Ion implantation method, preparation method of mercury cadmium telluride chip, and mercury cadmium telluride chip

A technology of ion implantation and mercury cadmium telluride, which is applied in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Effect of surface leakage current and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

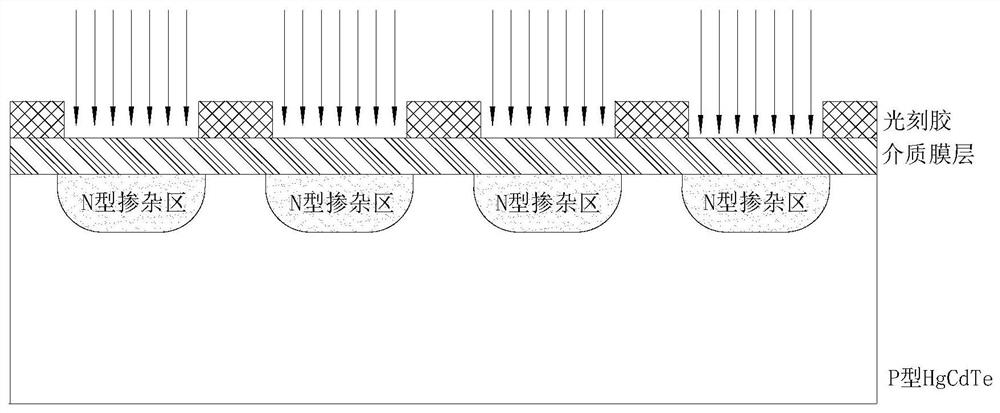

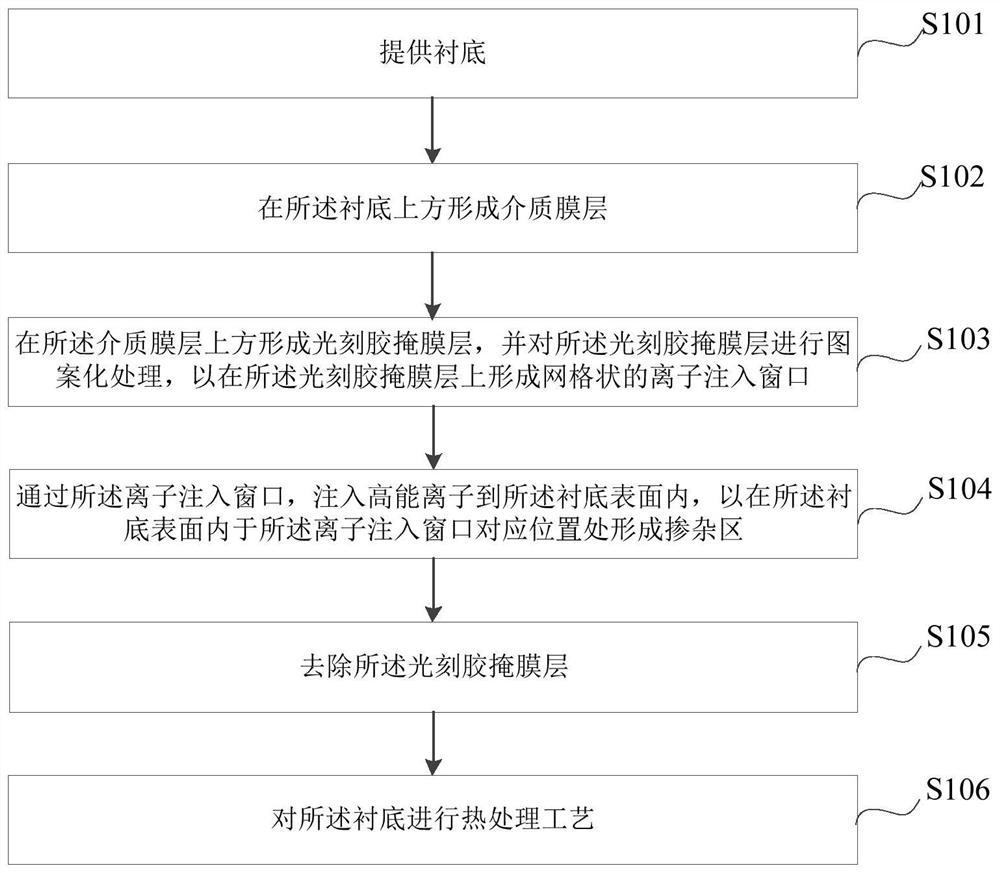

[0044] This embodiment provides an ion implantation method. figure 2 is a schematic flowchart of an ion implantation method shown in an embodiment of the present disclosure. Figure 3-Figure 8 It is a schematic diagram of a cross-sectional structure and a front top view formed by relevant steps of an ion implantation method shown in an embodiment of the present disclosure. Below, refer to figure 2 and Figure 3-Figure 8 The detailed steps of an exemplary method of the ion implantation method proposed by the embodiments of the present disclosure will be described.

[0045] Such as figure 2 As shown, the ion implantation method of this embodiment includes the following steps:

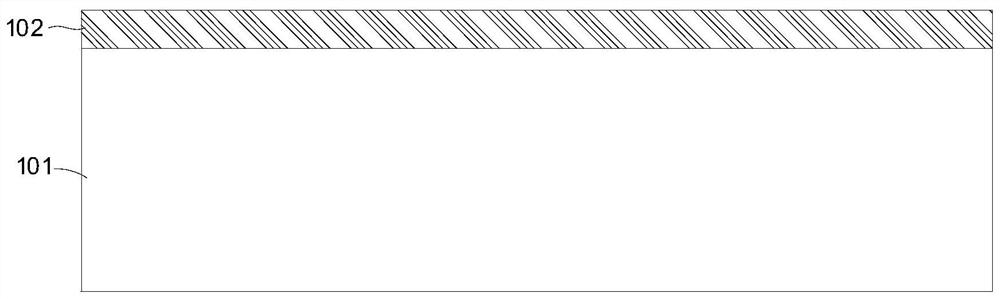

[0046] Step S101: if image 3 As shown, a substrate 101 is provided.

[0047] Step S102 : forming a dielectric film layer 102 on the substrate 101 .

[0048] In this embodiment, the dielectric film layer 102 includes at least one of SiO2, cadmium telluride and zinc sulfide.

[0049] The dielectri...

Embodiment 2

[0066] On the basis of the first embodiment, this embodiment provides a method for manufacturing a mercury cadmium telluride chip. Figure 9 It is a schematic flowchart of a method for preparing a mercury cadmium telluride chip shown in an embodiment of the present disclosure. Figure 10-Figure 16 It is a cross-sectional structure and a front top view schematic diagram formed in the relevant steps of a method for manufacturing a mercury cadmium telluride chip shown in an embodiment of the present disclosure. Below, refer to Figure 9 and Figure 10-Figure 16 The detailed steps of an exemplary method of the method for manufacturing the HgCdTe chip proposed in the embodiments of the present disclosure will be described.

[0067] Such as Figure 9 As shown, the preparation method of the mercury cadmium telluride chip of the present embodiment comprises the following steps:

[0068] Step S201: if Figure 10 As shown, a P-type HgCdTe substrate 201 is provided.

[0069] The P-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com