Thermoplastic elastomer composition and production method therefor

A thermoplastic elastomer and a manufacturing method technology, applied in the field of thermoplastic elastomer compositions, can solve the problems of excellent moldability, heterogeneous mixture, insufficient rubber elasticity, etc., and achieve the effects of excellent ozone resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0193] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited to these examples.

[0194]

[0195] In the following examples and comparative examples, each property was measured or evaluated as follows.

[0196] Number average molecular weight (Mn)

[0197] The number average molecular weight (Mn) is measured by gel permeation chromatography (GPC). Gel permeation chromatography Alliance GPC-2000 manufactured by Waters Co., Ltd. was used for measurement as follows. The separation column uses two TSKgel GMH6-HT and two TSKgel GMH6-HTL, the column size is 7.5mm in diameter, 300mm in length, the column temperature is set to 140 ° C, and the mobile phase uses o-dichlorobenzene (Wako Pure Chemical Industry) and as Antioxidant BHT (Takeda Pharmaceuticals) 0.025% by weight, made to flow at 1.0ml / min, sample concentration was set to 15mg / 10mL, sample injection volume was set to 500 microliters, and a diff...

manufacture example 1

[0226]

[0227] 1 part by mass of maleic anhydride (manufactured by Fujifilm Wako Pure Chemical Industries, Ltd.), 2,5-dimethyl - 0.25 parts by mass of 2,5-bis(t-butylperoxy)hexyne-3 (manufactured by NOF Corporation, trade name PERHEXYNE 25B), using a twin-screw mixer (manufactured by Nippon Steel Works, TEX- 30, L / D=40, using a vacuum vent), extruded at a barrel temperature of 220° C., a screw rotation speed of 200 rpm, and a discharge rate of 80 g / min to obtain a maleic anhydride-modified polypropylene (B-1). The obtained maleic anhydride-modified polypropylene (B-1) was dissolved in xylene, then the obtained xylene solution was poured into acetone, reprecipitated and purified, and the amount of maleic anhydride grafted was measured by IR. It was measured and found to be 0.7% by mass. Moreover, the number average molecular weight (Mn) measured by GPC was Mn28,000.

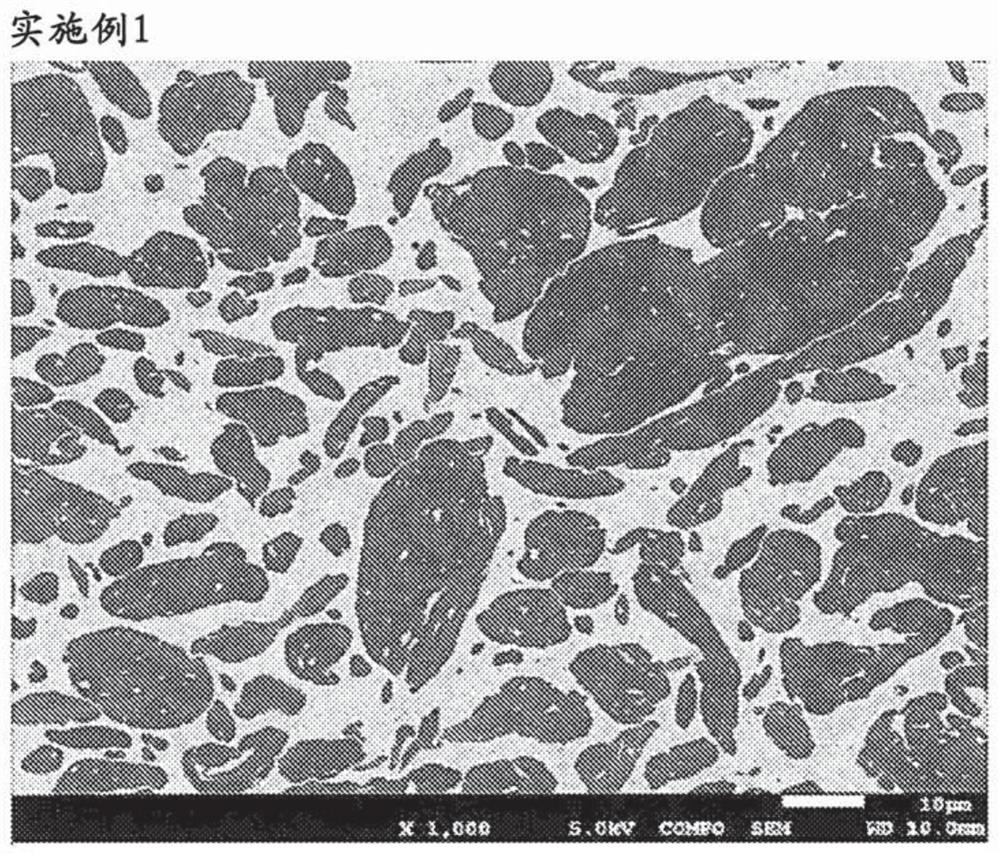

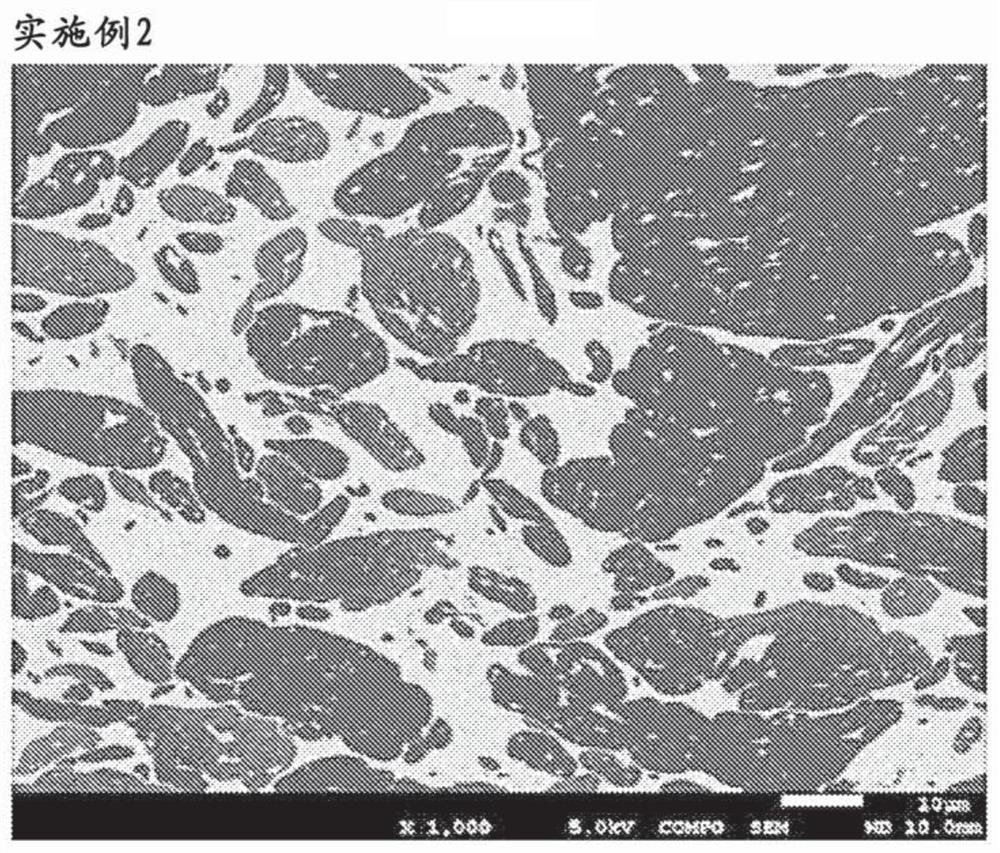

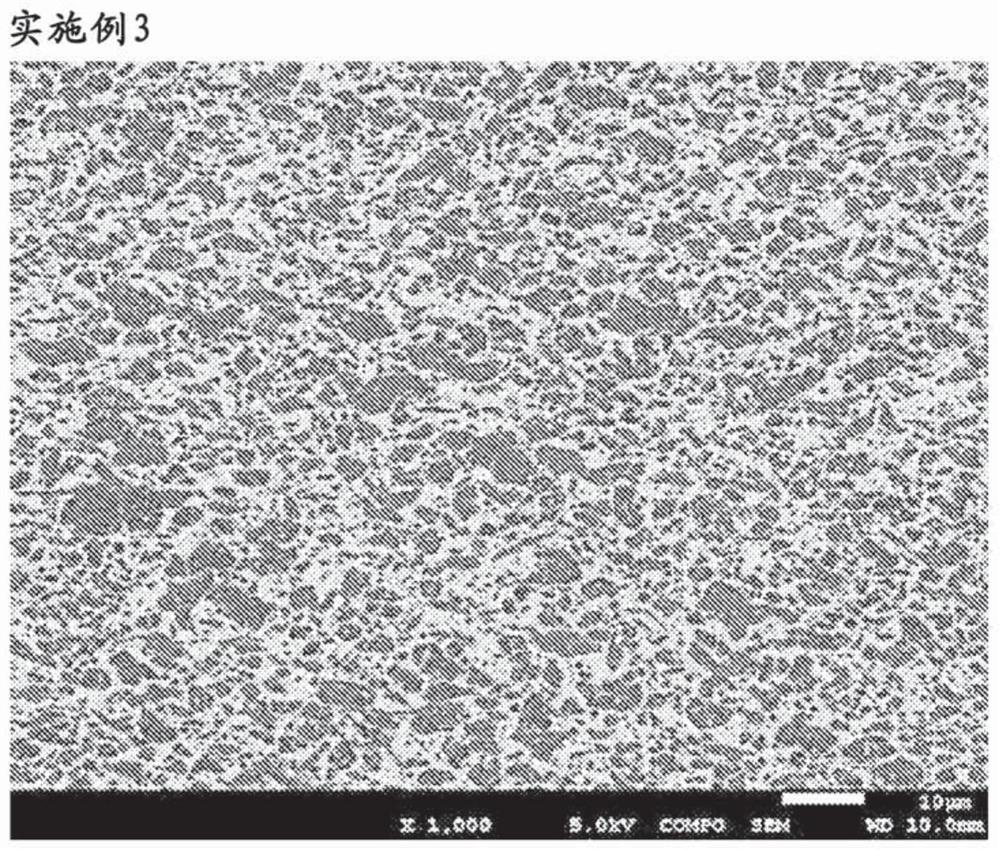

Embodiment 1

[0229] As the first stage, polycarbodiimide (A-1) (manufactured by Nisshinbo Chemical Co., Ltd., trade name: Carbodilite HMV-15CA, carbodiimide equivalent weight 262 g) which is a carbodiimide group-containing compound was used , Maleic anhydride-modified polypropylene (B-1) and polypropylene (D-1) obtained in Production Example 1 (manufactured by Prime Polymer Co., Ltd., trade name PrimePolypro (registered trademark) F113G, MFR: 3.0 g / 10min) The compounding amount (parts by mass) shown in Table 1 was introduced into an extruder (manufactured by Nippon Steel Works, TEX44, L / D=70), and the barrel temperature was 290°C, the screw speed was 760rpm, and the discharge rate was 1.33 kg / min was melt-kneaded to obtain a reaction product (contact) comprising polycarbodiimide (A-1) and maleic anhydride-modified polypropylene (B-1), and polypropylene (D-1 )Compositions.

[0230] Next, as a second stage, nitrile rubber (C-1) (manufactured by Zeon Corporation, Japan, Nipol 1042, NBR, Moon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com