Fish oil or algal oil loaded microcapsule as well as preparation method and application thereof

A technology of microcapsules and algae oil, which is applied in application, food forming, food science, etc., can solve the problems of difficult control of reaction conditions, difficult preparation of liposomes, and low product load, so as to avoid oxidation and diffusion, and adapt to the Effects on promotion and application, extensive promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

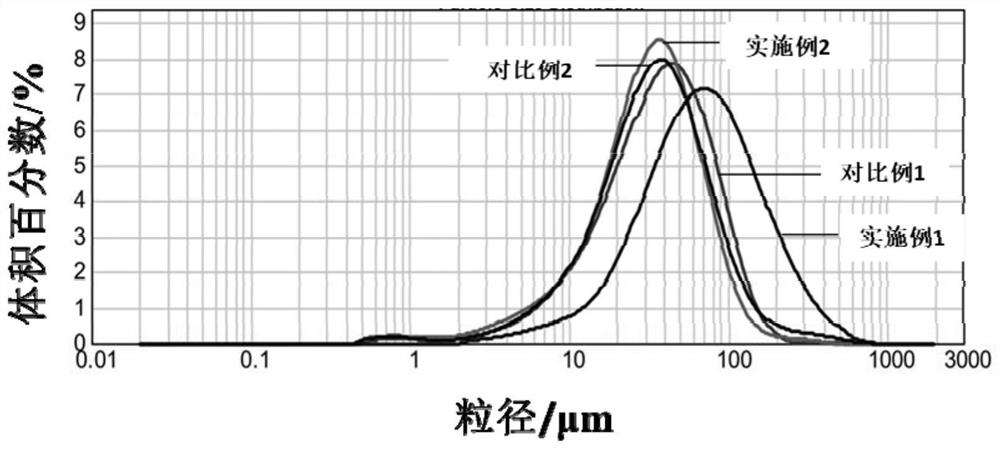

Embodiment 1

[0060] This embodiment provides a method for preparing microcapsules loaded with fish oil or algae oil, said preparation method comprising the following steps:

[0061] (1) Set the target mass ratio of sodium alginate, gelatin and glucose (protective agent) to 6:1:1, take 0.3g sodium alginate and dissolve it in 10mL deionized water, take 0.05g glucose and 0.05g gelatin and dissolve it in 10mL deionized water, mix the two evenly to obtain a wall material solution; wherein, the concentration of sodium alginate in the wall material solution is 1.5g / mL;

[0062] (2) According to the target oil loading of 30%, add 0.12g fish oil to the wall material solution described in step (1) and use ultrasonic emulsification treatment to mix evenly to obtain the wall core material mixed emulsion; wherein, the ultrasonic emulsification treatment The ultrasonic power is 200W, the ultrasonic program is super 2s and stop 2s, and the ultrasonic time is 1min;

[0063] (3) the wall core material mix...

Embodiment 2

[0066] This example provides a method for preparing microcapsules loaded with fish oil or algae oil, except that the "glucose" in step (1) is replaced with "sucrose", and the other conditions are exactly the same as in Example 1.

Embodiment 3

[0068] This example provides a method for preparing microcapsules loaded with fish oil or algae oil, except that the amount of fish oil added in step (2) is replaced by "0.12g" to "0.20g", that is, the target oil load is changed from "30% " is replaced by " 50% ", and other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com