A kind of short fiber reinforced carbon/resin composite material hot pressing molding demoulding method

A technology of resin composite material and short fiber reinforcement, which is applied in the field of carbon/carbon composite material and its preparation, can solve the problems of affecting the surface quality of the green body, affecting the mold fit, and large demoulding resistance, etc., to improve the resistance to hot pressing and pressing Mosaic performance, reduced demoulding resistance, easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

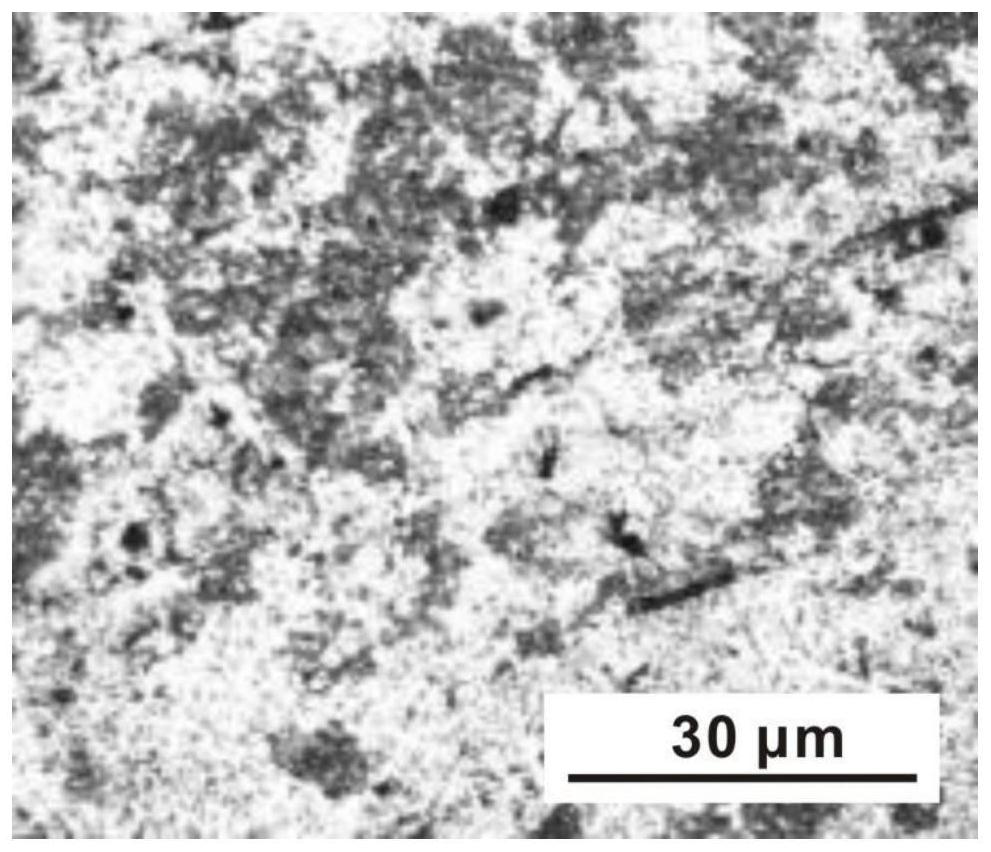

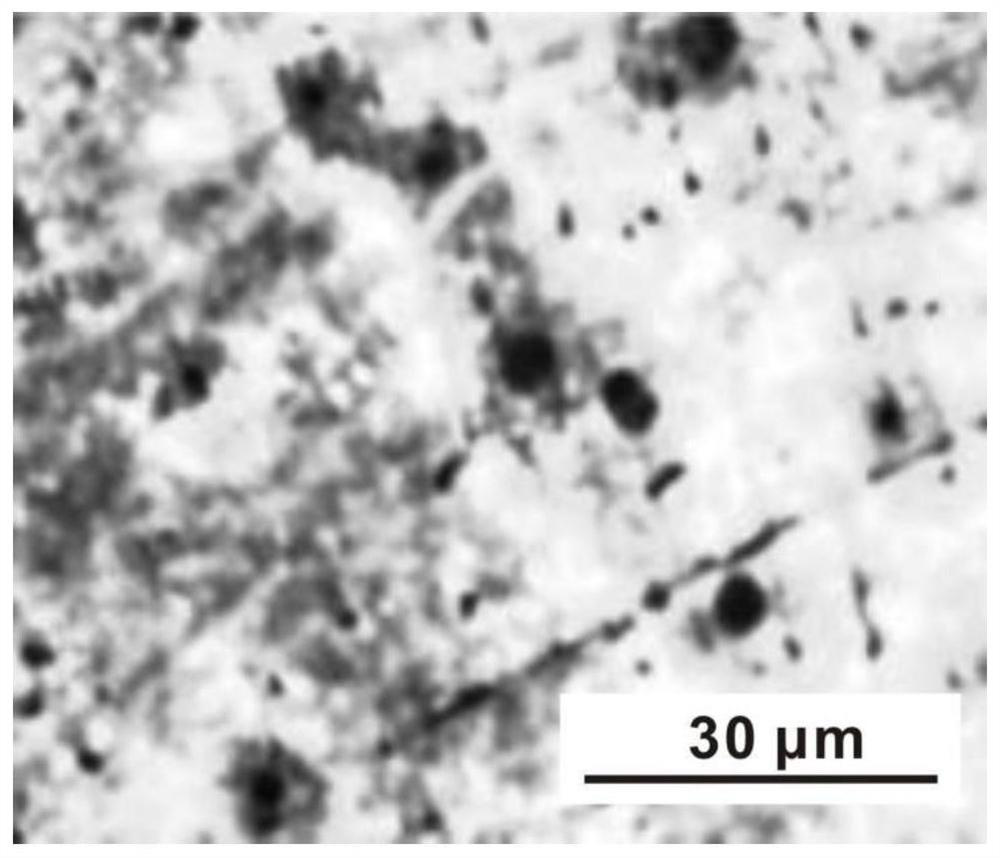

Image

Examples

Embodiment 1

[0027] A short-fiber reinforced carbon / resin composite material hot-pressing and demolding method, comprising (1) adding a surface-treated 65Mn separator between a blank and upper and lower die punches during hot-pressing, and (2) placing a Use mold release agent on the contact surface between the inner wall of the mold and the 65Mn separator and the body;

[0028] The 65Mn separator adopts the carbonitride (C, N) co-infiltration method for surface treatment, which specifically includes the following steps:

[0029] (a) In the pit furnace, drip methanol at a speed of 80 drops / min, and feed ammonia gas at a speed of 350 L / h, control the temperature to be about 830 °C, and the time is 3 hours;

[0030] (b) After carbonitriding, oil is cooled to room temperature and then quenched + tempered at medium temperature. The quenching temperature is 830°C. After holding for 20min, the oil is cooled to room temperature and tempered at 430°C for 2h.

[0031] The mold release agent contain...

Embodiment 2

[0038] A short-fiber reinforced carbon / resin composite material hot-pressing and demolding method, comprising (1) adding a surface-treated 65Mn separator between a blank and upper and lower die punches during hot-pressing, and (2) placing a Use mold release agent on the contact surface between the inner wall of the mold and the 65Mn separator and the body;

[0039] The 65Mn separator adopts the carbonitride (C, N) co-infiltration method for surface treatment, which specifically includes the following steps:

[0040] (a) In the pit furnace, drip methanol at a speed of 100 drops / min, and feed ammonia gas at a speed of 500 L / h, control the temperature to be about 830 °C, and the time is 2 hours;

[0041] (b) After carbonitriding, oil is cooled to room temperature and then quenched + tempered at medium temperature. The quenching temperature is 830°C. After holding for 20min, the oil is cooled to room temperature and tempered at 430°C for 2h.

[0042] The mold release agent contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com