Efficient nitrogen recovery device and process for sewage

A recovery device and high-efficiency technology, applied in the field of high-efficiency nitrogen recovery devices for sewage, can solve the problems of excessive effluent quality, low concentration, and difficulty in reusing regenerated liquid, and achieve the effect of improving regeneration rate and regeneration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

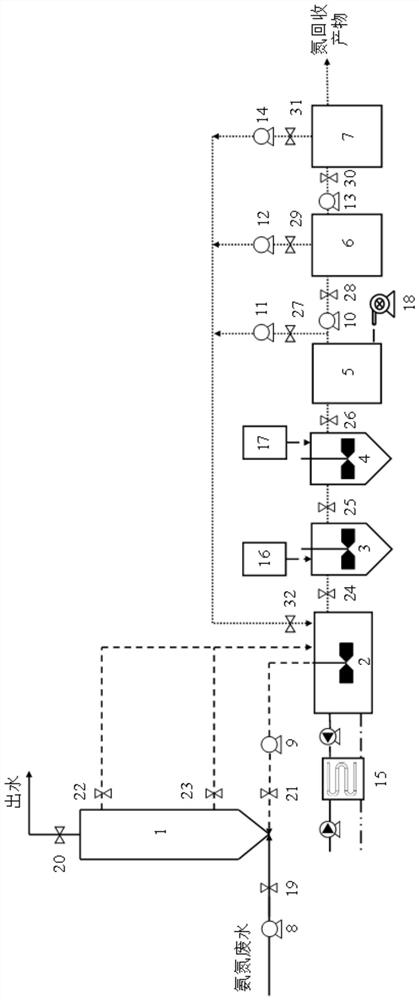

[0117] This example proposes a high-efficiency nitrogen recovery technology based on the mainstream ammonia nitrogen ion exchange-regeneration-side flow biological nitrification-electrodialysis concentration-evaporation crystallization process, that is, the CAIRB process. The process flow is as follows figure 1 As shown, it includes ammonia nitrogen ion exchange, regeneration, hardness ion removal, biological nitrification, electrodialysis concentration and evaporation crystallization unit. The ammonia nitrogen ion exchange unit includes a sewage water inlet pump 8 , a sewage water inlet valve 19 , an ammonia nitrogen ion exchange column 1 filled with ion exchangers, and a drain valve 20 connected in sequence. The regeneration unit includes a regeneration liquid storage tank 2 connected in sequence, a regeneration liquid inlet pump 9 and a regeneration liquid inlet valve 21, the regeneration liquid storage tank 2 is filled with regeneration liquid, the regeneration liquid stor...

Embodiment 2

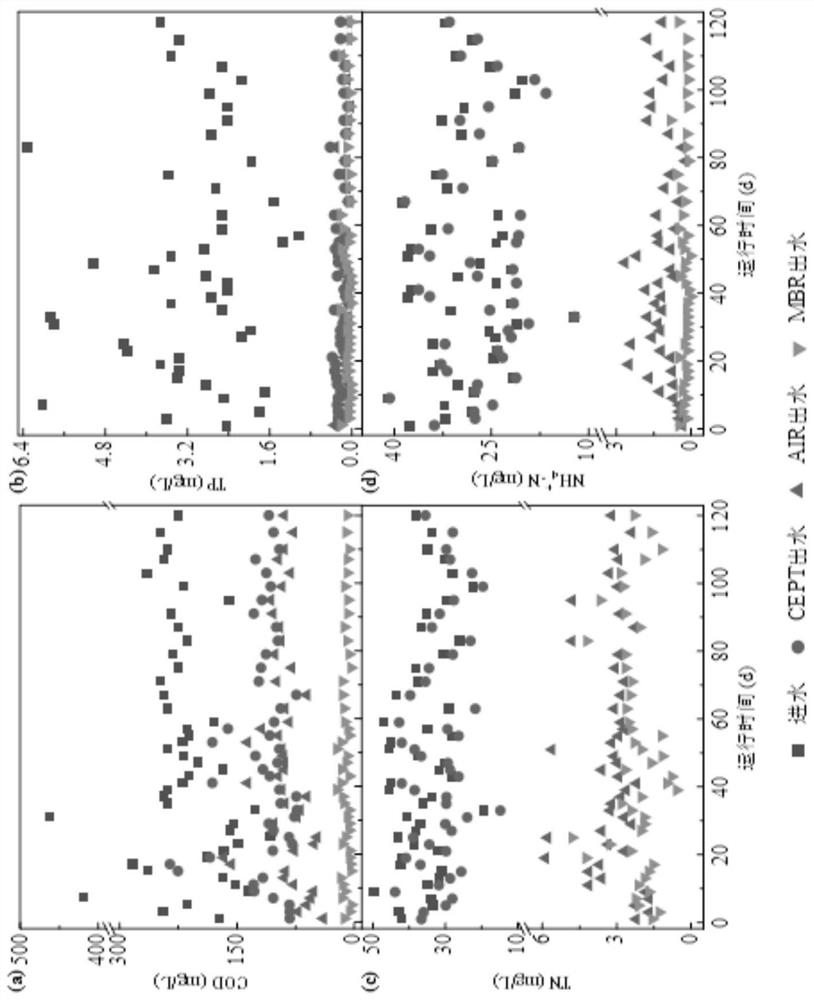

[0121] Influent COD, TN, NH of a sewage treatment plant 4 + -N, TP concentrations are 244.7, 27.3, 23.9, 3.0mg / L respectively, after treatment, they need to meet the requirements of GB18918-2002 Grade A standard (COD4 + -N<5mg / L, TP<0.5mg / L). The CAIRB process of Example 1 was used to carry out the pilot test research, the treated water volume was 2 tons / day, and the duration was 120 days.

[0122]The coagulant and flocculant used in CEPT are aluminum sulfate and anionic polyacrylamide (PAM), with dosages of 30 and 0.3 mg / L, respectively. The coagulation stirring speed was 200r / min, and the HRTs of the coagulation, flocculation and precipitation stages were 2, 8 and 30min, respectively. The CEPT effluent enters the ammonia nitrogen ion exchange column 1 from the sewage inlet pump 8 through the inlet valve 19. The ammonia nitrogen ion exchange column 1 has a volume of 5L and is filled with natural zeolite. The EBCT is 30min, the adsorption operation time is 20h, the water v...

Embodiment 3

[0129] for NH 4 + - A black and odorous water body with a N concentration of 15mg / L needs to be treated to meet the requirements of the IV water standard (1.5mg / L) in GB3838-2002. Using the CAIRB process for pilot study (refer to attached figure 2 ), the biological treatment unit uses BAF. The amount of water treated in the pilot plant is 1.0 tons per day, and the duration is 30 days.

[0130] This example is roughly the same as Example 2, and polyaluminum ferric sulfate (20 mg / L) and anion PAM (0.3 mg / L) are selected as coagulation and flocculants. The black and odorous water is first treated by coagulation and sedimentation, and then pumped into the AIR unit. The ammonia nitrogen ion exchange agent in the ammonia nitrogen ion exchange column 1 is a cationic resin, and 5 sets of ammonia nitrogen ion exchange columns are used to operate in parallel, 2 sets are reserved, and the EBCT control is 15 minutes. AIR unit effluent is pumped into BAF (HRT=2h) to further remove org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com