Cold diffusion remediation rod based on organic contaminated soil

A technology of organic pollution and soil remediation agent, applied in the field of cold diffusion repair rods, can solve problems such as unrealistic, troublesome, and reduced soil remediation efficiency, and achieve the effect of improving absorption efficiency and promoting shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

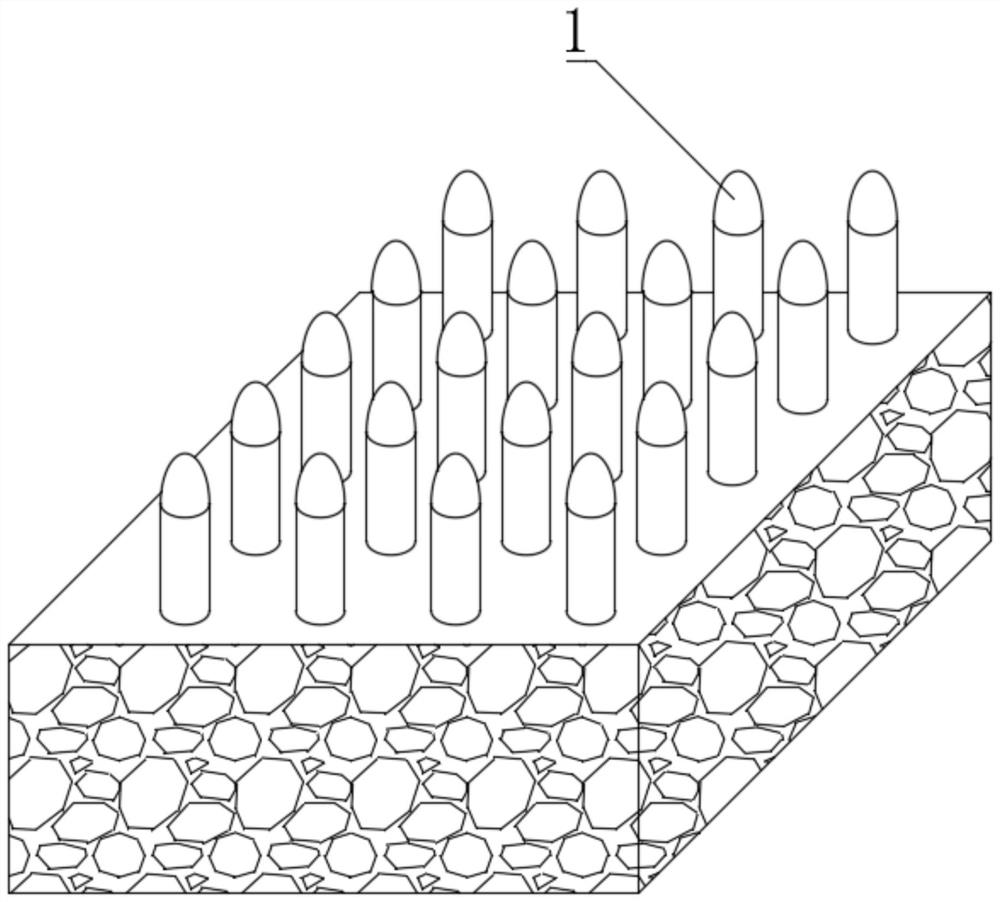

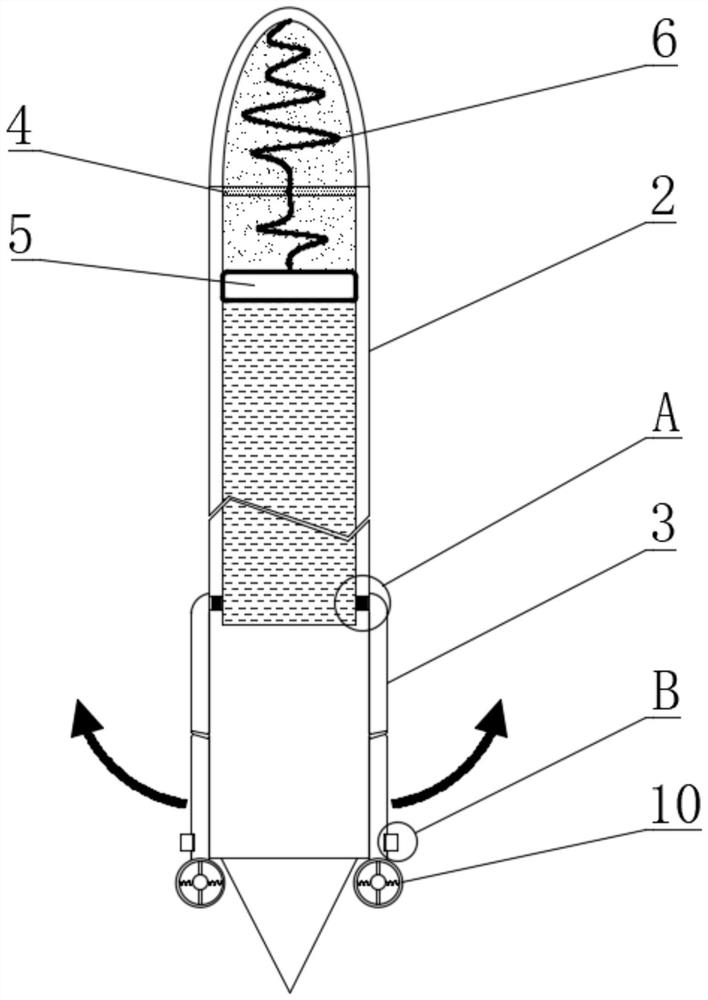

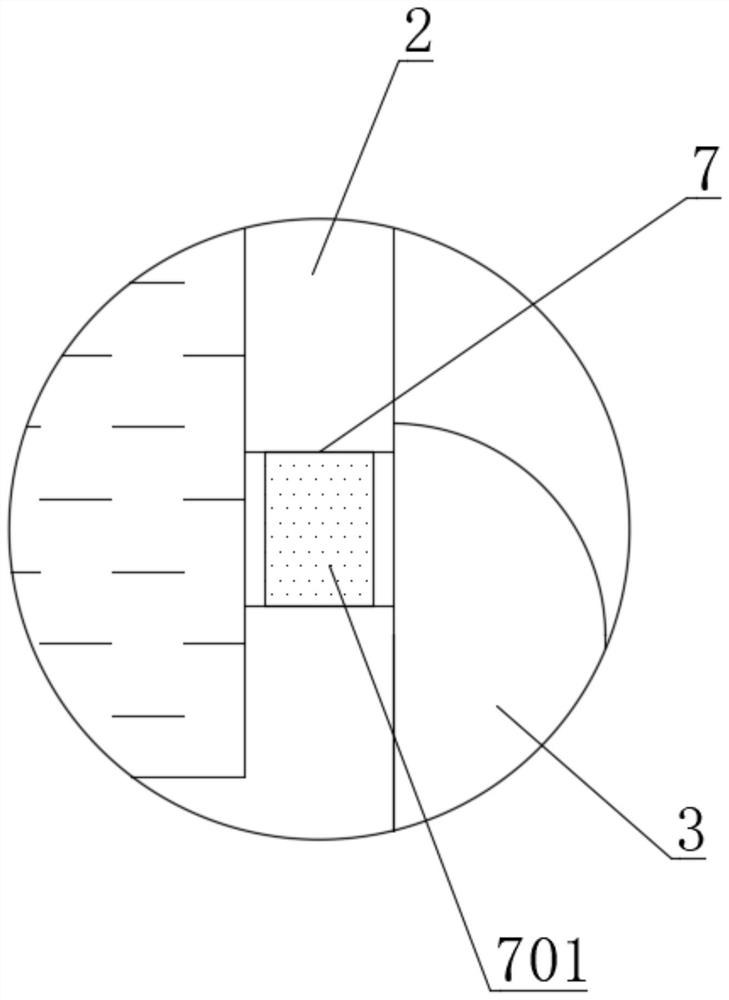

[0047] see Figure 1-5 , a cold diffusion repair rod based on organic polluted soil, comprising a plurality of pre-embedded repair rods 1 evenly inserted in the soil, the pre-embedded repair rod 1 includes a repair storage cylinder 2, and the outer end of the repair storage cylinder 2 is fixedly connected with multiple Uniformly distributed lateral diffusion hose 3, the inner wall of the repair storage cylinder 2 is fixedly connected with a closed round paper piece 4, and the inner wall of the repair storage cylinder 2 is slidably connected with a movable plug plate 5, between the movable plug plate 5 and the inner top of the repair storage cylinder 2 A metal connecting rope 6 that runs through the closed round paper sheet 4 is fixedly connected, and the inner wall of the repair storage cylinder 2 is dug with a plurality of first diversion guide holes 7 that are evenly distributed and communicated with the lateral diffusion hose 3 , and the lateral diffusion hose 3 The inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com