Series of pure-phase ordered palladium-boron intermetallic compounds, preparation method and application thereof

An intermetallic compound, a series of technologies, applied in the field of preparation, palladium boron intermetallic compound, high-efficiency electrocatalytic water splitting for hydrogen production, which can solve the problems of difficult to accurately obtain the precise position of atoms, disordered arrangement, and harsh conditions. , to achieve the effect of good synthesis repeatability, simple synthesis steps and high sample purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

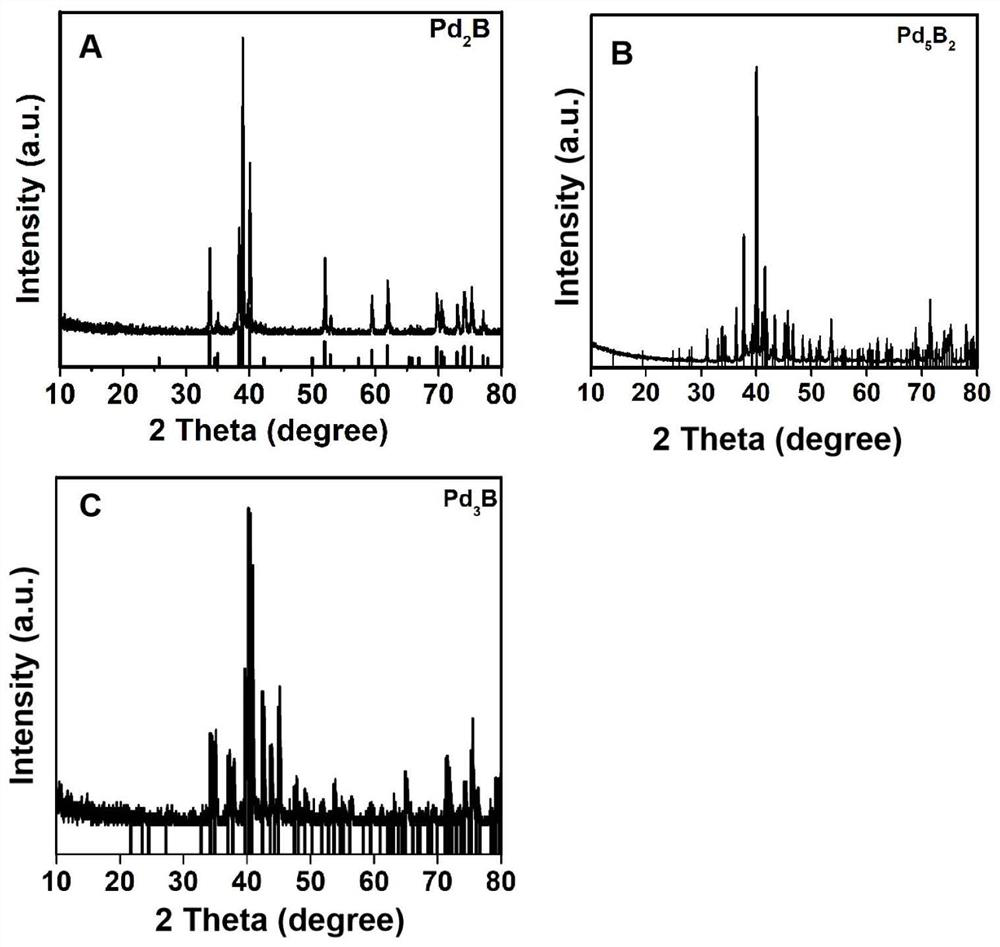

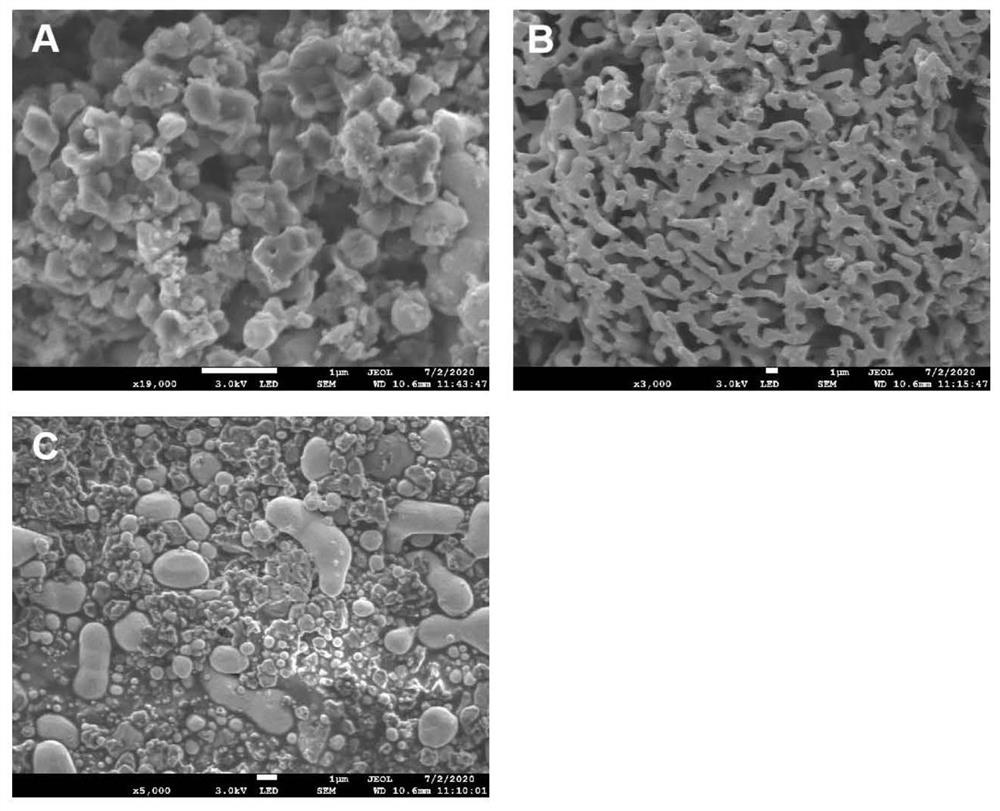

[0022]Pd2B. Preparation of intermetallic compound: Firstly, 73.55 mg of sodium tetrachloropalladate and 11.48 mg of magnesium diboride (molar ratio 1:1) were ground at room temperature to a homogeneous mixture, which was a black solid powder. Transfer the above black powder to the quartz tube. Connect the quartz tube filled with black powder to the vacuum device, use the vacuum device to reduce the vacuum in the quartz tube to below 1 Pa, and then place the sealed quartz tube in the muffle furnace and heat it to a temperature of 3°C / min Pd prepared by calcining at 500℃ for 2 hours2B. Or put the sealed quartz tube in a muffle furnace and heat it to 500°C at a heating rate of 3°C / min for 1 hour to prepare Pd5B2. Or put the sealed quartz tube in a muffle furnace and heat it to 450°C at a heating rate of 3°C / min for 1 hour to prepare Pd3B (see the picture of the vacuum sealed in the quartz tube mentioned in the above methodfigure 1 ). After the muffle furnace is cooled to room temperatu...

Embodiment 2

[0029]The same as Example 1, except that the sodium tetrachloropalladate and magnesium diboride are simultaneously increased by 2 times the feeding amount, the obtained palladium-boron intermetallic compound is still pure phase. Electrocatalytic performance of the obtained sample: Pd2B: When the overpotential is 18mV, the current density of the material reaches 10mA / cm2; Pd5B2: When the overpotential is 36mV, the current density of the material reaches 10mA / cm2; Pd3B: When the overpotential is 57mV, the current density of the material reaches 10mA / cm2.

Embodiment 3

[0031]Same as Example 1, Pd2The calcination time of B was extended to 4h and 20h respectively, the Pd obtained2The B intermetallic compound is still pure phase. Electrocatalytic performance: Pd obtained by calcination time of 4h2B When the overpotential is 18mV, the current density of the material reaches 10mA / cm2. Pd obtained by calcination time 20h2B When the overpotential is 18mV, the current density of the material reaches 10mA / cm2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com