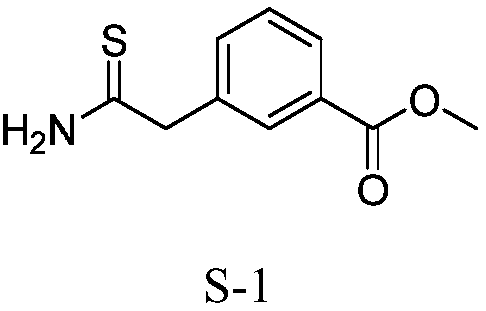

The preparation method of 3-(2-amino-2-thioethyl) methyl benzoate

A technology of methyl cyanomethyl benzoate and methyl benzoate, which is applied in the field of preparing methyl 3-benzoate, can solve the problems of large amount of waste water, high production cost, inability to recycle catalysts, etc., and achieve small amount of waste water, The effect of lower production cost and less catalyst consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

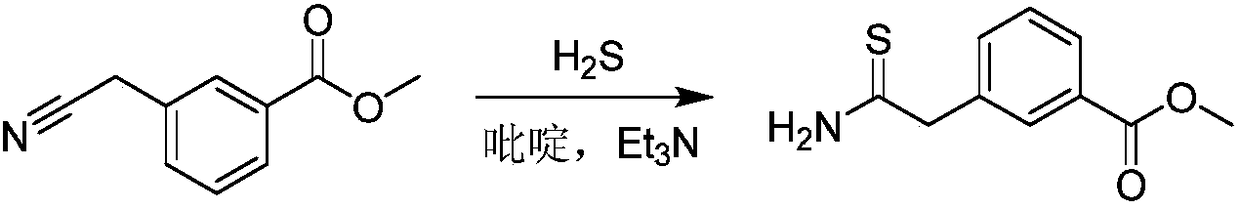

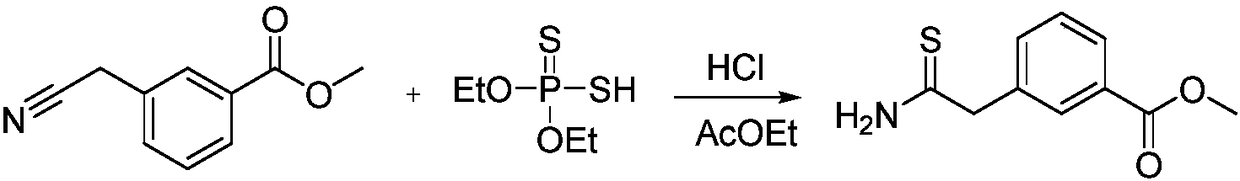

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, a kind of preparation method of 3-(2-amino-2-thioethyl) methyl benzoate, carries out following steps successively:

[0047] 1), in the 500ml autoclave with stirring and temperature control, add 3-cyanomethylbenzoic acid methyl ester 88.3g (99.2wt%, 0.5mol), water 130ml, acetamidine hydrochloride 4.4g (accounting for raw material 5wt%), also add about 3.7g of 70% (mass %) NaSH, thereby adjust the pH value to about 10; Pass into H 2 S gas until the reaction pressure is 0.5MPa, stir and raise the temperature to about 70°C, and stop the reaction after 4 hours of heat preservation reaction (at this time, the system pressure remains unchanged);

[0048] 2), after stopping the reaction, cool to room temperature, the H in the kettle 2 S gas is absorbed with concentrated lye (NaOH solution with a mass concentration of 50%), 5 wt% dilute hydrochloric acid is added dropwise to the kettle liquid to adjust the solution to pH=6-7, filtered, the filtrate is recycled, and ...

Embodiment 2

[0049] Embodiment 2, a kind of preparation method of 3-(2-amino-2-thioethyl) methyl benzoate, carry out following steps successively:

[0050] 1), add 88.3g (99.2wt%, 0.5mol) of methyl 3-cyanomethylbenzoate, water 150ml, acetamidine hydrochloride 2.6g (accounting for raw material) in the 500ml autoclave with stirring and temperature control 3wt%), also add about 2.2g of 70%NaSH, thereby adjust the pH value to about 9; Pass into H 2 S gas until the reaction pressure is 0.5MPa, stir and raise the temperature to about 75°C, and stop the reaction after 4.5h of heat preservation reaction (at this time, the system pressure remains unchanged);

[0051] 2), after stopping the reaction, cool to room temperature, the H in the kettle 2 S gas is absorbed with concentrated alkali solution, 5wt% dilute hydrochloric acid is added dropwise to the kettle liquid to adjust the solution to pH=6-7, filtered, the filtrate is recycled, the filter cake is washed with water (1×200ml), filtered, and d...

Embodiment 3

[0052] Embodiment 3, a kind of preparation method of 3-(2-amino-2-thioethyl) methyl benzoate, carries out following steps successively:

[0053] 1), in the 500ml autoclave with stirring and temperature control, add 3-cyanomethylbenzoic acid methyl ester 88.3g (99.2wt%, 0.5mol), water 150ml, propionamidine hydrochloride 3.5g (accounting for raw material 4wt%) also add about 2.6g of 70%NaSH, thereby adjust the pH value to about 9; Pass into H 2 S gas until the reaction pressure is 0.7MPa, stir and raise the temperature to about 85°C, and stop the reaction after holding the heat for 3 hours (the system pressure remains unchanged at this time);

[0054] 2), after stopping the reaction, cool to room temperature, the H in the kettle 2 S gas is absorbed with concentrated alkali solution, 5wt% dilute hydrochloric acid is added dropwise to the kettle liquid to adjust the solution to pH=6-7, filtered, the filtrate is recycled, the filter cake is washed with water (1×200ml), filtered, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com