Preparation method of sympathetic detonation prevention polyurea coating for projectile body

A technology of explosive polymerization and projectiles, which is applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of ammunition detonation, etc., and achieve the effects of maintaining strength performance, good weather resistance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

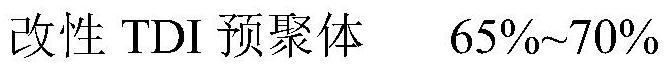

[0026] An anti-explosion polyurea coating for projectiles, the components and the mass percentages thereof are as follows:

[0027]

[0028] Weigh 600g of TDI prepolymer, 150g of silicon carbide ceramic powder, 45g of organic zirconate coupling agent and 3000g of tetrahydrofuran solution according to the mass ratio, add the organic zirconate coupling agent into the tetrahydrofuran solution, and ultrasonically disperse for 30 minutes. Obtain mixed solution A; then add TDI prepolymer and silicon carbide ceramic powder into mixed solution A, perform mechanical stirring at a stirring rate of 300-500r / min, and obtain mixed solution B after 1-2 hours; mix mixed solution B After suction filtration, put it into a blast oven at 70-80°C for drying, take it out for 2-3 hours and grind it finely to obtain 789.67g of modified TDI prepolymer;

[0029] Weigh 10g of sisal cellulose powder, 40g of ammonium polyphosphate, 10g of montmorillonite, 4.2g of organic zirconate coupling agent and 1...

Embodiment 2

[0034] An anti-explosion polyurea coating for projectiles, the components and the mass percentages thereof are as follows:

[0035]

[0036] Weigh 600g of TDI prepolymer, 150g of silicon carbide ceramic powder, 45g of organic zirconate coupling agent and 3000g of tetrahydrofuran solution according to the mass ratio, add the organic zirconate coupling agent into the tetrahydrofuran solution, and ultrasonically disperse for 30 minutes. Obtain mixed solution A; then add TDI prepolymer and silicon carbide ceramic powder into mixed solution A, perform mechanical stirring at a stirring rate of 300-500r / min, and obtain mixed solution B after 1-2 hours; mix mixed solution B After suction filtration, put it into a blast oven at 70-80°C for drying, take it out for 2-3 hours and grind it finely to obtain 788.73g of modified TDI prepolymer;

[0037]Weigh 8g of sisal cellulose powder, 32g of ammonium polyphosphate, 8g of montmorillonite, 3.3g of organic zirconate coupling agent and 80g ...

Embodiment 3

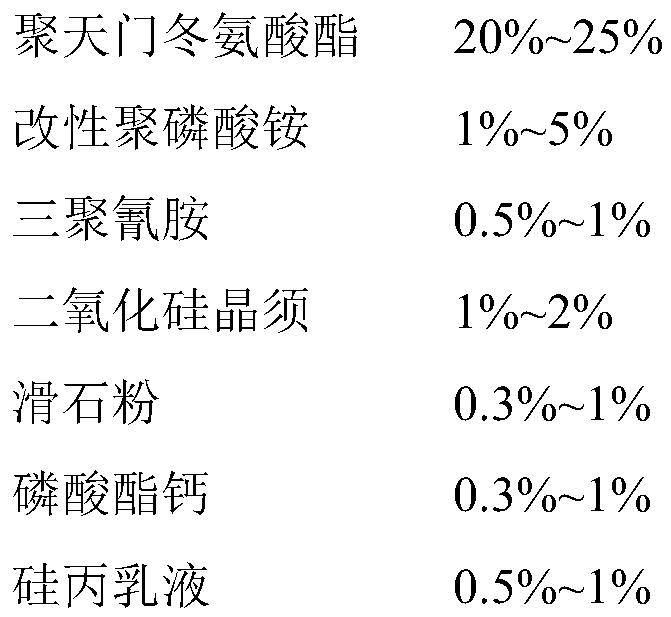

[0042] An anti-explosion polyurea coating for projectiles, the components and the mass percentages thereof are as follows:

[0043]

[0044]

[0045] Weigh 600g of TDI prepolymer, 150g of silicon carbide ceramic powder, 45g of organic zirconate coupling agent and 3000g of tetrahydrofuran solution according to the mass ratio, add the organic zirconate coupling agent into the tetrahydrofuran solution, and ultrasonically disperse for 30 minutes. Obtain mixed solution A; then add TDI prepolymer and silicon carbide ceramic powder into mixed solution A, perform mechanical stirring at a stirring rate of 300-500r / min, and obtain mixed solution B after 1-2 hours; mix mixed solution B After suction filtration, put it into a blast oven at 70-80°C for drying, take it out for 2-3 hours and grind it finely to obtain 788.82g of modified TDI prepolymer;

[0046] Weigh 4.5g of sisal cellulose powder, 18g of ammonium polyphosphate, 4.5g of montmorillonite, 1.6g of organic zirconate coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com