Red high-thixotropy UV adhesive for manufacturing washers and preparation method thereof

A high thixotropic, red technology, applied in the field of UV glue, can solve the problems of difficult prefabricated solid sealing rings, etc., and achieve the effects of excellent elasticity and sealing performance, reasonable formula ratio, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, preparation method one for making the red high thixotropic UV glue of gasket:

[0057] Raw material composition:

[0058] Polyurethane acrylic resin 46%;

[0059] 2,4,6(trimethylbenzoyl)diphenylphosphine oxide 0.25%;

[0060] 1-Hydroxycyclohexyl phenyl ketone 1%;

[0061] N,N-dimethylacrylamide 5%;

[0062] 2-phenoxyethyl acrylate 30%;

[0063] Tetrahydrofuran acrylate 12.1%;

[0064] Phosphodiester methacrylate 0.5%;

[0065] Fumed silica 5%;

[0066] Pigment Red 171 (PR171) 0.15%;

[0067] Preparation method: Add the raw materials in the above proportions into the stirring tank one by one, stir evenly, vacuumize to remove air bubbles, and store in the dark after packaging.

Embodiment 2

[0068] Embodiment 2, the preparation method two of the red high thixotropic UV glue that is used to make gasket:

[0069] Raw material composition:

[0070] Polyurethane acrylic resin 42%;

[0071] 2,4,6(trimethylbenzoyl)diphenylphosphine oxide 0.25%;

[0072] 1-Hydroxycyclohexyl phenyl ketone 1 %;

[0073] N,N-dimethylacrylamide 4%;

[0074] Lauryl acrylate 8%;

[0075] 2-phenoxyethyl acrylate 38%;

[0076] Phosphodiester methacrylate 0.5%;

[0077] After the above raw materials are added to the stirring tank and stirred evenly, add 6% of fumed silica and 0.25% of Pigment Red 171 (PR171), stir evenly, vacuumize to remove air bubbles, pack and store away from light.

Embodiment 3

[0078] Embodiment 3, the preparation method three of the red high thixotropic UV glue that is used to make gasket:

[0079] Raw material composition:

[0080] Polyurethane acrylic resin 37%;

[0081] 2,4,6(trimethylbenzoyl)diphenylphosphine oxide 0.2%;

[0082] 1-Hydroxycyclohexyl phenyl ketone 0.8 %;

[0083] N,N-dimethylacrylamide 4.3%;

[0084] Lauric acid acrylate 8.6%;

[0085] Hydroxybutyl acrylate 12.35%;

[0086] 2-phenoxyethyl acrylate 30%;

[0087] Phosphodiester methacrylate 0.5%;

[0088] Put the above raw materials into the stirring tank one by one, stir well, add fumed silica 6%, pigment red 171 (PR171) 0.25%, stir well, vacuumize to remove air bubbles, pack and store away from light.

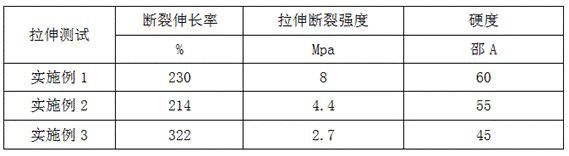

[0089] The red highly thixotropic UV obtained in Examples 1-3 was used for related tests, and the results are as follows:

[0090] Table 1 Tensile test results of cured strips at room temperature

[0091]

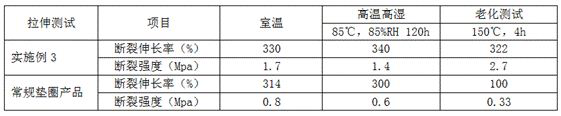

[0092] The cured sample was tested at 85°C, 85%RH, and 120h. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com