Composite membrane for acid-base water electrolysis as well as preparation method and application thereof

A composite membrane and water electrolysis technology, which is applied in the field of water electrolysis, can solve problems such as huge difference in molecular structure, large membrane resistance of bipolar membranes, and offset technical advantages, so as to improve battery performance and mechanical strength, reduce decomposition voltage, and avoid membrane The effect of large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

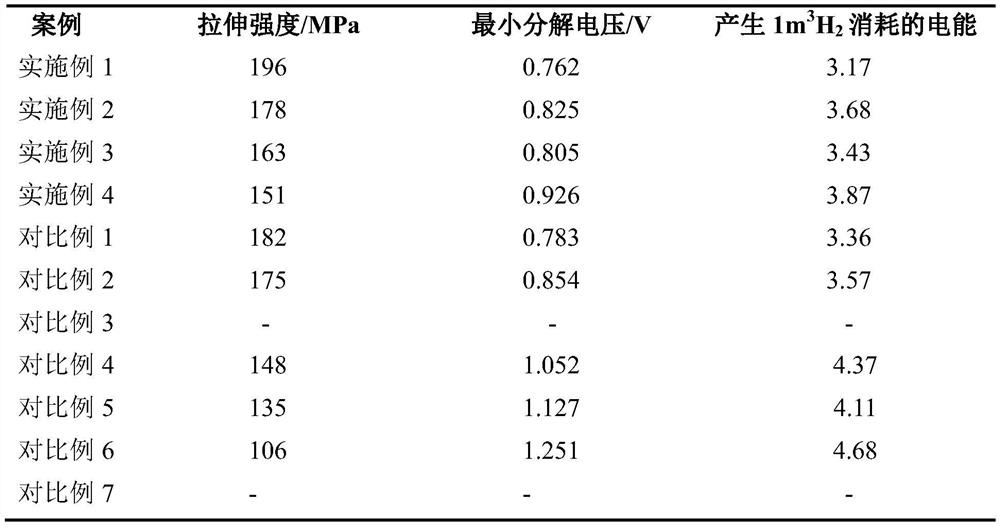

Examples

Embodiment 1

[0040] Step 1: Weigh 148g of polyphosphoric acid into a 250mL three-neck flask, put it in a 160°C oil bath, stir mechanically and pass in nitrogen protection, the nitrogen flow rate is 200mL / min, and continue heating for 40min. Then, 3.2465g of 3,3'-diaminobenzidine was added into the three-necked flask, mechanically stirred in an oil bath at 160°C for 3h, the length of the stirring blade was 15cm, and the stirring speed was 500r / min. Then the temperature was raised to 180°C, 2.5171g of isophthalic acid, 0.0547g of triphenyl phosphate and 4.52g of phosphorus pentoxide were sequentially added, and the temperature was raised to 220°C for 24 hours to obtain a polymer product. After the reaction, the product in the flask is quickly poured into deionized water, and the refined polybenzimidazole polymer is obtained through steps such as adding alkali to remove acid, drying, pulverizing, washing with water, and washing with ethanol.

[0041] Step 2: Dissolve 10g of dicyandiamide and ...

Embodiment 2

[0045] Step 1: Weigh 3.28g of 3,4-diaminobenzoic acid into a 100ml three-necked flask, measure 25ml of Eaton reagent into the three-necked flask, heat in an oil bath at 140°C, and mechanically stir at a rate of 300r / min. After 2 hours. The viscous synthetic product is quickly poured into deionized water, and the refined ABPBI polymer is obtained through steps such as adding alkali to remove acid, drying, crushing, washing with water, and washing with ethanol.

[0046] Step 2: Dissolve 10g of dicyandiamide and 5g of oxalic acid in 50g of deionized water, stir for 4 hours, then dry in vacuum at 80°C for 24 hours to obtain white crystals, grind them thoroughly and place them in a crucible, then calcinate them in a tube furnace. Heating from room temperature to 550°C with a heating rate of 5°C min -1 , air atmosphere, after heating up to the set temperature, keep it for 4 hours, cool down with the furnace, transfer it to a mortar and grind it into powder carefully, then wash it w...

Embodiment 3

[0051] Step 1: Weigh 168g of polyphosphoric acid and place it in a 250mL three-neck flask, put it in an oil bath at 160°C, stir mechanically and pass in nitrogen protection, the nitrogen flow rate is 200mL / min, and continue heating for 30min. Then, 3.2465g of 3,3'-diaminobenzidine was added into the three-necked flask, mechanically stirred in an oil bath at 160°C for 3h, the length of the stirring blade was 15cm, and the stirring speed was 500r / min. Then the temperature was raised to 180°C, 2.2427g of isophthalic acid, 0.2282g of 3,4-diaminobenzoic acid, 0.0412g of triphenyl phosphate and 4.324g of phosphorus pentoxide were added in sequence, and reacted at 200°C for 24 hours to obtain a polymer product. After the reaction, the product in the flask is quickly poured into deionized water, and the refined polybenzimidazole polymer is obtained through steps such as adding alkali to remove acid, drying, pulverizing, washing with water, and washing with ethanol.

[0052] Step 2: Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com