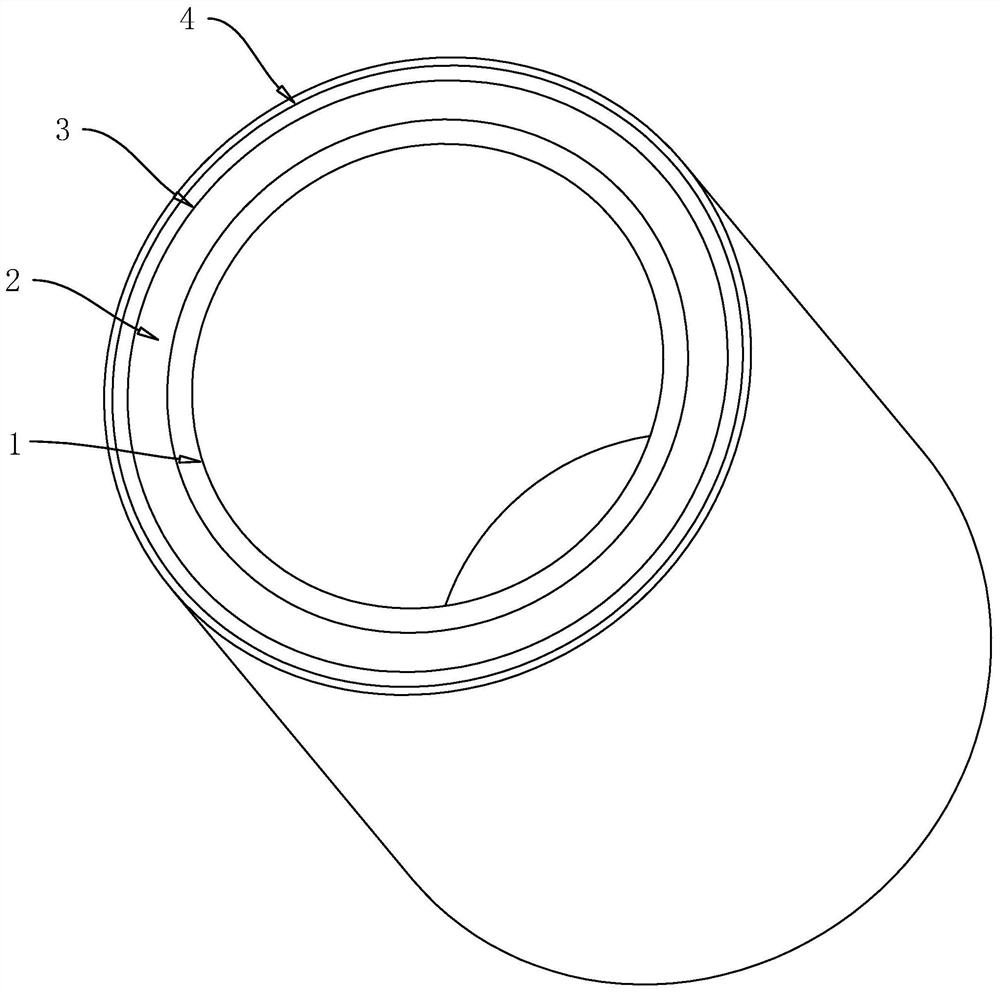

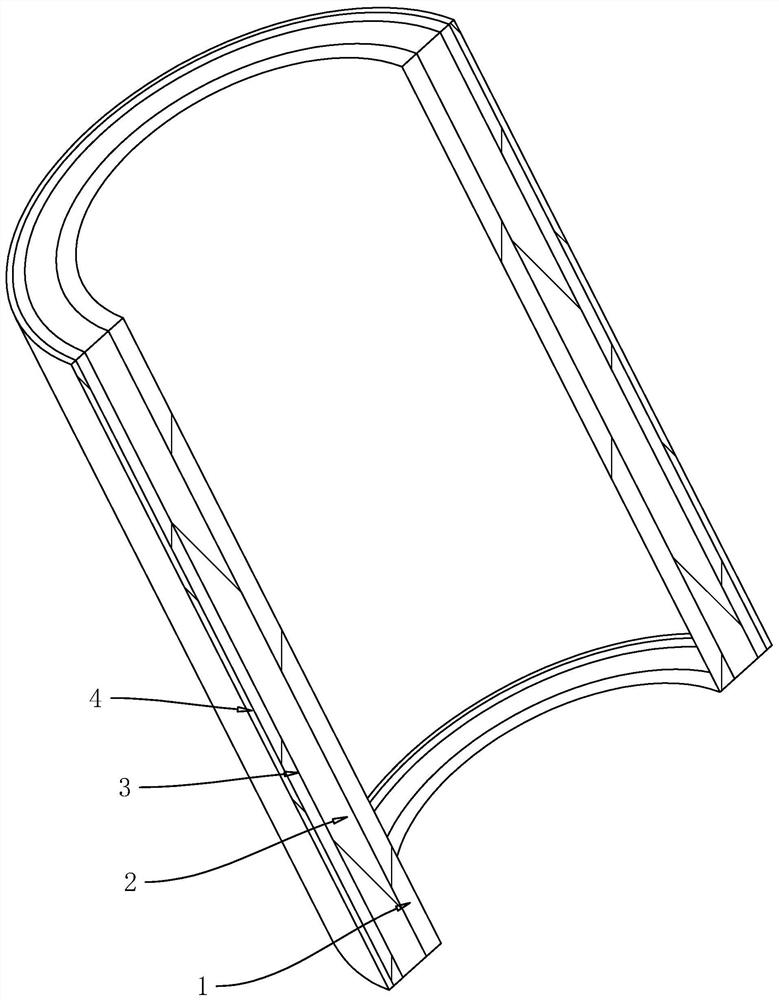

High corrosion resistance prefabricated overhead insulation pipe and preparation method thereof

A heat preservation pipe and corrosion-resistant technology, which is applied in the direction of heat preservation, pipe protection through heat insulation, pipe anti-corrosion/rust protection, etc., can solve the problems of accelerated corrosion of working steel pipes, and achieve improved corrosion resistance, compact texture, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

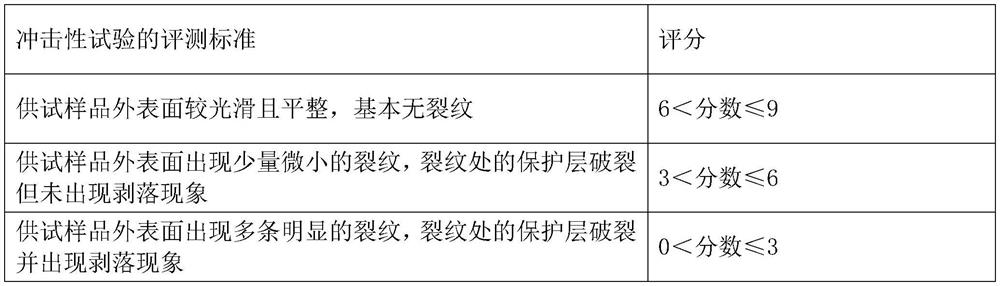

Examples

preparation example Construction

[0066] Preparation example of seaweed extract

[0067] The beater in each preparation example of seaweed extract is the beater provided by Jingjiang Zhongde Machinery Manufacturing Factory, the model is DJ2-001; the ball mill is the ball mill provided by Chuangfulai, the model is air-cooled XQM-4L, and the output particle size is 0.00001 mm (10nm); seaweed is commercial seaweed.

[0068] (1) Take a certain amount of seaweed to soak and clean until the surface is free of mucus;

[0069] (2) adding deionized water to the seaweed treated in (1), so that the volume ratio of feed water reaches 1:5, and then beating in a beater to make a slurry;

[0070] (3) After the slurry obtained in (2) is left to stand for 30min, carry out solid-liquid separation through filtration, and get the upper layer liquid;

[0071] (4) Take the upper layer liquid in (3) and dry it for 2 hours at a temperature of 65° C. to obtain a dry powder;

[0072] (5) Put the dry powder in (4) through wet ball mi...

preparation example 1

[0076] S1. Weigh 0.2kg of zinc sulfate, 100kg of 1mol / L hydrochloric acid solution, 4kg of tetraethyl orthosilicate, 2kg of polyethylene oxide polypropylene oxide monobutyl ether, and 6 kg of corrosion inhibitor;

[0077] S2. Add the zinc sulfate weighed in S1 into a 1mol / L hydrochloric acid solution, and stir for 20 minutes at a constant temperature of 40°C and a stirring rate of 1000r / min to obtain a solution A;

[0078] S3. Add polyethylene oxide polypropylene oxide monobutyl ether to the solution A obtained in S2, and stir for 50 min at a constant temperature of 40° C. and a stirring rate of 1000 r / min to obtain a solution B;

[0079] S4. Add tetraethyl orthosilicate to the solution B obtained in S3, and stir for 200 minutes at a constant temperature of 40° C. and a stirring rate of 1000 r / min to obtain a solution C;

[0080] S5, the solution C obtained in S4 was left to stand at room temperature for 24 hours, and then filtered at room temperature, and the precipitate in t...

preparation example 2

[0087] S1. Weigh 0.4kg of zinc sulfate, 150kg of 1mol / L hydrochloric acid solution, 6kg of tetraethyl orthosilicate, 3kg of polyethylene oxide polypropylene oxide monobutyl ether, and 7kg of corrosion inhibitor;

[0088] S2. Add the zinc sulfate weighed in S1 into a 1mol / L hydrochloric acid solution, and stir for 25 minutes at a constant temperature of 40°C and a stirring rate of 1000r / min to obtain a solution A;

[0089] S3. Add polyethylene oxide polypropylene oxide monobutyl ether to the solution A obtained in S2, and stir for 60 min at a constant temperature of 40° C. and a stirring rate of 1000 r / min to obtain a solution B;

[0090] S4. Add tetraethyl orthosilicate to the solution B obtained in S3, and stir for 220 minutes at a constant temperature of 40° C. and a stirring rate of 1000 r / min to obtain a solution C;

[0091] S5. The solution C obtained in S4 was left to stand at room temperature for 24 hours, and then filtered at room temperature;

[0092] S6. Take the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com