3D printed cobalt-chromium alloy for dental porcelain repair and preparation method thereof

A 3D printing, cobalt-chromium alloy technology, applied in the direction of dentures, additive processing, etc., can solve the problems of low elongation, high strength and hardness, and poor mechanical properties of restorations, which is beneficial to metal-ceramic bonding and low cost. Low, reduce the effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

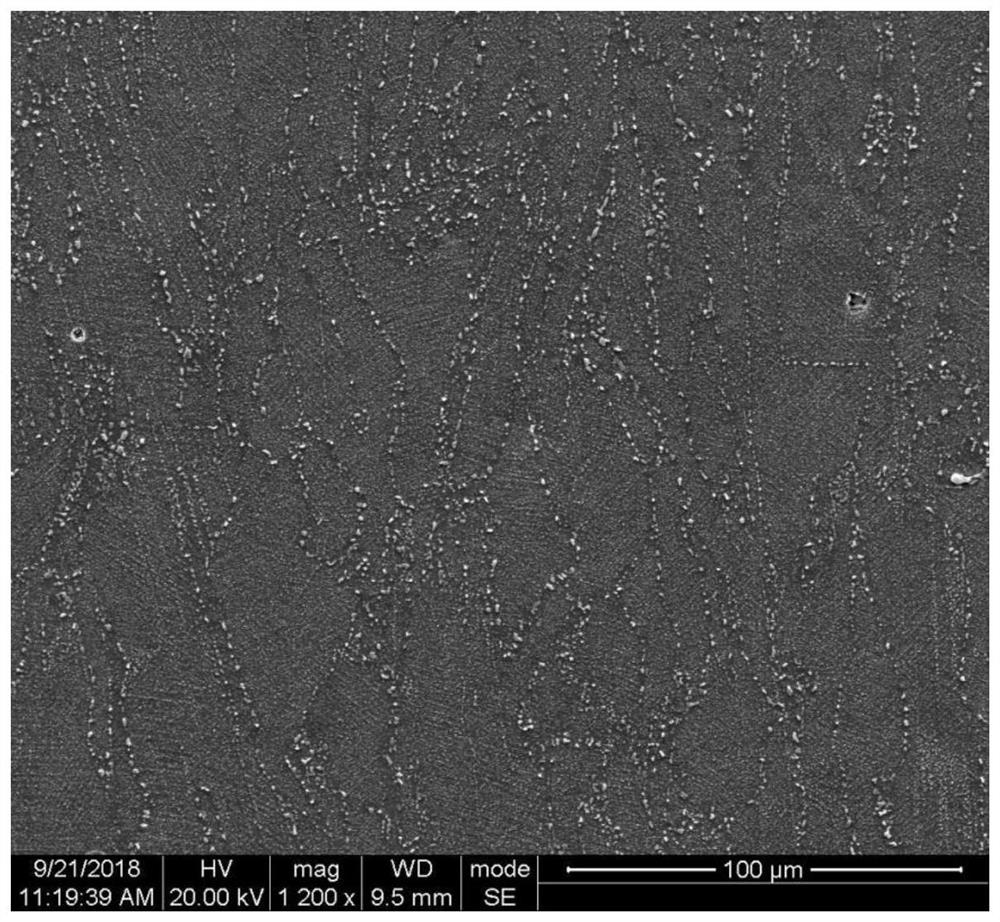

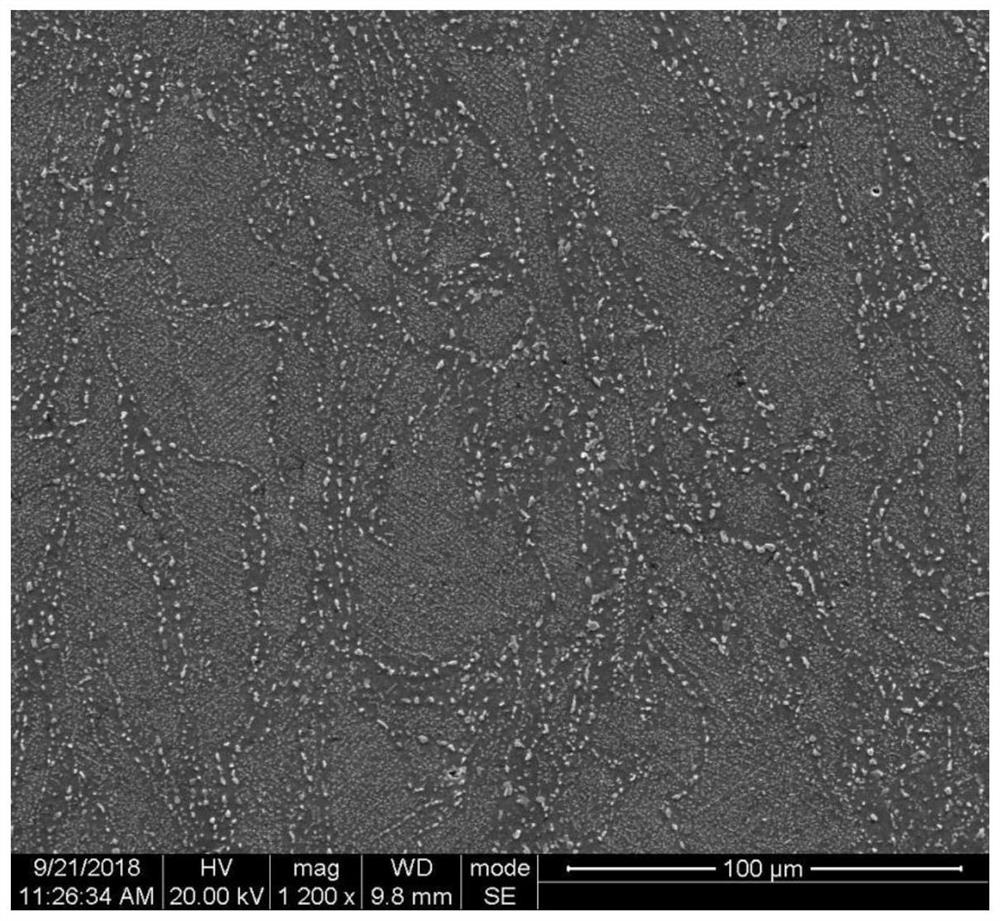

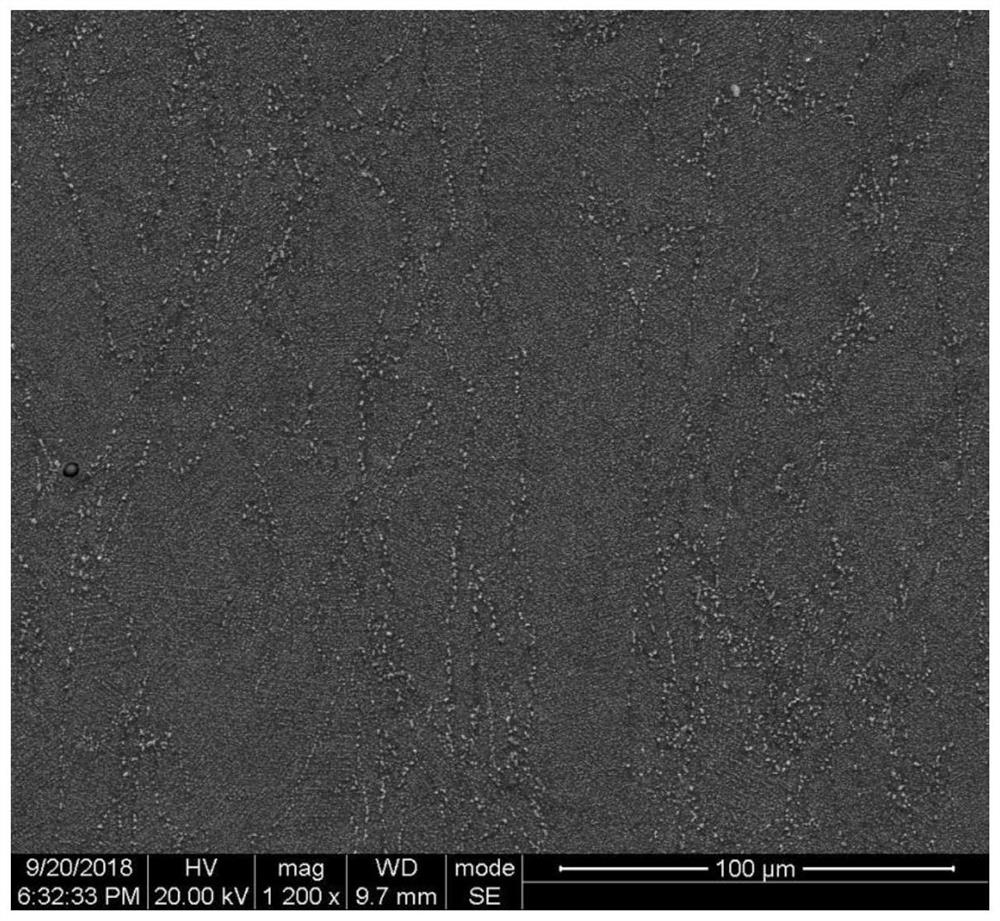

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a 3D printed cobalt-chromium alloy for dental porcelain restoration, comprising the following steps:

[0037] A 3D printing method is used to make a cobalt-chromium porcelain restoration on the substrate, and the cobalt-chromium porcelain restoration includes the following chemical composition in weight percentage: Cr 30-35%, W 4-9%, Mo 4-9%, Si 0.5-2.0%, Ta 5-10%, Nb 0.5-2.0%, the balance of Co and unavoidable impurities, the mass content of the impurities is less than 0.5%;

[0038] The cobalt-chromium porcelain restoration and the substrate are sequentially subjected to vacuum stress-relief annealing and support removal to obtain a cobalt-chromium alloy after stress-relief annealing;

[0039] In a protective atmosphere, the cobalt-chromium alloy after the stress relief annealing is sequentially subjected to solution treatment and aging treatment to obtain the 3D printed cobalt-chromium alloy for dental porcelain restorati...

Embodiment 1

[0062] In this example, the chemical composition of a 3D printed cobalt-chromium alloy for dental porcelain restoration and the weight percentages of each element are: Cr 30.0%, W 5.0%, Mo 5.0%, Si 1.0%, Ta 8.0%, Nb 1.5% , the balance is Co and impurities, and the weight percentage of impurities is less than 0.5%. Carry out heat treatment to cobalt-chromium alloy, specifically comprise the following steps:

[0063] (1) Use laser selective melting (SLM) technology to make cobalt-chromium ceramic alloys with the above chemical composition, then put the formed cobalt-chromium alloy together with the substrate into a vacuum furnace, and first raise the temperature to 600 at a rate of 20°C / min. ℃, keep warm for 45min; then rise to 1100℃ at a rate of 30℃ / min, keep warm for 60min; then cool to room temperature at a rate of 15℃ / min.

[0064] (2) Cutting the cobalt-chromium ceramic alloy annealed in step (1) from the substrate, and removing the support.

[0065] (3) Put the cobalt-ch...

Embodiment 2

[0069] In this example, the chemical composition of a 3D printed cobalt-chromium alloy for dental porcelain restoration and the weight percentages of each element are: Cr 32.0%, W 6.0%, Mo 7.0%, Si 1.5%, Ta 5.0%, Nb 0.5% , the balance is Co and impurities, and the weight percentage of impurities is less than 0.5%. Carry out heat treatment to cobalt-chromium alloy, specifically comprise the following steps:

[0070] (1) Use laser selective melting (SLM) technology to make cobalt-chromium ceramic alloys with the above chemical composition, then put the formed cobalt-chromium alloy together with the substrate into a vacuum furnace, and first raise the temperature to 550 at a rate of 25°C / min. ℃, keep warm for 50min; then raise the temperature to 1150℃ at a rate of 25℃ / min, keep warm for 70min; then cool to room temperature at a rate of 5℃ / min.

[0071] (2) Cutting the cobalt-chromium ceramic alloy annealed in step (1) from the substrate, and removing the support.

[0072] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com