Method for improving safety and quality of red dates

A jujube quality technology, applied in food preservation, preservation of fruits/vegetables through radiation/electrical treatment, freshness of fruits and vegetables, etc., can solve the problem of damaged nutritional value of dried jujube, difficult treatment of chemical residual liquid, slow drying efficiency of hot air, etc. problem, to achieve the effect of simple process, short pretreatment time and improved time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

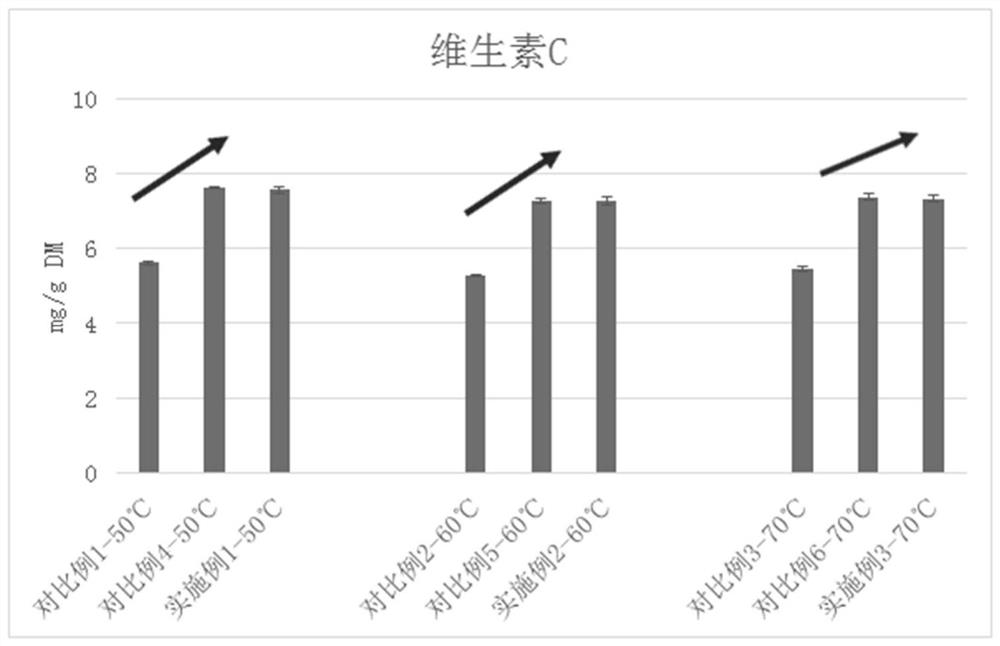

Embodiment 1

[0053]Place the fresh red dates in the container and keep the container in an ice water bath environment. Glow discharge cold plasma equipment (TS-HG20-1, Shenzhen Dongxin Hi-Tech Automation Equipment Co., Ltd.) is composed of electrodes and dielectrics. The copper cylinder is grounded as the cathode, and the metal rod made of tungsten alloy is connected to the high-voltage DC power supply as the anode. , The plasma zone is at the end of the inner anode. Adjust the cold plasma processing power to 600W, use air as the cold plasma source, the cold plasma flow rate is 150L / min, the cold plasma equipment is 5cm away from the jujube surface, the pretreatment time is 10s, and the face is turned once during the process. Preheat the temperature of the hot air dryer to 50℃, put the pre-treated red dates into hot air drying at a wind speed of 1.5m / s, and measure the water content of the red dates every 30 minutes. When the water content of the red dates is less than 35% (calculated on a wet b...

Embodiment 2

[0056]Place the fresh red dates in the container and keep the container in an ice water bath environment. Glow discharge cold plasma equipment (TS-HG20-1, Shenzhen Dongxin Hi-Tech Automation Equipment Co., Ltd.) is composed of electrodes and dielectrics. The copper cylinder is grounded as the cathode, and the metal rod made of tungsten alloy is connected to the high-voltage DC power supply as the anode. , The plasma zone is at the end of the inner anode. Adjust the cold plasma processing power to 800W, use air as the cold plasma source, the cold plasma flow rate is 50L / min, the cold plasma equipment is 8cm away from the red jujube surface, the pretreatment time is 60s, and the face is turned once during the process. Preheat the temperature of the hot air dryer to 60℃, put the pretreated red dates into hot air drying at a wind speed of 2.0m / s, and measure the water content of the red dates every 30 minutes. When the water content of the red dates is less than 35% (calculated on a wet...

Embodiment 3

[0059]Place the fresh red dates in the container and keep the container in an ice water bath environment. Glow discharge cold plasma equipment (TS-HG20-1, Shenzhen Dongxin Hi-Tech Automation Equipment Co., Ltd.) is composed of electrodes and dielectrics. The copper cylinder is grounded as the cathode, and the metal rod made of tungsten alloy is connected to the high-voltage DC power supply as the anode. , The plasma zone is at the end of the inner anode. Adjust the cold plasma processing power to 650W, use air as the cold plasma source, the cold plasma flow rate is 200L / min, the cold plasma equipment is 10cm away from the jujube surface, the pretreatment time is 30s, and the face is turned once during the process. Preheat the temperature of the hot air dryer to 70℃, put the pretreated red dates into hot air drying at a wind speed of 1.5m / s, and measure the water content of the red dates every 30 minutes. When the water content of the red dates is less than 35% (on a wet basis) ), st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com