Laminated battery preparation method capable of improving needling safety performance

A safety performance, lamination technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of uncontrollable cycle or rate performance, battery capacity reduction, cost increase, etc., to achieve significant production practical significance, reduce The effect of generating heat and improving the safety performance of acupuncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

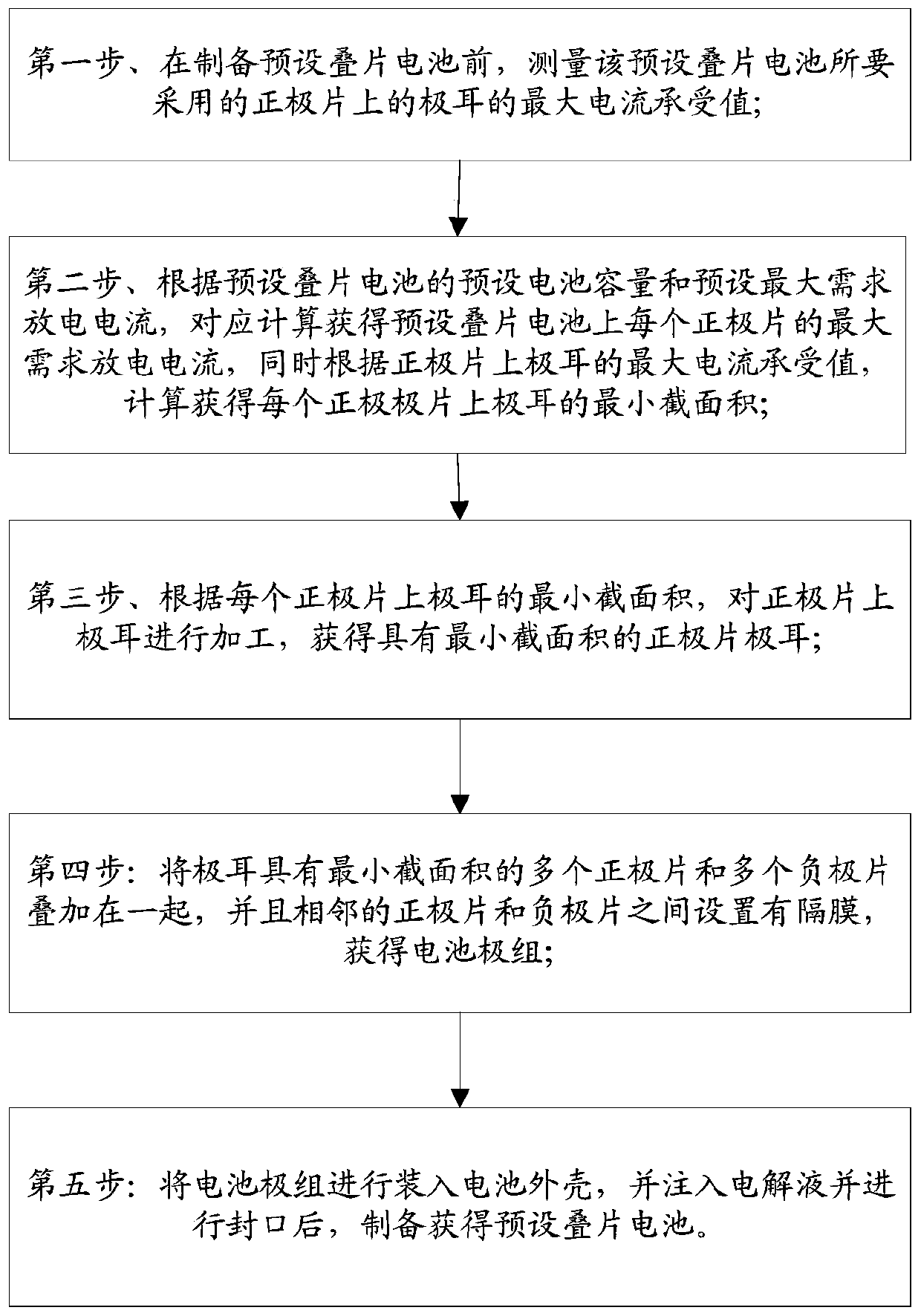

[0027] see figure 1 , the invention provides a method for preparing a laminated battery capable of improving acupuncture safety performance, the method comprising the following steps:

[0028] The first step: Before preparing the preset laminated battery, measure the maximum current withstand value of the tab on the positive electrode sheet to be used for the preset laminated battery. The preset laminated battery for the pre-equipment is: the user wants to obtain , a laminated battery with a preset battery capacity and a preset maximum required discharge current; the maximum current withstand value of the tab on the positive plate to be used in the preset laminated battery is the power-on of the tab on the positive plate when a power failure occurs Current size;

[0029] In terms of specific implementation, the preset laminated battery can be any kind of laminated battery that the user wants to obtain, has a preset battery capacity and a preset maximum required discharge curr...

Embodiment 1

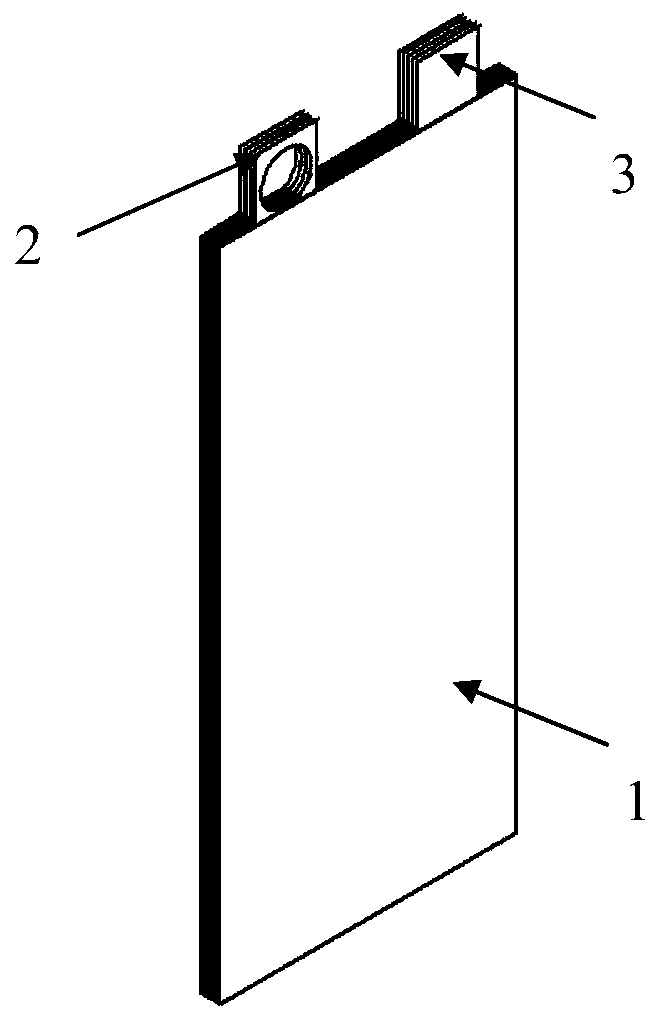

[0054] In Example 1, using a method for preparing a stacked battery that can improve the safety performance of needle punching provided by the present invention, the model 4360143 battery of the ternary material NCM622 stack is processed, and the detailed steps are as follows:

[0055] In the first step, since the positive electrode of the battery uses a current collector of 15 μm aluminum foil with a grade of 8021, two aluminum lugs with a width of 2mm are made out of the coated positive electrode, and the single electrode is made into a 4360143 similar battery. With the same weight of electrolyte, two positive tabs are drawn on the single pole piece battery. Use the charging and discharging equipment to charge the simulated battery with a gradient of 0.5A and increase the current. The initial current is 1A. When the current is 10.5A, the battery will be powered off and cannot continue to charge. Repeat three times, and the current is all within 10.5±0.5A, so it is determined...

Embodiment 2

[0061] In Example 2, using a method for preparing a stacked battery that can improve the safety performance of acupuncture provided by the present invention, the model of the ternary material NCM811 stacked battery is 4360143, and the detailed steps are as follows:

[0062] In the first step, since the positive electrode of the battery uses a current collector of 15 μm aluminum foil with a grade of 8021, two aluminum lugs with a width of 2mm are made out of the coated positive electrode, and the single electrode is made into a 4360143 similar battery. With the same weight of electrolyte, two positive tabs are drawn out on the single pole piece battery. Use the charging and discharging equipment to charge the simulated battery with a gradient of 0.5A and increase the current. The initial current is 1A. When the current is 10.5A, the battery will be powered off and cannot continue to charge. Repeat three times, and the current is all within 10.5±0.5A, so it is determined that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com