Preparation method of aluminum oxide-silicon dioxide composite ceramic membrane

A composite ceramic membrane and silicon dioxide technology, which is applied in the field of preparation of alumina-silica composite ceramic membranes, can solve the problems of unstable performance of composite ceramic membranes, difficult to control, harsh process parameters for composite sol preparation, etc. The effect of morphology and properties, short film forming cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 1.202g of aluminum trichloride powder and pour it into a beaker, measure 90ml of ammonia water with a concentration of 1mol / L into the beaker, place it in a water bath at 80°C for hydrolysis and stir, then add 1.0g of PVA to the beaker, Add 2 ml of hydrochloric acid dropwise to the beaker to adjust the pH value, control the pH value of the reaction solution to 3, continue stirring in the water bath for 1.5 hours to obtain the aluminum sol.

[0037]Measure 2ml of tetraethyl orthosilicate and pour it into a beaker, measure 90ml of absolute ethanol into the beaker, stir rapidly while adding dropwise, and add 2ml of dilute nitric acid to adjust the pH to 3. Then, 2ml of 1mol / L ammonia water was added dropwise into the beaker, and stirred in a constant temperature water bath at 80°C for 2.5 hours to obtain the desired silica sol.

[0038] At room temperature, mix aluminum sol and silica sol according to the molar ratio of aluminum to silicon of 4:1, add 3ml of nitric a...

Embodiment 2

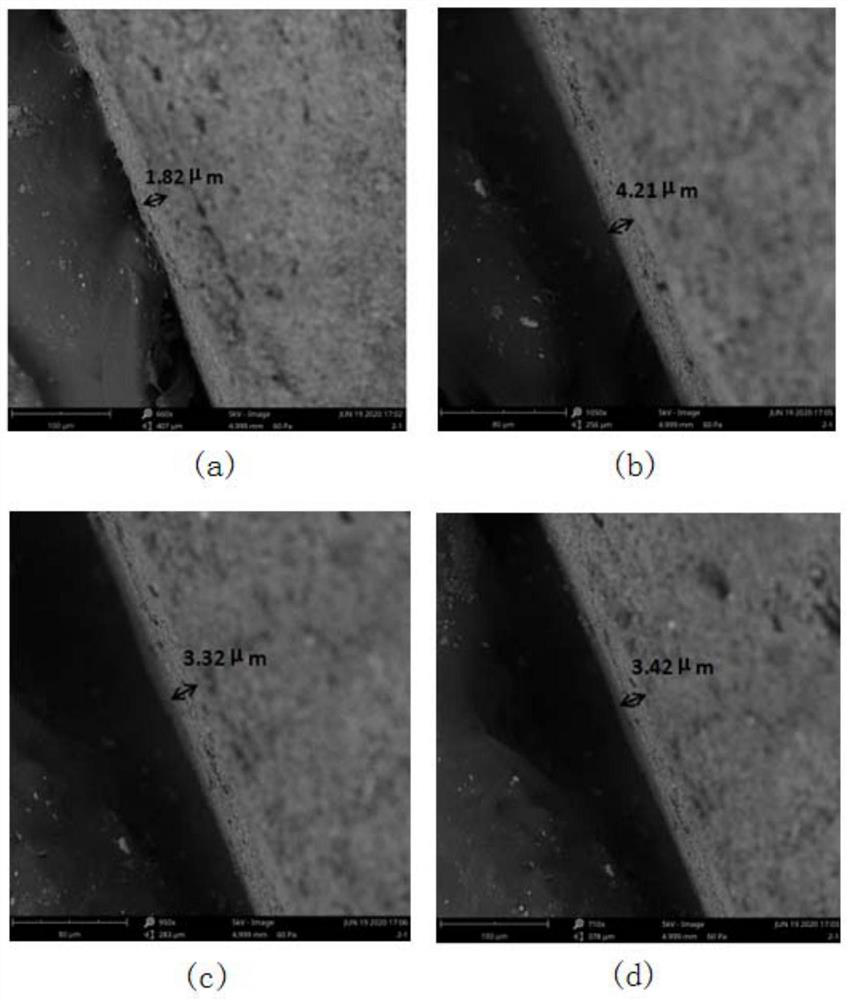

[0041] At room temperature, mix aluminum sol and silica sol at a ratio of 1:4 (the same molar ratio of aluminum to silicon), add 3ml of nitric acid, heat and stir in a constant temperature water bath, and obtain a composite sol after aging. Others are the same as implementation example 1. The ceramic membrane thus prepared has a thickness of 3.43 μm, a pore size of 1.7 nm, a porosity of 28.4%, and a permeation flux of 3.73 mL cm -2 min -1 .

Embodiment 3

[0043] At room temperature, mix aluminum sol and silica sol at a ratio of 3:1 (the same molar ratio of aluminum to silicon), add 3ml of nitric acid, heat and stir in a constant temperature water bath, and obtain a composite sol after aging. Others are the same as implementation example 1. The ceramic membrane thus prepared has a thickness of 3.32 μm, a pore size of 1.6 nm, a porosity of 26.6%, and a permeation flux of 3.52 mL cm -2 min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com