Gallium nitride enhanced HEMT device and preparation method thereof

An enhancement-mode, gallium nitride technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the inability to guarantee the reliability and stability of enhancement-mode HEMT devices, and reduce the surface state of high-concentration impurities. , reduce defects, improve the effect of on/off current ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

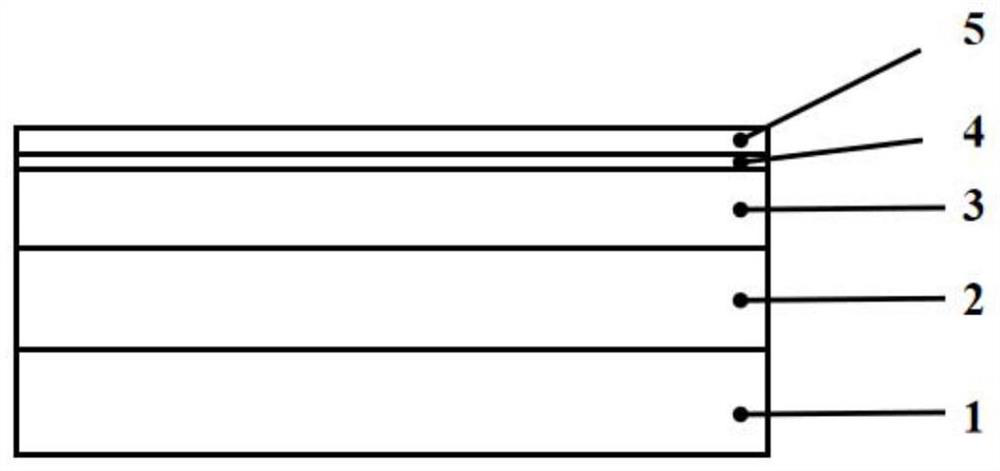

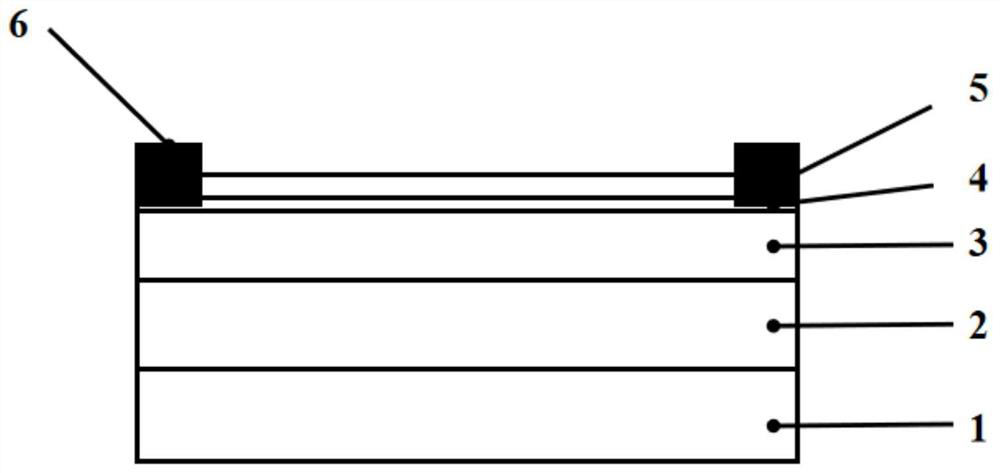

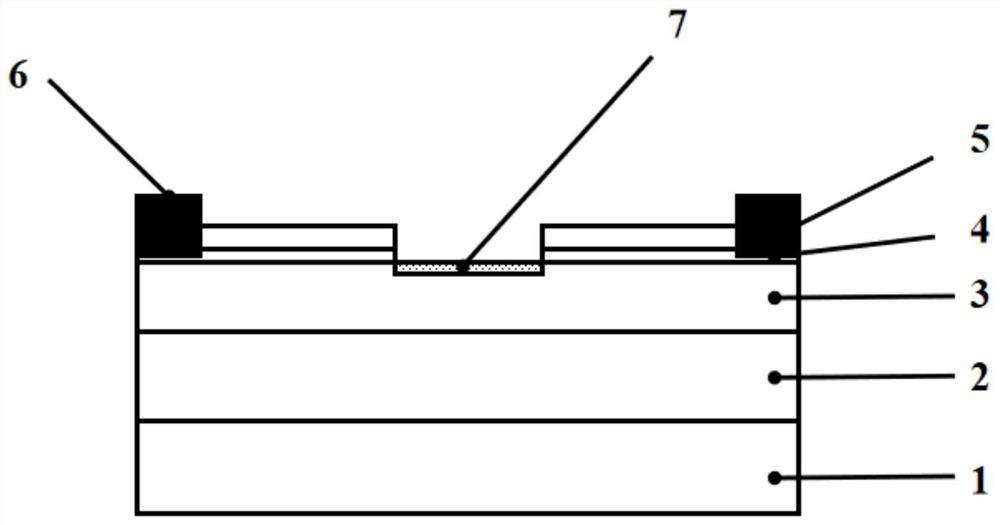

[0058] This embodiment provides a preparation method of a gallium nitride enhanced HEMT device, the structure of the device is as follows Figure 1-4 Shown, its preparation method comprises the following steps:

[0059] (1) Prepare a double-sided polished sapphire substrate.

[0060] (2) Use metal organic chemical vapor deposition (MOCVD) to grow on a sapphire substrate, 10 μm of non-doped GaN as a buffer layer; grow 50 μm of n-type GaN as a GaN layer, and the carrier concentration is about 8x10 16 cm -3 , trimethylhydrogensilane is used as the Si raw material for the n-type dopant (donor).

[0061] (3) On this basis, epitaxially grow AlGaN material as a heterogeneous barrier layer, wherein the Al composition is greater than 0 and less than 0.5, in this embodiment it is 0.2, and the thickness is 50nm; if the Al composition is too high, it is easy to produce Cracks, if the thickness is too low, are not enough to form a two-dimensional electron gas at the GaN material interfa...

Embodiment 2

[0068] This embodiment provides a preparation method of a gallium nitride enhanced HEMT device, the structure of the device is as follows Figure 1-4 Shown, its preparation method comprises the following steps:

[0069] (1) Prepare a double-sided polished GaN substrate.

[0070] (2) Use metal organic chemical vapor deposition (MOCVD) to grow on the GaN substrate, 12 μm of undoped GaN as a buffer layer; grow 60 μm of n-type GaN as the GaN layer, and the carrier concentration is about 8x10 16 cm -3 , trimethylhydrogensilane is used as the Si raw material for the n-type dopant (donor).

[0071] (3) On this basis, epitaxially grow AlGaN material as a heterogeneous barrier layer, wherein the Al composition is greater than 0 and less than 0.5, in this embodiment it is 0.3, and the thickness is 50nm; if the Al composition is too high, it is easy to produce Cracks, if the thickness is too low, are not enough to form a two-dimensional electron gas at the GaN material interface.

[...

Embodiment 3

[0078] This embodiment provides a preparation method of a gallium nitride enhanced HEMT device, the structure of the device is as follows Figure 1-4 Shown, its preparation method comprises the following steps:

[0079] (1) Prepare a double-sided polished GaN substrate.

[0080] (2) Growth on GaN substrate by metal-metal organic chemical vapor deposition (MOCVD), 8 μm of non-doped GaN as a buffer layer; growth of 30 μm n-type GaN as GaN layer, carrier concentration is about 8x10 16 cm -3 , trimethylhydrogensilane is used as the Si raw material for the n-type dopant (donor).

[0081] (3) On this basis, epitaxially grow AlGaN material as a heterogeneous barrier layer, wherein the Al composition is greater than 0 and less than 0.5, in this embodiment it is 0.3, and the thickness is 50nm; if the Al composition is too high, it is easy to produce Cracks, if the thickness is too low, are not enough to form a two-dimensional electron gas at the GaN material interface.

[0082] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com