Silicon fine particles and method for producing same

A manufacturing method and technology of silicon particles, applied in chemical instruments and methods, silicon, silicon compounds, etc., can solve the problems of less damage/deformation, oxidation resistance, difficult continuous production, clogging of reaction tubes, etc., and achieve less irreversible reactions. Destructive, long-term stable performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

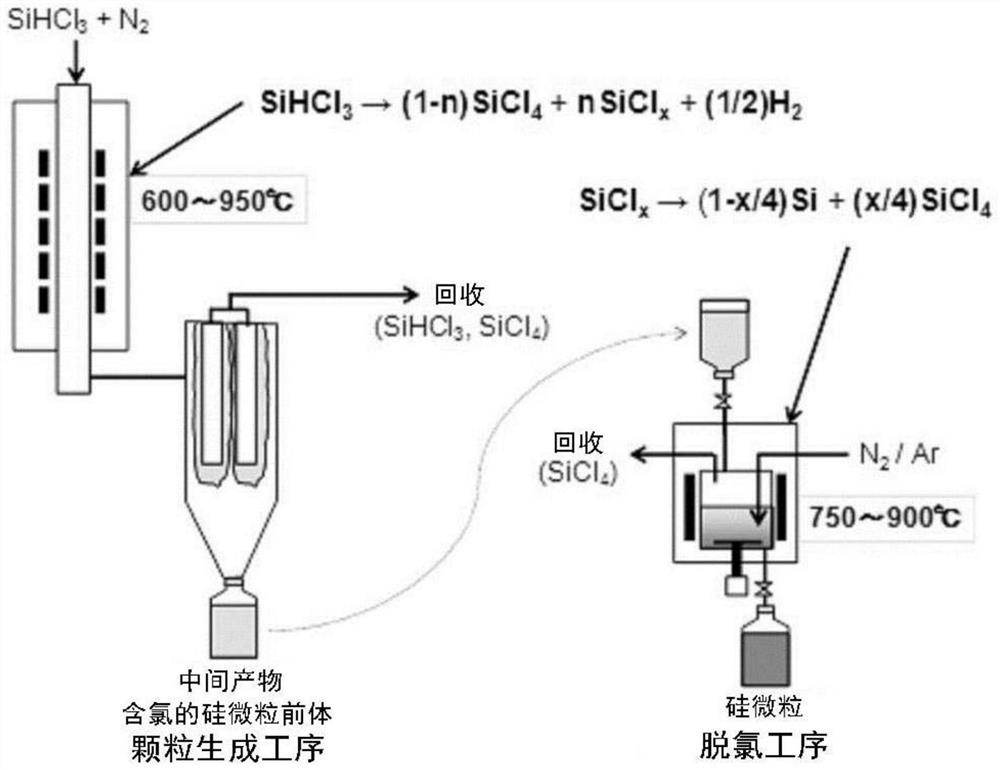

[0110] Synthesis of chlorine-containing silicon particle precursors

[0111] A graphite reaction cylinder with an inner diameter of 80 mm and a length of 2500 mm was heated to 750° C., and a silicon microparticle precursor was synthesized by feeding trichlorosilane at a rate of 900 g / min and entraining nitrogen at a rate of 37 NL (L is liter) / min. Baghouses separate / trap unreacted gases. The reaction rate of trichlorosilane was about 40%, and the baghouse captured about 70% of the resulting silicon particle precursors. The collected silicon fine particle precursor was stored in a storage container whose atmosphere was replaced with nitrogen.

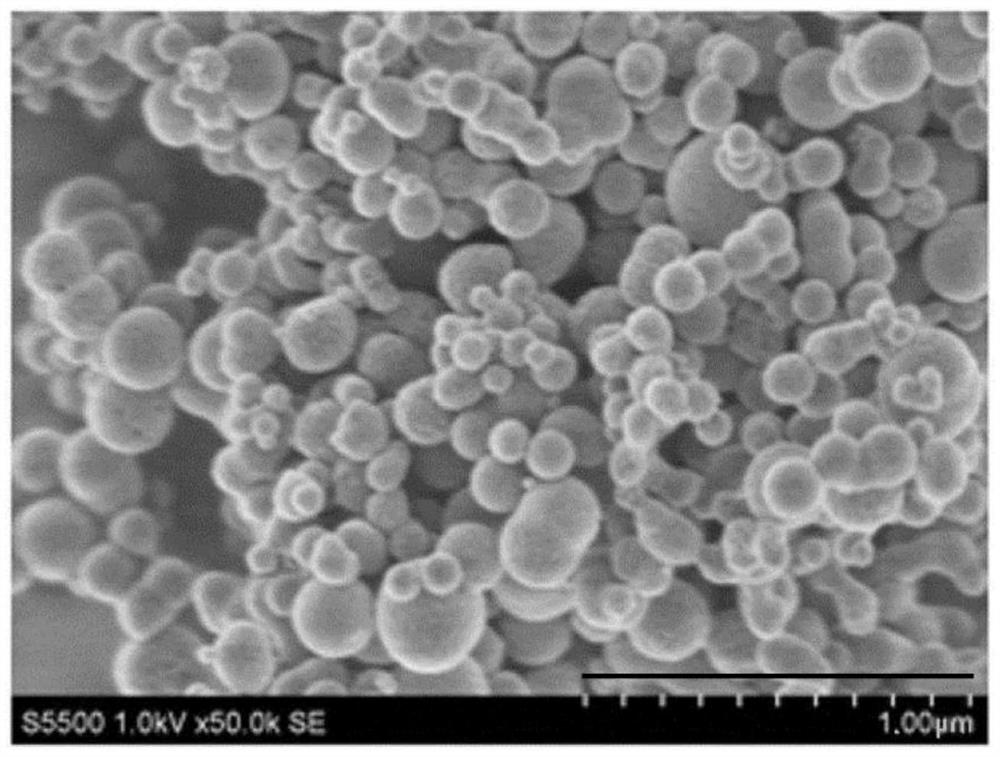

[0112] When a part of the captured silicon microparticle precursor is released to the atmosphere, it reacts with moisture in the air to generate white smoke of hydrogen chloride and oxidizes it. Analysis of the silicon fine particle precursor after the atmosphere was released revealed that the oxygen concentration was 15.2%. The speci...

Embodiment 2

[0117] In Example 1, the silicon fine particle precursor was obtained under the same conditions except that the temperature of the reaction cylinder when synthesizing the silicon fine particle precursor was set at 850°C.

[0118] The obtained silicon fine particle precursor was dechlorinated under the same dechlorination conditions as in Example 1. As a result, the oxygen concentration (C o ) is 0.6% by mass, the chlorine concentration is 4.7% by mass, and the specific surface area (S) is 20m 2 / g. The ratio of oxygen concentration to specific surface area (C o / S) becomes 0.030. In addition, the average particle diameter was 129 nm, and the crystallite diameter was 8 nm.

Embodiment 3

[0120] In Example 1, the silicon fine particle precursor was obtained under the same conditions except that the temperature of the reaction cylinder during the synthesis of the silicon fine particle precursor was set at 700°C. The obtained silicon fine particle precursor was dechlorinated under the same dechlorination conditions as in Examples. As a result, the oxygen concentration (C o ) is 0.8% by mass, the chlorine concentration is 4.8% by mass, and the specific surface area (S) is 22m 2 / g. The ratio of oxygen concentration to specific surface area (C o / S) becomes 0.036. In addition, the average particle diameter was 117 nm, and the crystallite diameter was 7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com