Graphene-like coated iron-based compound doped cathode material and preparation method thereof

A graphene-coated, negative-electrode material technology, applied to battery electrodes, electrical components, circuits, etc., can solve the problems of cumbersome operation, poor electrochemical performance, and difficult to control product components, and achieve simple operation, low cost, and reduced The effect of an irreversible reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

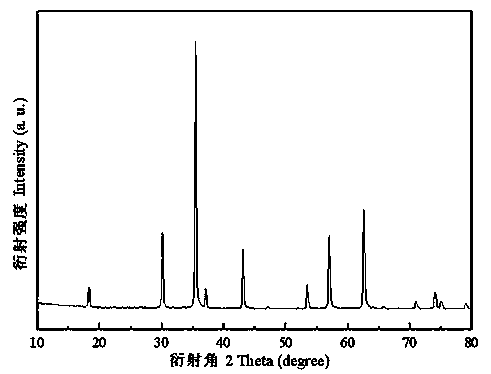

[0044] (1) Weigh 1 g of self-made iron oxide Fe with a particle size of 16 nm 3-x o 4 The powder was ground and mixed with 0.05 g of acrylonitrile oligomer, and cured at a constant temperature at 220 °C for 2 hours in an air atmosphere to obtain a precursor.

[0045] (2) The precursor obtained in step (1) was ball-milled for 24 hours in a planetary ball mill with a ball-to-material ratio of 10 : 1, 400 r / min, and then calcined at 300 °C for 1 hour under the protection of nitrogen, and then continued Sintering at 500°C for 8 hours, the acrylonitrile oligomer is sintered to form a graphene-like coating layer on the surface of the particles. Since less acrylonitrile oligomer is added, the sintering time is shorter, and the oxide is not reduced to iron. to produce Fe 3-x o 4 / C composite powder.

Embodiment 2

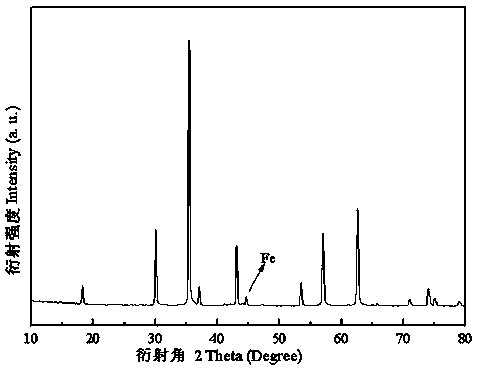

[0047] (1) Weigh 1 g of iron oxide Fe with a particle size of 20 nm 3-x o 4 The powder was ground and mixed with 0.12 g of acrylonitrile oligomer, and cured at a constant temperature at 180 °C for 4 hours in an air atmosphere to obtain a precursor.

[0048] (2) The precursor obtained in step (1) was ball-milled for 24 hours in a planetary ball mill with a ball-to-material ratio of 10 : 1, 400 r / min, and then calcined at 300 °C for 1 hour under the protection of nitrogen, and then continued The temperature was raised to 600 °C for 6 hours, and the acrylonitrile oligomer was sintered to form a graphene-like coating layer on the particle surface, and a small amount of Fe 3-x o 4 reduced to simple substance α -Fe, get Fe 3-x o 4 / Fe / C composite powder.

Embodiment 3

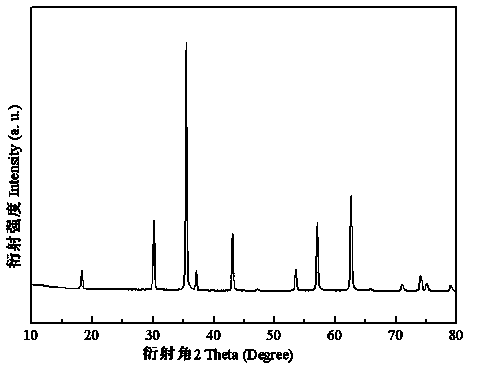

[0050] (1) Weigh commercially available iron oxide with a particle size of 250 nm α -Fe 2 o 3 2 g of powder and 0.4 g of acrylonitrile oligomer were ground and mixed evenly, and cured at a constant temperature for 4 hours at 180 °C in an air atmosphere to obtain a precursor.

[0051] (2) The precursor obtained in step (1) was ball milled in a planetary ball mill with a ball-to-material ratio of 10 : 1, 400 r / min for 24 hours, then calcined at 300 °C for 1 hour under the protection of argon, and then Continue to heat up to 700 ° C for 2 hours, the acrylonitrile oligomer is sintered to form a graphene-like coating on the surface of the particle, and α -Fe 2 o 3 All reduced to Fe 3-x o 4 , get Fe 3-x o 4 / C composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com