A production method of economical cold-rolled steel plate for water heater water tank outer plate

A technology for water heater water tank and cold-rolled steel plate, applied in metal rolling and other directions, can solve the problems of unspecialized control of plate shape, low yield strength, difficult welding, etc., and achieve the effects of reasonable composition design, short process flow and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

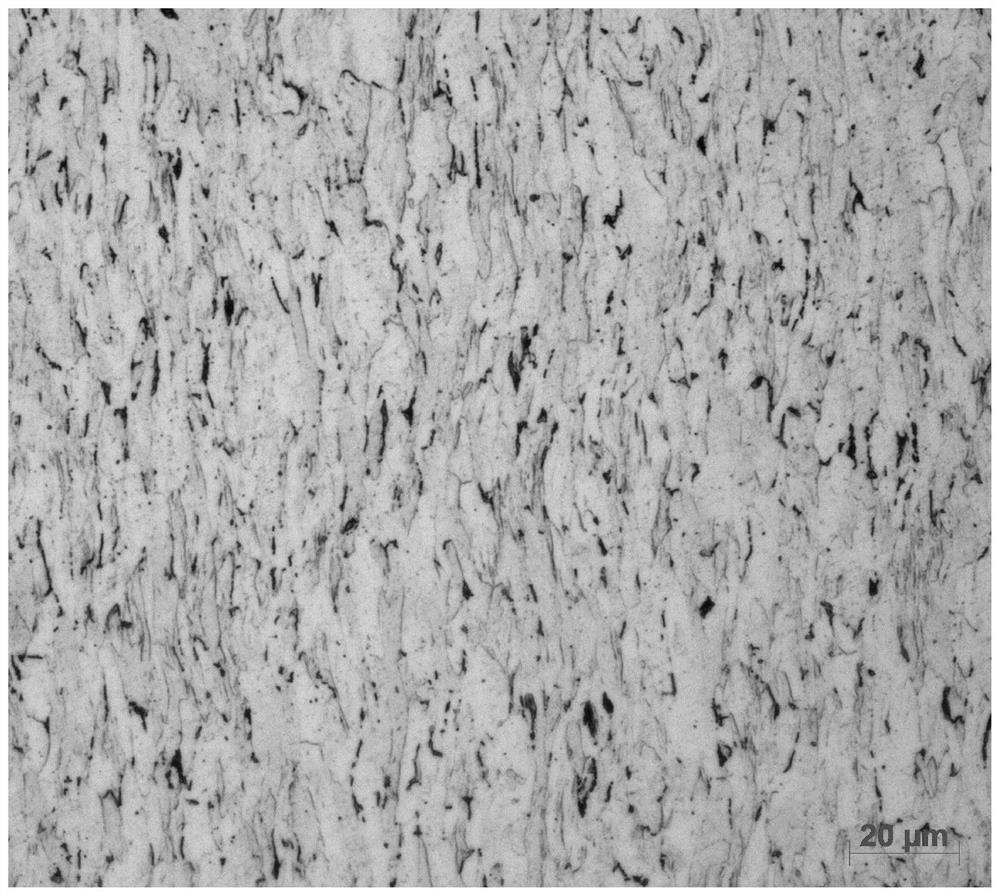

Image

Examples

Embodiment 1

[0024] The smelting composition is controlled as follows: C=0.040%, Mn=0.25%, Si=0.010%, P=0.011%, S=0.012%, Als=0.029%, and the balance is Fe and other residual trace elements.

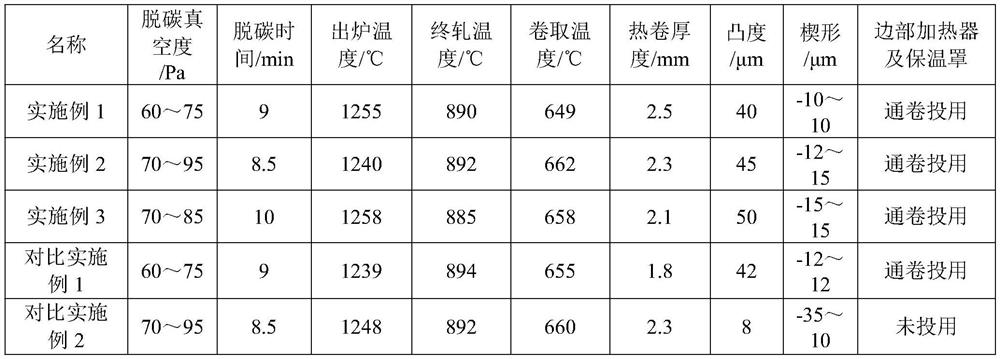

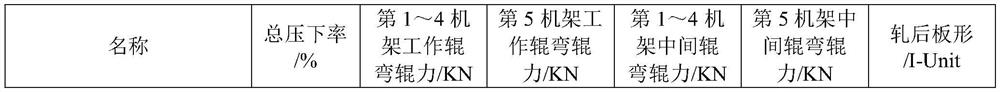

[0025] The process control of the whole process is as follows: the vacuum degree of RH refining decarburization in the steelmaking process is 60-75Pa, the decarburization time is 9min, and then the slab with a thickness of 230mm is continuously cast. Hot rolling process red delivery, slab exit temperature 1255°C, finish rolling temperature 890°C, coiling temperature 649°C, edge heater and heat preservation cover are used for coil passing, hot rolled coil thickness 2.5mm, crown 40μm, wedge- 10-10 μm. The total reduction rate of cold continuous rolling in the acid rolling process is 84.0%, and the rolling is controlled by micro-medium waves. The bending force of the work rolls of the 1st to 4th stands is 100-250KN, and the bending force of the work rolls of the 5th stand is 200-500KN. The bending forc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com