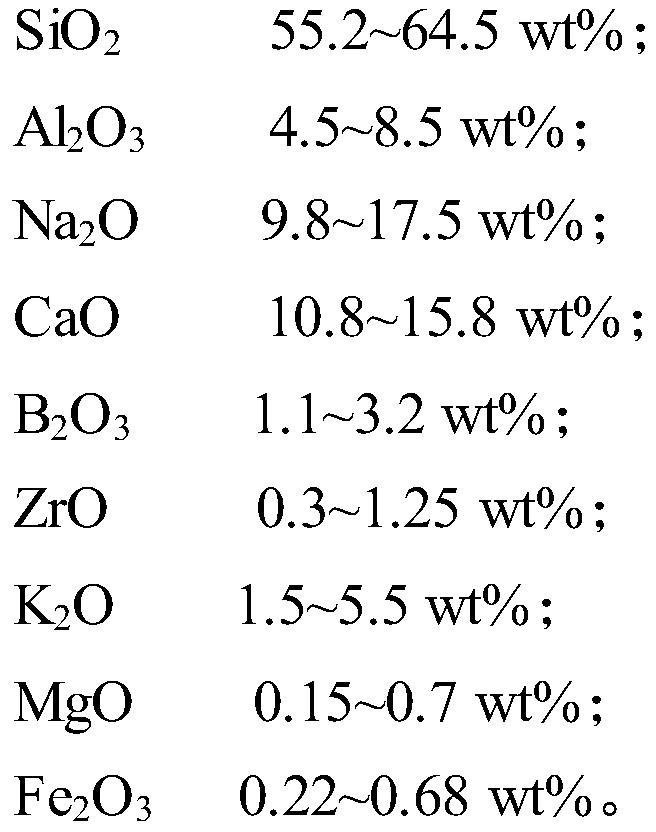

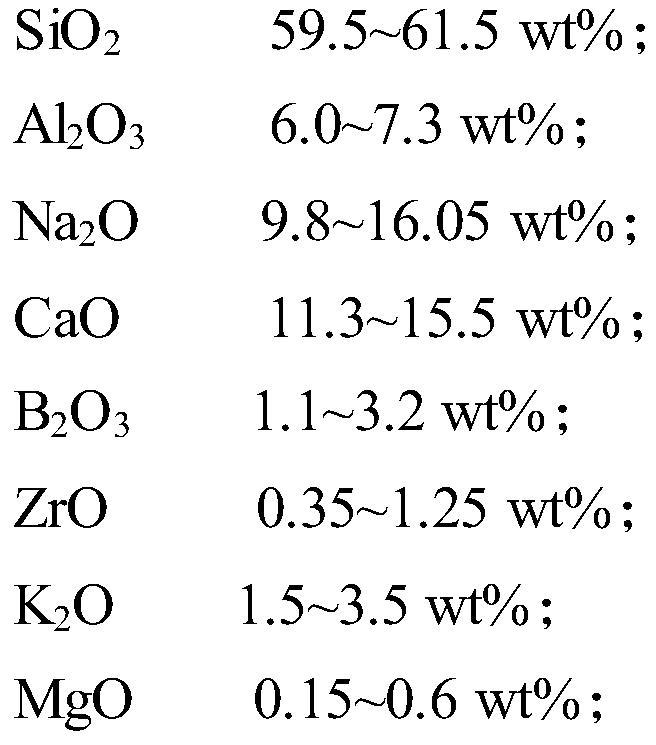

[0056] A kind of glass fiber composition, its main component and its weight content are:

[0057] SiO 2 : 64.5%, Al 2 o 3 : 5.5%, Na 2 O: 13.0%, CaO: 11.3%, K 2 O: 3.0%, B 2 o 3 : 1.3%, ZrO: 0.50%, MgO: 0.52%, Fe 2 o 3 : 0.38%.

[0058] The preparation method of glass fiber is as follows:

[0059] According to the chemical composition of the formulas listed above, the proportioning requirements of various raw materials are obtained through detection and calculation. , Soda ash is used as the raw material, and after being accurately measured by the weighing system, it is evenly mixed by the mixing system to make batch materials. The batch materials are transported to the front warehouse of the kiln through a pneumatic conveying system, fed by an automatic feeder, and smelted at 1450°C by a kiln with pure oxygen combustion and electric assistance to obtain clarified and homogenized molten glass. The melted glass flows to the wire drawing channel and the wire drawing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com