Negative plate with sandwich structure and lithium ion battery comprising negative plate

A negative electrode, negative electrode technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problem of inability to take into account the safety of overcharge and furnace temperature, poor safety of acupuncture and furnace temperature, and the impact of battery cycle life, etc. problems, to avoid short circuits in large areas, improve overcharge performance, and improve the safety of acupuncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of negative electrode sheet

[0049] Mix and disperse 96g lithium titanate powder, 2g binder PVDF, and 2g conductive carbon black in NMP to obtain lithium titanate slurry, wherein the particle size of lithium titanate is D 50 0.8μm;

[0050] Mix and disperse 95g graphite, 2g binder styrene-butadiene rubber, 1.5g dispersant sodium carboxymethyl cellulose and 1.5g conductive carbon black in deionized water to obtain graphite slurry, wherein the graphite particle size is D 50 10μm;

[0051] Disperse 95g of silicon oxide, 4g of binder styrene-butadiene rubber, and 1g of dispersant sodium carboxymethylcellulose in deionized water to obtain a silicon material slurry, wherein the particle size of the silicon material is D 50 1.0 μm;

[0052] Apply the lithium titanate slurry evenly on both sides of the copper foil, and dry at 80-120°C for 30-60 minutes to obtain a lithium titanate layer with a thickness of 5 μm; then apply the graphite slurry evenly on the t...

Embodiment 2-19

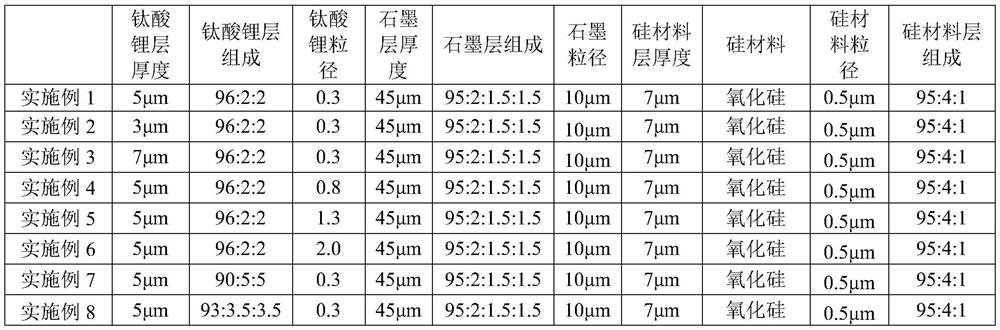

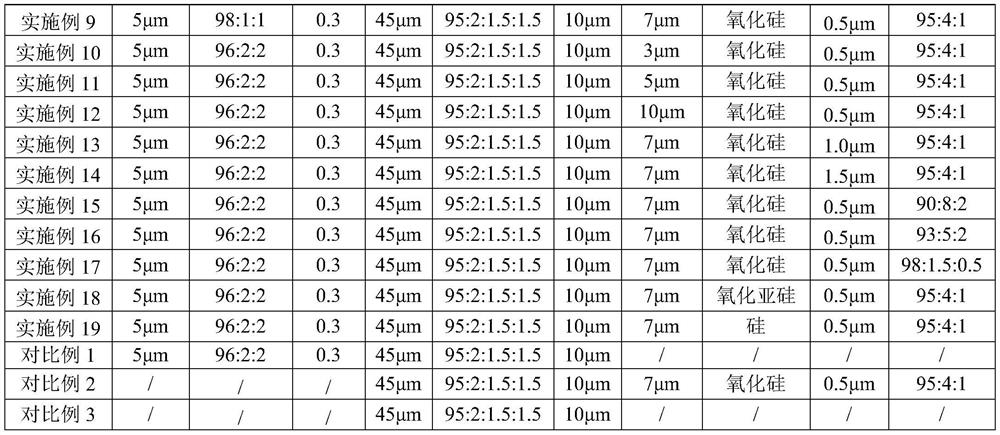

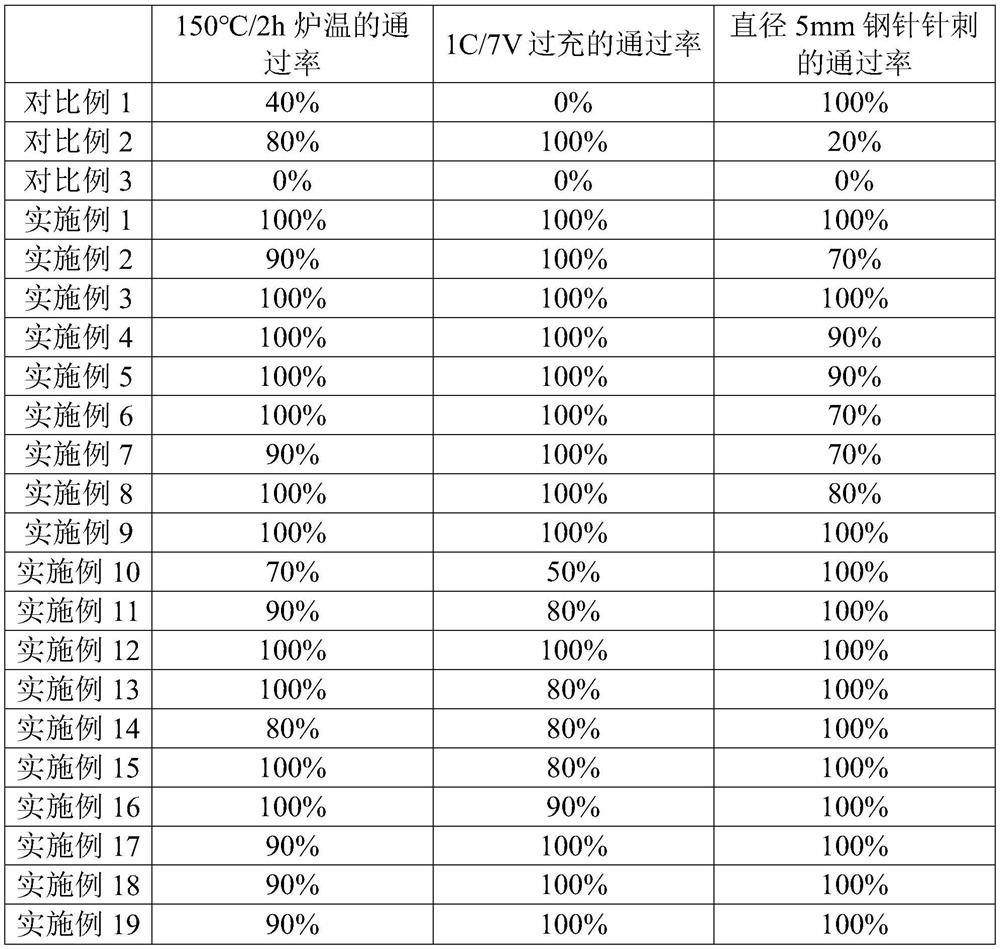

[0058] Examples 2-19 were prepared in the same manner as the lithium ion battery of Example 1, except that the thickness of each coating was different, and the composition of each component in each coating was different, as shown in Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com