Contact thermal resistance testing system with variable pressure and temperature in profound hypothermia area

A contact thermal resistance and testing system technology, applied in the field of low-temperature heat exchange, can solve problems such as low operability and great influence on measurement accuracy, achieve high operability, reduce heat conduction heat leakage and radiation heat leakage, and shorten the experiment time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

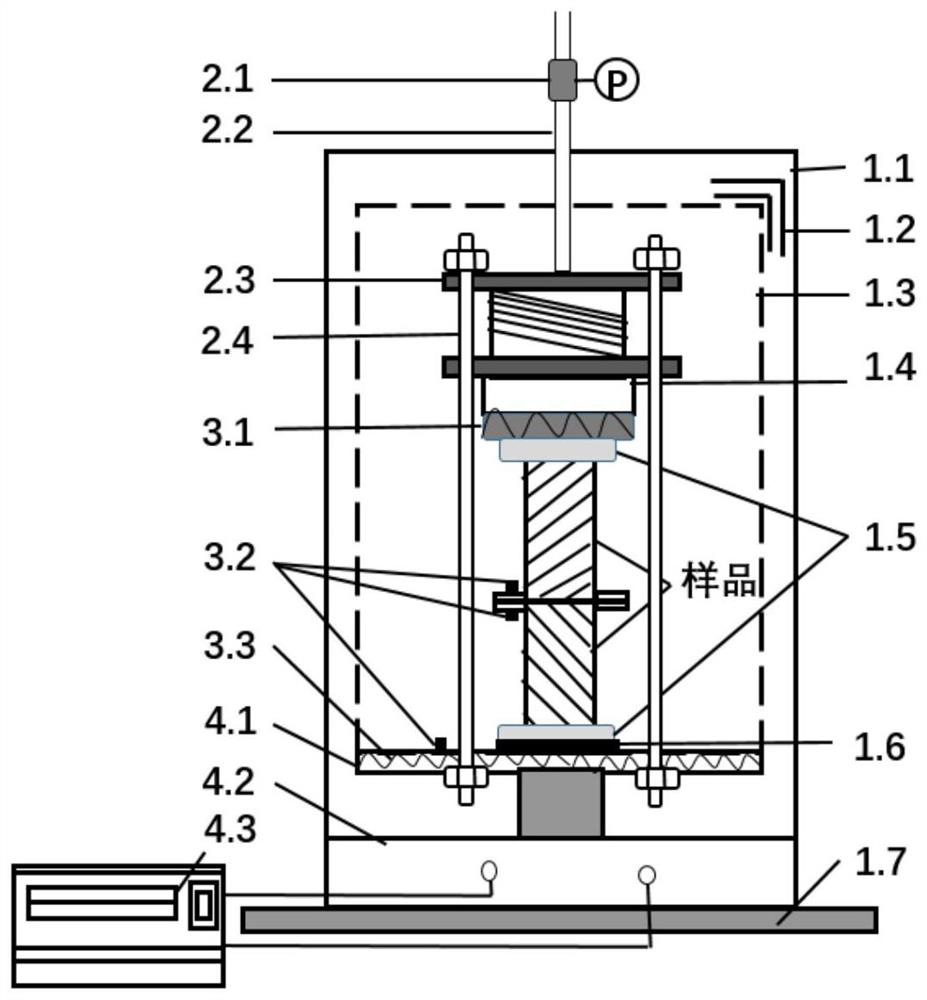

[0014] Such as figure 1 As shown, the present invention provides a thermal contact resistance testing system with variable pressure and temperature in the deep low temperature zone, and the high precision testing device is applied to the measurement of solid contact thermal resistance in the deep low temperature zone. The test device is placed in a vacuum chamber 1.1 as a whole, and a radiation-proof cold shield 1.3 is set and a heat-insulating multi-layer material 1.2 is wrapped outside the cold shield to effectively reduce the radiation heat leakage of the test sample when it is measured in a deep low temperature region. Among them, the vacuum chamber 1.1 is made of stainless steel with a thickness of 20mm; the heat-insulating multi-layer material 1.2 is composed of 10 layers of perforated double-sided aluminized film and 10 layers of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com