Silicon-containing thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and plastic polyurethane technology, applied in the field of silicon-containing thermoplastic polyurethane elastomer and its preparation, can solve the problems of high production cost and low production efficiency of silicon-containing TPU, and achieve production efficiency improvement, excellent coating and surface touch. , excellent wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

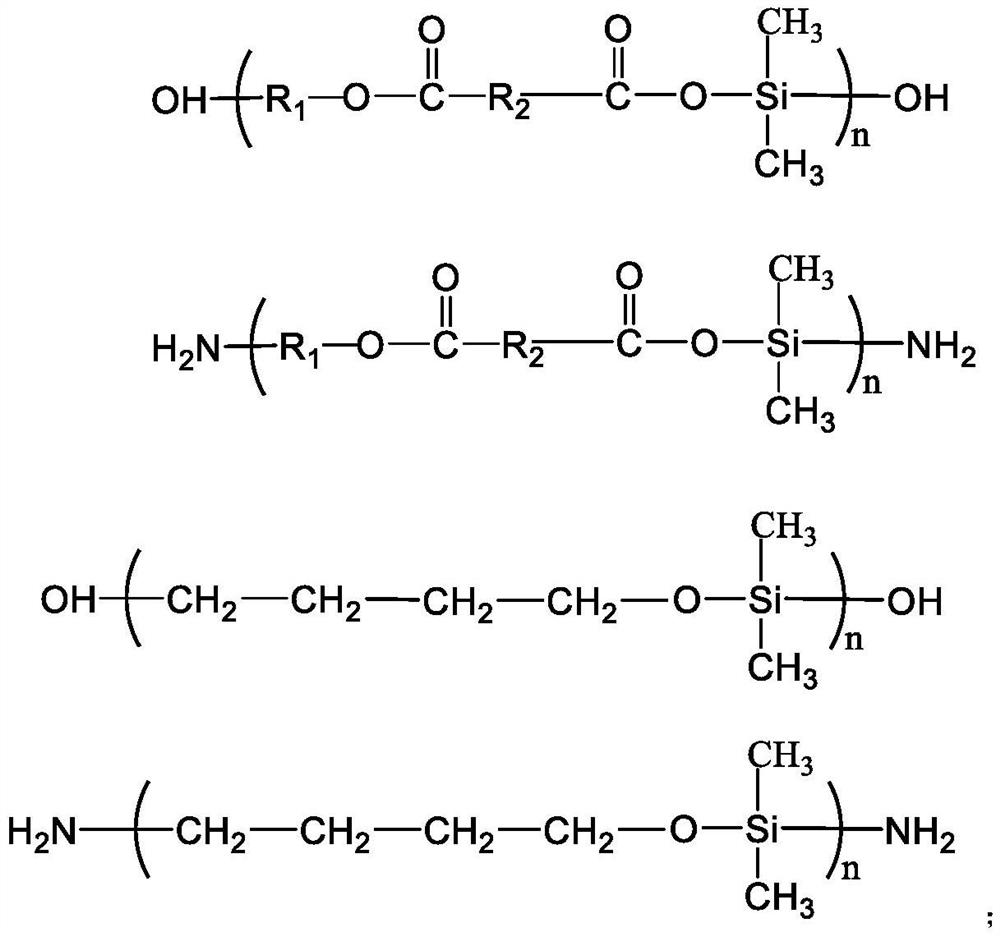

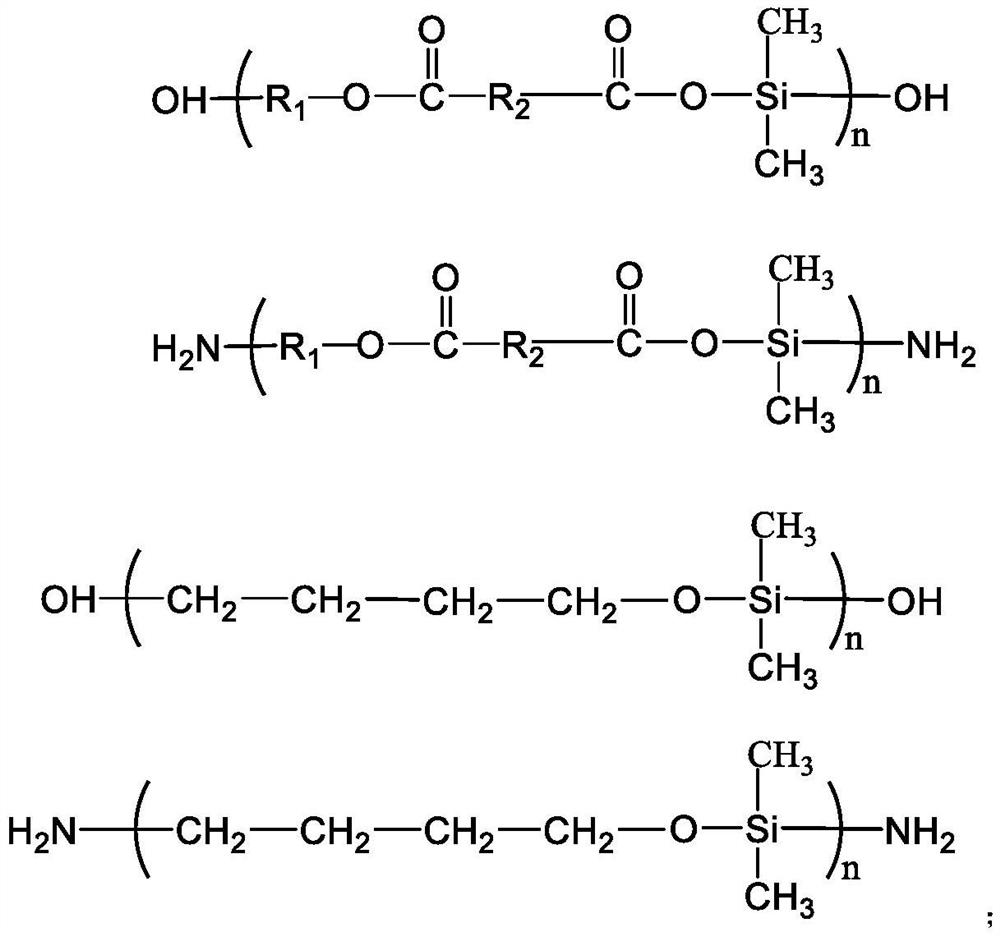

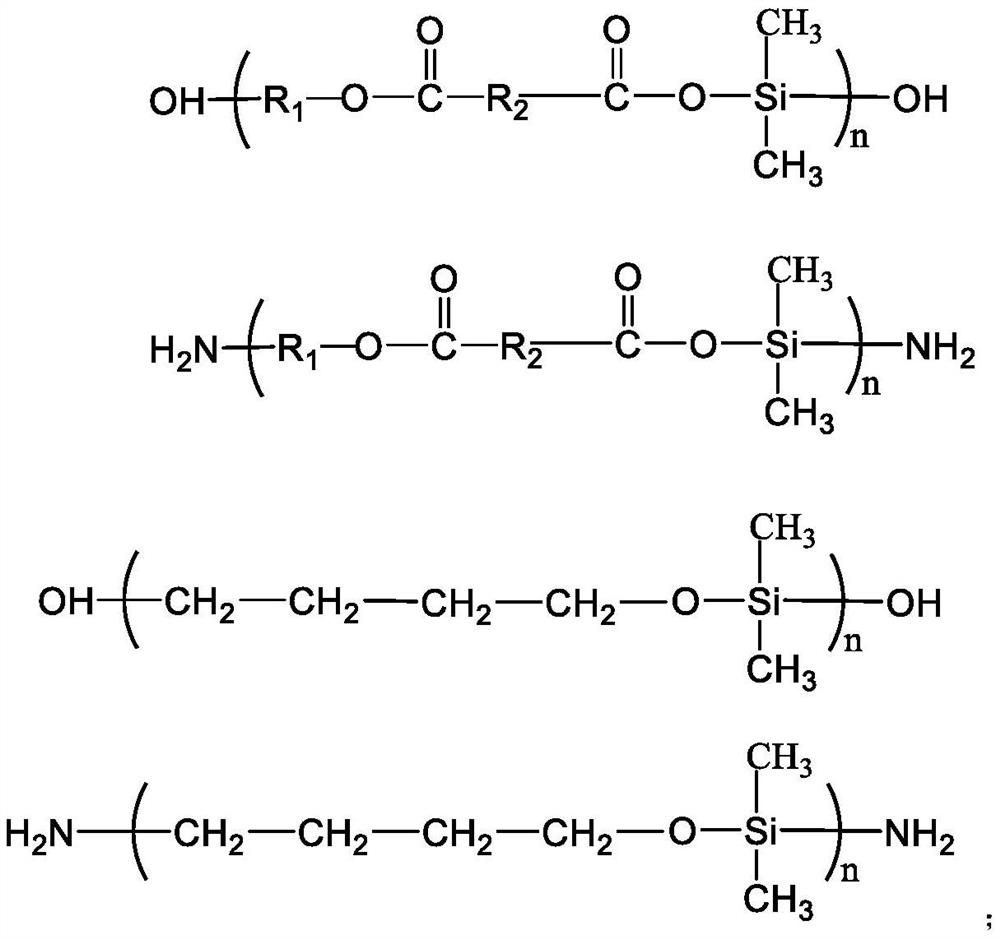

[0047] A preparation method of silicon-containing thermoplastic polyurethane elastomer, said method comprising the steps of:

[0048] Step 1: Mix diisocyanate, chain extender, polyol, and group-containing silicone oil in a twin-screw extruder. The temperature of the twin-screw extruder is 140-250 degrees, and the screw speed is 150-350RPM;

[0049] Step 2: Extrude the mixed material through reaction;

[0050] Step 3: Cut the extruded material into pellets under water to obtain silicon-containing TPU pellets.

Embodiment 1

[0064]According to the mass ratio, 53.87% of polyols (PTMEG2000) with a functionality of 2, 29.95% of diphenylmethane diisocyanate (MDI), 7.48% of aliphatic diols (BDO), and 8.7% of hydroxyl-terminated high Pouring with active silicone oil, in which the temperature of the polyol (PTMEG2000) component is controlled at 95 °C, and the temperature of diphenylmethane diisocyanate (MDI) and aliphatic diol (BDO) is both controlled at 50 °C;

[0065] Add the antioxidant (1010) of 0.3%PTMEG2000 weight again, the antioxidant (168) of 0.2%PTMEG2000 weight, the lubricant (E wax) of 0.2%PTMEG2000 weight, the anti-UV agent (201) of 0.4%PTMEG2000 weight, The ultraviolet absorber (144) of 0.2% PTMEG2000 weight and the catalyst (stannous octoate) of 45ppm PTMEG2000 weight;

[0066] Set the temperature of the 13 zones of the twin-screw extruder as 120°C, 180°C, 185°C, 190°C, 190°C, 185°C, 170°C, 160°C, 150°C, 150°C, 150°C, 160°C , 170°C, the screw speed is 220rpm;

[0067] After the reaction ...

Embodiment 2

[0070] According to the mass ratio, 53.87% of polyols (PTMEG2000) with a functionality of 2, 29.95% of diphenylmethane diisocyanate (MDI), 7.48% of aliphatic diols (BDO), and 8.7% of amino-terminated high Pouring with active silicone oil, in which the temperature of the polyol (PTMEG2000) component is controlled at 95 °C, and the temperature of diphenylmethane diisocyanate (MDI) and aliphatic diol (BDO) is both controlled at 50 °C;

[0071] Add the antioxidant (1010) of 0.3%PTMEG2000 weight again, the antioxidant (168) of 0.2%PTMEG2000 weight, the lubricant (E wax) of 0.2%PTMEG2000 weight, the anti-UV agent (201) of 0.4%PTMEG2000 weight, The ultraviolet absorber (144) of 0.2% PTMEG2000 weight and the catalyst (stannous octoate) of 45ppm PTMEG2000 weight;

[0072] Set the temperature of the 13 zones of the twin-screw extruder as 120°C, 180°C, 185°C, 190°C, 190°C, 185°C, 170°C, 160°C, 150°C, 150°C, 150°C, 160°C , 170°C, the screw speed is 220rpm;

[0073] After the reaction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com