Continuous extrusion production line for PET foamed sheet

A foamed sheet and production line technology, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of short cooling time, poor cooling effect, and reduced PET sheet molding quality, and improve the quality of delivery. , improve the quality, the effect of stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

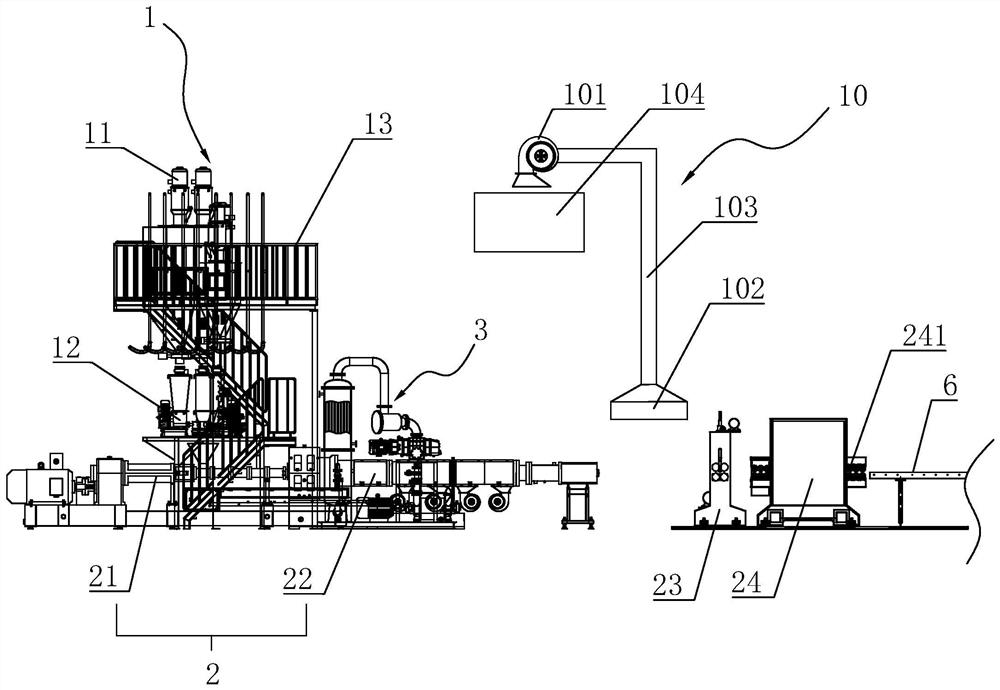

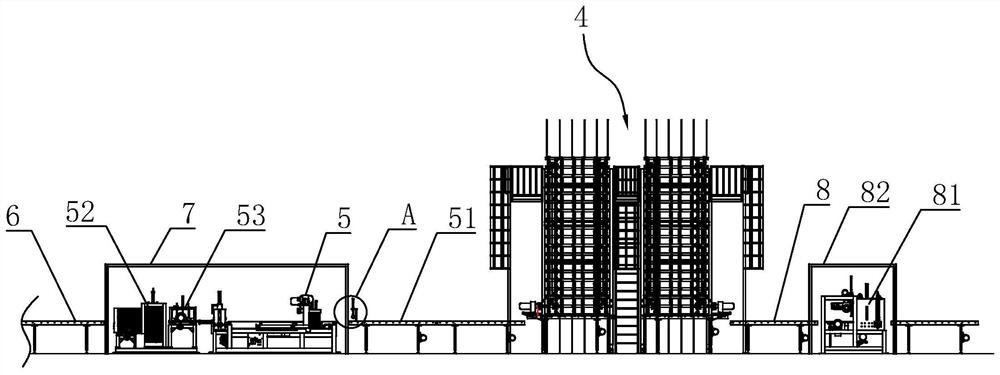

[0039]Example: A continuous extrusion line for PET foamed board, such asfigure 1 withfigure 2 , Including an automatic feeding mechanism 1, an extrusion mechanism 2, a transverse cutting machine 5, a cooling and turning frame 4, and a double-sided planer 81. The material is conveyed to the extrusion mechanism 2 through the automatic feeding mechanism 1 for mixing, heating and extrusion The foamed board is cut into foamed board by the transverse cutting machine 5 and then enters the cooling and turning rack 4 to cool for more than 2 hours. Finally, the foamed board enters the double-sided planer 81 for planing and milling to form the final product and Output.

[0040]Such asfigure 1 , The automatic feeding mechanism 1 includes a vacuum feeding machine 11 and a weightlessness scale 12 located below the vacuum feeding machine 11. The material of the vacuum feeding machine 11 is weighed by a weightlessness scale and then enters the extrusion mechanism 2 for mixing, thereby ensuring The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com