Method for improving lithium negative electrode performance

A lithium anode and performance technology, applied in the field of preparation of lithium anode, can solve problems such as battery short circuit, safety problems, restricting lithium-sulfur batteries, etc., and achieve the effects of inhibiting the generation of lithium dendrites, reducing irreversible reactions, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

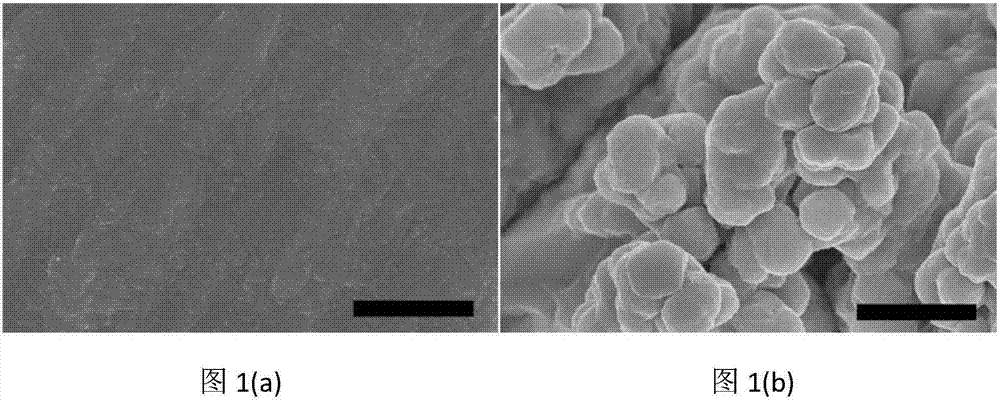

[0028] The first step is to clean the copper foil current collector.

[0029] The quality copper foil was immersed in deionized water, ethanol and acetone in the ratio (v:v, 1:1:1) of the mixed solution prepared at room temperature, then ultrasonically treated for 30min, and finally taken out and dried at 80°C for 1h.

[0030] In the second step, Au is plated on one side of the copper foil.

[0031] Put the cleaned copper foil current collector into an ion sputtering / evaporation integrated coating device, and sputter and evaporate for 90s to obtain a gold-plated Au@Cu electrode on one side.

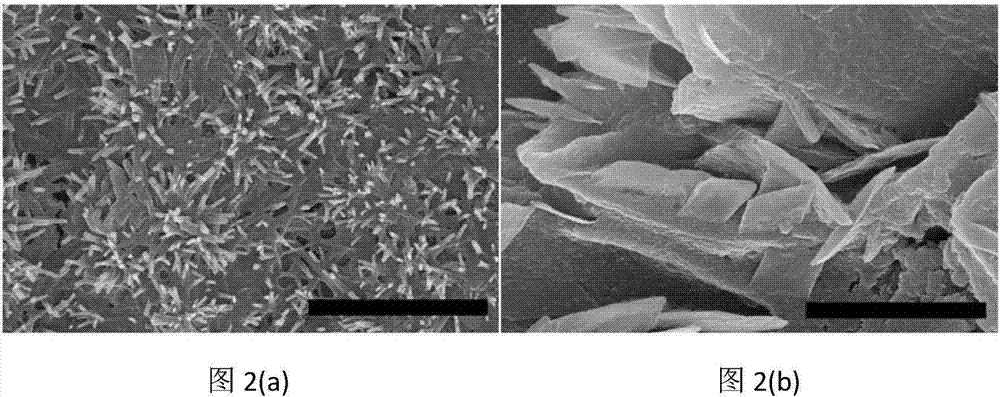

[0032] The third step is to assemble the battery.

[0033] The prepared single-sided gold-plated Au@Cu electrode was used as the working electrode, and the lithium sheet was used as the counter electrode to form a button battery. The separator was made of polypropylene film, and the gold-plated side was placed on the opposite side of the separator. The electrolyte is selected to contain...

Embodiment example 2

[0041] The first step, copper foil current collector cleaning

[0042] The quality copper foil was immersed in deionized water, ethanol and acetone in the ratio (v:v, 1:1:1) of the mixed solution prepared at room temperature, then ultrasonically treated for 20min, and finally taken out and dried at 70°C for 2h.

[0043] The second step is to plate gold on one side of the copper foil

[0044] Put the cleaned copper foil current collector into an ion sputtering / evaporation integrated coating device, and sputter and evaporate for 60s to obtain a gold-plated Au@Cu electrode on one side.

[0045] The third step is to assemble the battery.

[0046] The prepared single-sided gold-plated Au@Cu electrode was used as the working electrode, and the lithium sheet was used as the counter electrode to form a button battery. The separator was made of polypropylene film, and the gold-plated side was placed on the opposite side of the separator. The electrolyte is selected to contain 1M lith...

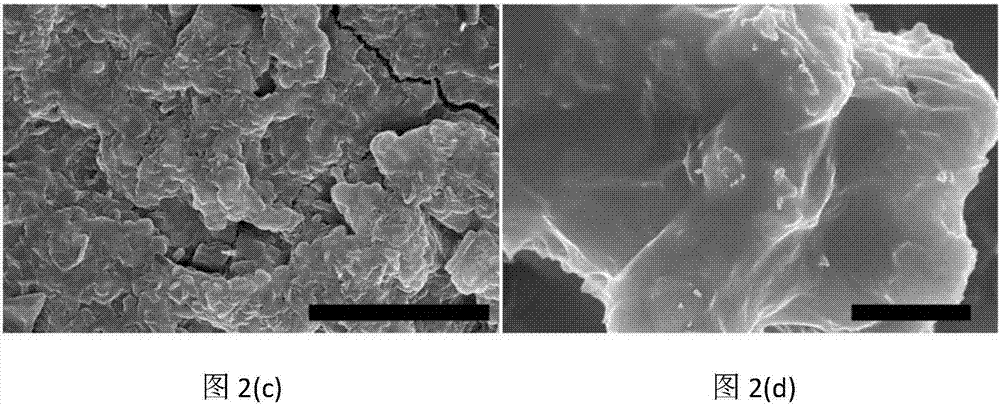

Embodiment example 3

[0048] The first step is to clean the copper foil current collector.

[0049] The quality copper foil was immersed in deionized water, ethanol and acetone in the ratio (v:v, 1:1:1) of the mixed solution prepared at room temperature, then ultrasonically treated for 15min, and finally taken out and dried at 60°C for 3h.

[0050] In the second step, Au is plated on one side of the copper foil.

[0051] Put the cleaned copper foil current collector into an ion sputtering / evaporation integrated coating device, and sputter and evaporate for 30s to obtain a gold-plated Au@Cu electrode on one side.

[0052] The third step is to assemble the battery.

[0053] The prepared single-sided gold-plated Au@Cu electrode was used as the working electrode, and the lithium sheet was used as the counter electrode to form a button battery. The separator was made of polypropylene film, and the gold-plated side was placed on the opposite side of the separator. The electrolyte contains 1M lithium hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com