Blast furnace cloth bag ash resource utilization process method

A process method, the technology of bag ash, applied in the field of waste resource utilization, can solve the problems of unfavorable iron and steel enterprises, such as energy saving and consumption reduction, huge investment and operating costs, and the generation of electrolytic wastewater, so as to achieve high selective leaching function and increase income. The effect of low efficiency and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

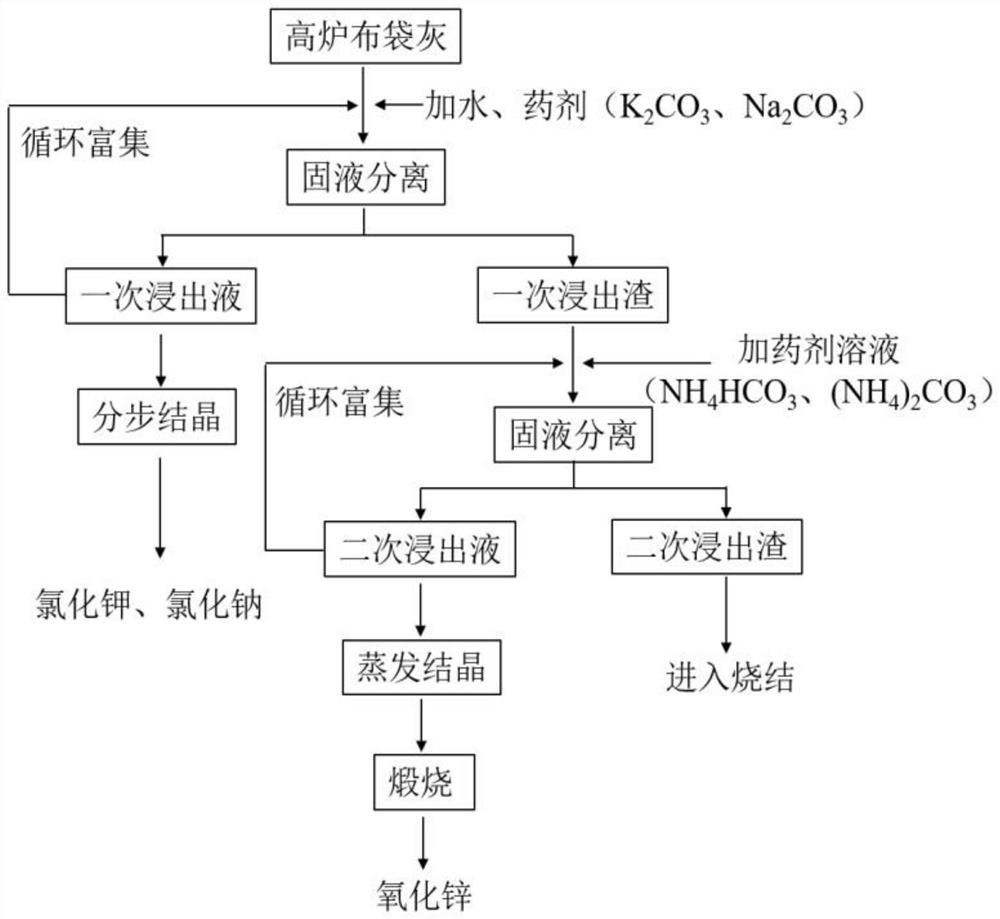

[0050] A process method for resource utilization of blast furnace bag ash specifically includes:

[0051] 1. The process steps of adding medicament, water washing and fractional crystallization to recover potassium chloride and sodium chloride specifically include:

[0052] (1), grind the blast furnace bag ash until the particle size is less than 200 mesh, then mix water and blast furnace bag ash according to the liquid-solid ratio of 6:1 by mass, and add 0.5mol / L potassium carbonate solution to obtain the solid The liquid mixture was stirred at a speed of 360r / min for 10min;

[0053] (2) Filtrate the solid-liquid mixture that has been stirred well and uniformly to obtain primary leaching liquid and primary leaching slag. When the chlorine content in the primary leaching solution is lower than 15wt% water, return to the previous step for water washing; when the chlorine content in the primary leaching solution is higher than 15wt% water, it is used for the next step of ammoni...

Embodiment 2

[0063] 1. The process steps of adding medicament, water washing and fractional crystallization to recover potassium chloride and sodium chloride specifically include:

[0064] (1), grind the blast furnace bag ash until the particle size is less than 200 mesh, then mix water and blast furnace bag ash according to the liquid-solid ratio of 6:1 by mass, and add 0.5mol / L sodium carbonate solution to obtain the solid The liquid mixture was stirred at a speed of 360r / min for 10min;

[0065] (2) Filtrate the solid-liquid mixture that has been stirred well and uniformly to obtain primary leaching liquid and primary leaching slag. When the chlorine content in the primary leaching solution is lower than 15wt% water, return to the previous step for water washing; when the chlorine content in the primary leaching solution is higher than 15wt% water, it is used for the next step of ammonia washing; after the primary leaching solution enriched in potassium chloride is purified and removed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com