Preparation method and application of spinel structure and layered structure cobalt-free composite material

A technology with a spinel structure and a layered structure, which is applied to structural parts, active material electrodes, electrical components, etc., can solve problems such as difficult interface reactions, high residual alkali content on the surface, and poor rate performance, and achieve improved battery performance. Safety performance, reduction of residual alkali on the surface, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

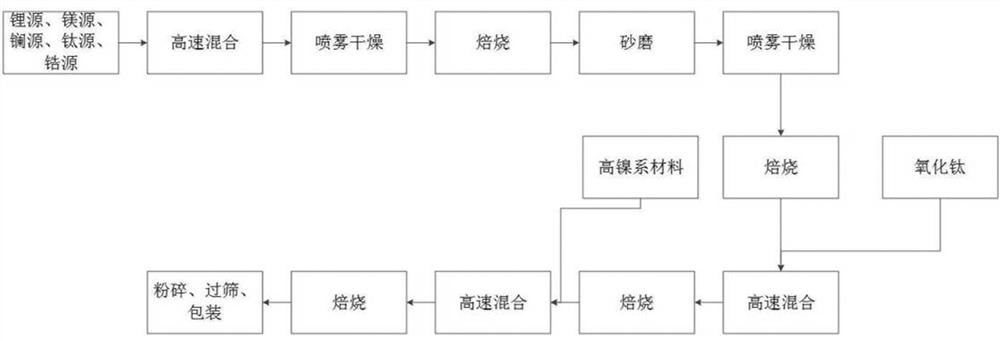

[0032] Such as figure 1 As shown, the invention provides a method for preparing a spinel structure and a layered structure cobalt-free composite material, comprising the steps of:

[0033] 1) In terms of element molar ratio, take manganese source and nickel source with Mn:Ni=1:3, mix them with deionized water and add them into a sand mill for grinding to obtain slurry I, the particle size of slurry I is D 50 ≤0.1μm;

[0034] 2) The ternary precursor Ni x mn (1-x) (OH) 2 Add to the above-mentioned slurry I and mix evenly to obtain slurry II, wherein Ni x mn (1-x) (OH) 2 Amount of substance / (amount of manganese substance+nickel substance in slurry I)=(98.5~99.5):1;

[0035] 3) Spray drying the slurry II to obtain the material III, and the spray drying temperature is 250-450°C;

[0036] 4) Mix the material III and lithium hydroxide uniformly in a high-speed mixer to obtain material IV, wherein the amount of lithium hydroxide substance=(1.02~1.04)*(amount of manganese subs...

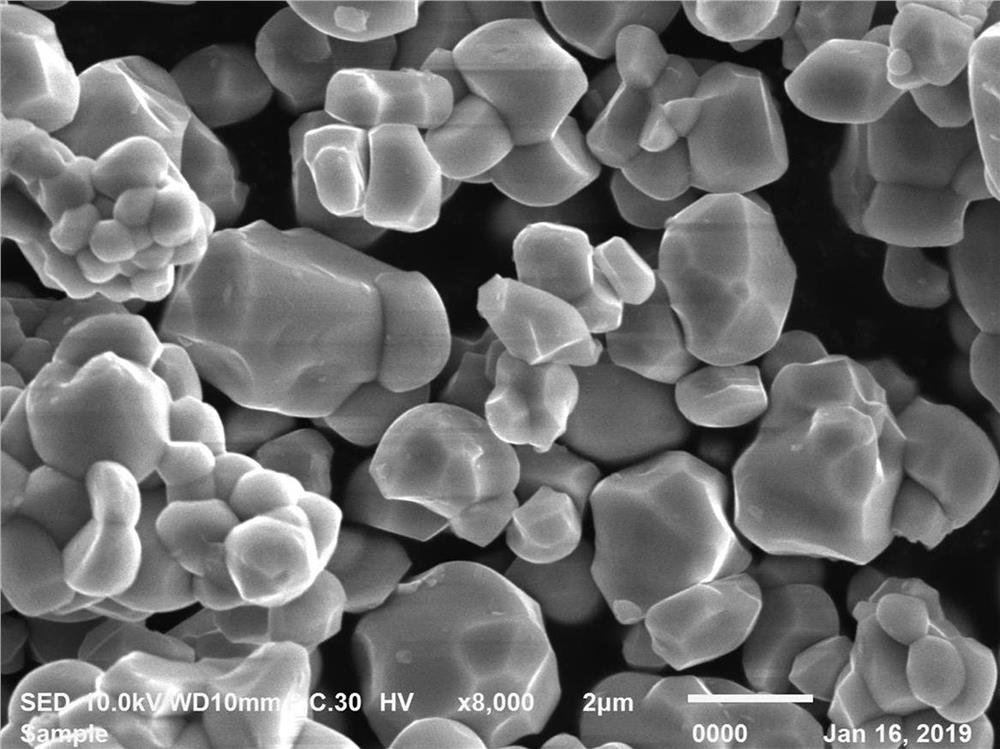

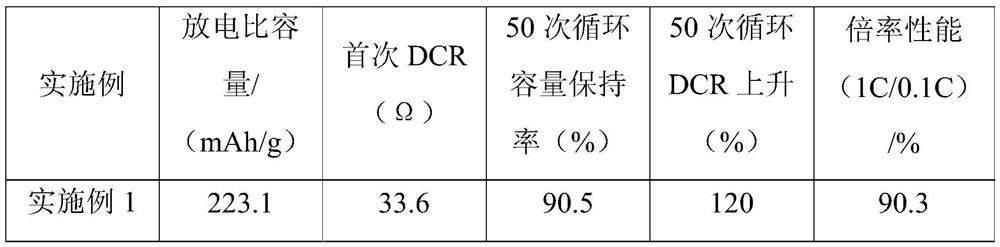

Embodiment 1

[0050] A method for preparing a spinel structure and a layered structure cobalt-free composite material, comprising the steps of:

[0051] 1) Weigh manganese carbonate, nickel hydroxide, and deionized water according to the amount ratio of nickel to manganese to 1:3, and add them into a sand mill for grinding to obtain slurry I and slurry particle size D 50 = 0.08 μm;

[0052] 2) The ternary precursor Ni 0.75 mn 0.25 (OH) 2 Add to the above-mentioned slurry I and mix evenly to obtain slurry II, wherein Ni 0.75 mn 0.25 (OH) 2 The amount of substance / (the amount of manganese substance+the amount of nickel substance in slurry I)=98.5:1;

[0053] 3) Spray-dry the above-mentioned slurry II to obtain material III, and the spray-drying temperature is 250° C.;

[0054] 4) Mix the above-mentioned material III and lithium hydroxide uniformly in a high-speed mixer to obtain material IV, wherein the amount of lithium hydroxide substance=1.02*(the amount of manganese substance in sl...

Embodiment 2

[0066] A method for preparing a spinel structure and a layered structure cobalt-free composite material, comprising the steps of:

[0067] 1) Weigh manganese trioxide, nickel hydroxide, and deionized water according to the amount ratio of nickel to manganese to 1:3, and add them into a sand mill for grinding to obtain slurry I and slurry particle size D 50 = 0.06 μm;

[0068] 2) The ternary precursor Ni 0.8 mn 0.2 (OH) 2 Add to the above-mentioned slurry I and mix evenly to obtain slurry II, wherein Ni 0.8 mn 0.2 (OH) 2 The amount of substance / (the amount of manganese substance+nickel substance in slurry I)=99.5:1;

[0069] 3) Spray-dry the above-mentioned slurry II to obtain material III, and the spray-drying temperature is 300° C.;

[0070] 4) Mix the above-mentioned material III and lithium hydroxide uniformly in a high-speed mixer to obtain material IV, wherein the amount of lithium hydroxide substance=1.04*(the amount of manganese substance in slurry I+the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com