Impact-resistant splice plate

An impact-resistant, spliced board technology, used in the joining of wooden veneers, floors, wood processing appliances, etc., can solve the problems of weakened mechanical properties, short service life and rapid aging of finger-joint boards, and improve impact resistance. Horizontal and structural stability, reduce external impact damage, strengthen the effect of combining rigidity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

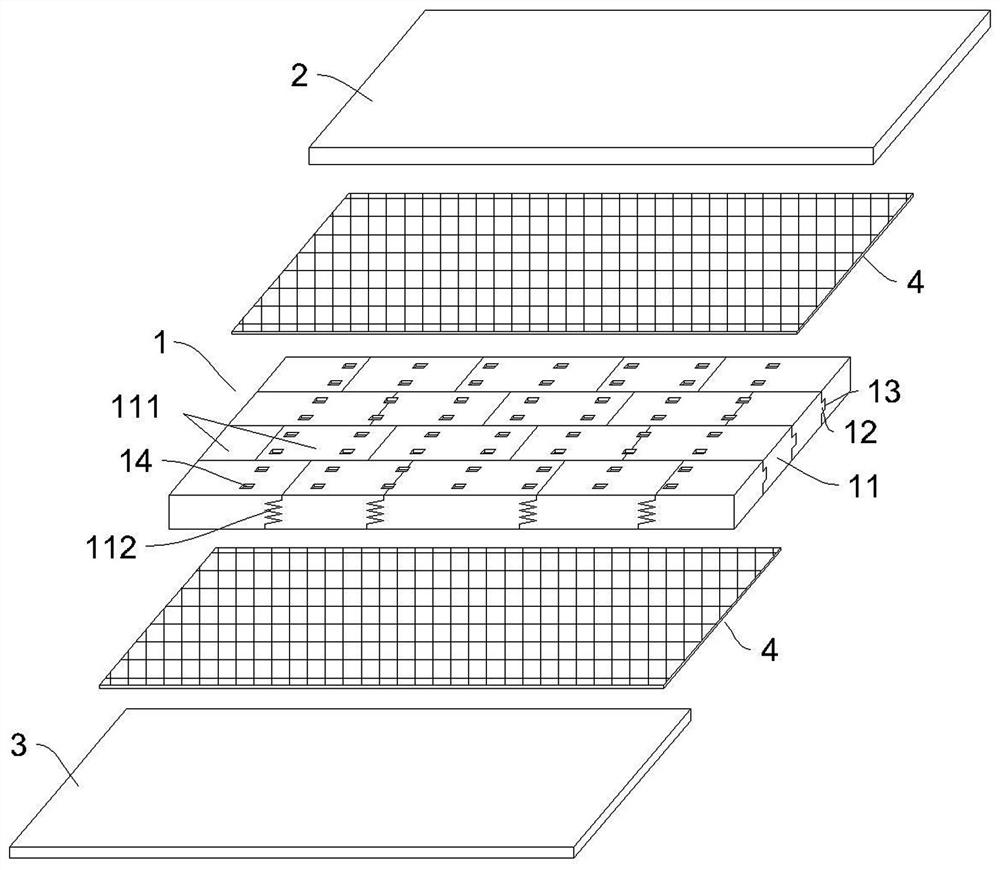

[0037] An impact-resistant splicing board comprises a core layer 1, a surface layer 2 arranged above the core layer 1 and a bottom layer 3 arranged below the core layer 1, wherein the core layer 1, the surface layer 2 and the bottom layer 3 are all wooden boards, the thickness of the core layer 1 is 1.2-1.8 cm, the thickness of the surface layer 2 is 1.2-8 mm, and the thickness of the bottom layer 3 is 0.8-2 mm; Balance layers 4 are respectively arranged between the core layer 1 and the surface layer 2 and between the core layer 1 and the bottom layer 3, and the balance layers 4 are glass fiber mesh or carbon fiber mesh coated with thermoplastic elastomer materials. The core layer 1 is formed by tenoning a plurality of splicing units 11, and the splicing units 11 are formed by continuously fingering a plurality of splicing blocks 111 with the same width and thickness through serrated hidden teeth 112, and the fingering positions of adjacent splicing units 11 are staggered; The ten...

Embodiment 2

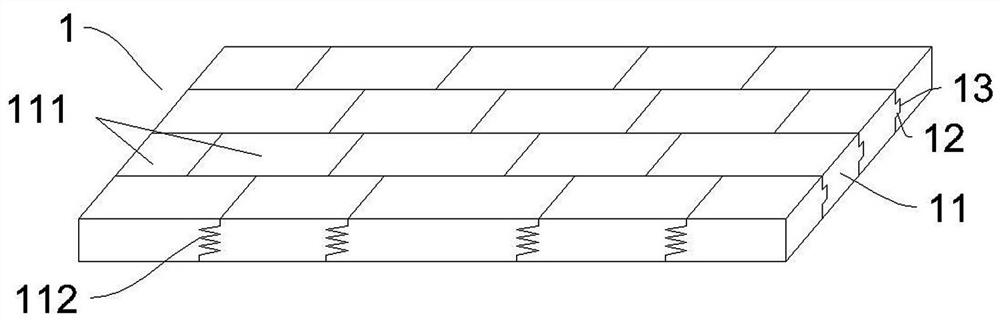

[0040] An impact-resistant splicing board, the basic structure of which is the same as that of Embodiment 1, is only different in that the upper and lower surfaces of the core layer 1 are not provided with penetrating parts 14 (such as Figure 2 Shown).

Embodiment 3

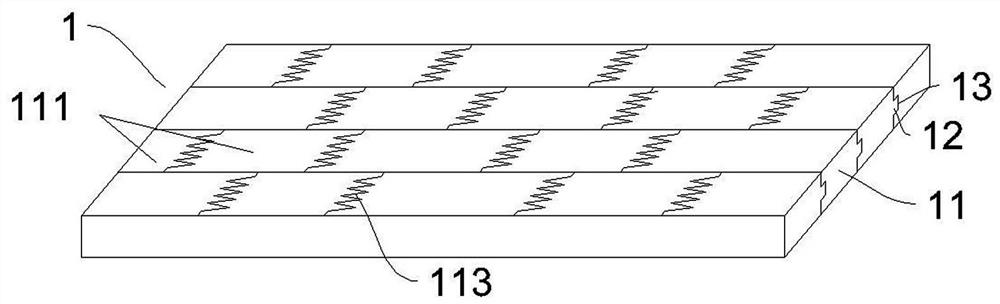

[0042] An impact-resistant splicing board, the basic structure of which is the same as that of Embodiment 2, is only different in that the adjacent splicing blocks 111 on the splicing unit 11 are fingered by the open teeth 113, and the open teeth 113 are also zigzag (for example Figure 3 Shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com