NiTi shape memory alloy with functions of energy absorption and vibration reduction, and preparation method and application thereof

A memory alloy and alloy technology, which is applied in the field of NiTi shape memory alloy and its preparation, can solve the problems of not having high damping characteristics and being unable to effectively suppress high-frequency or low-frequency vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

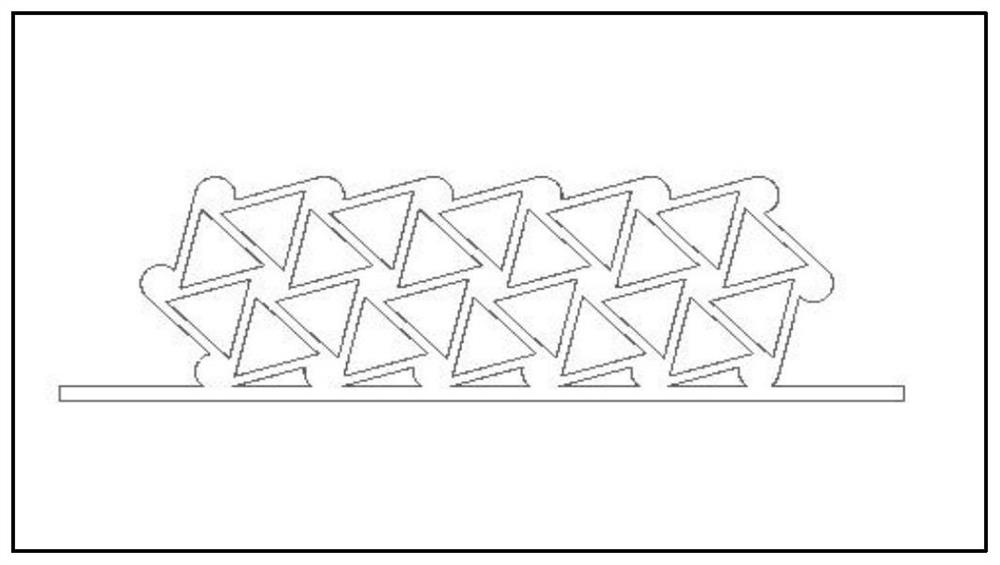

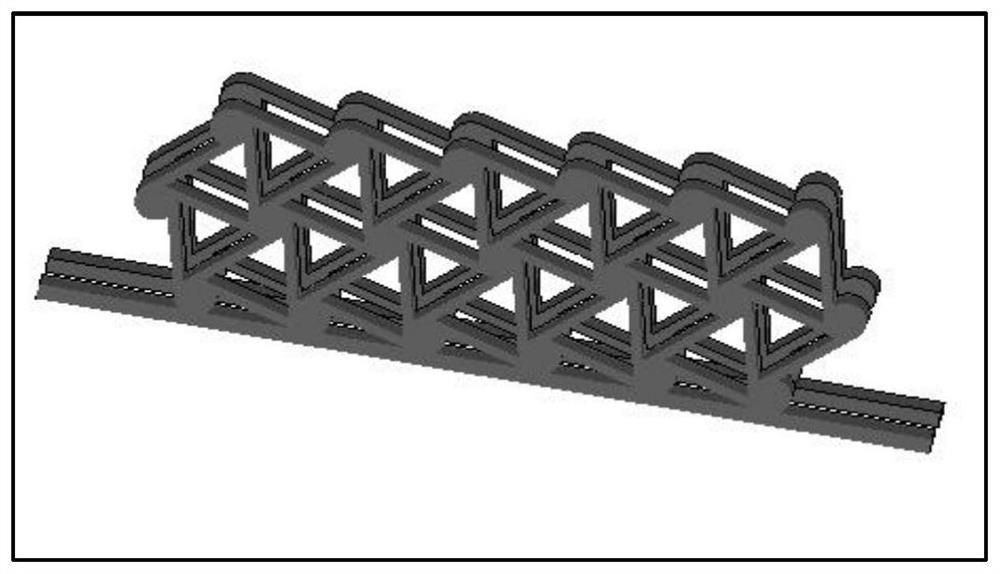

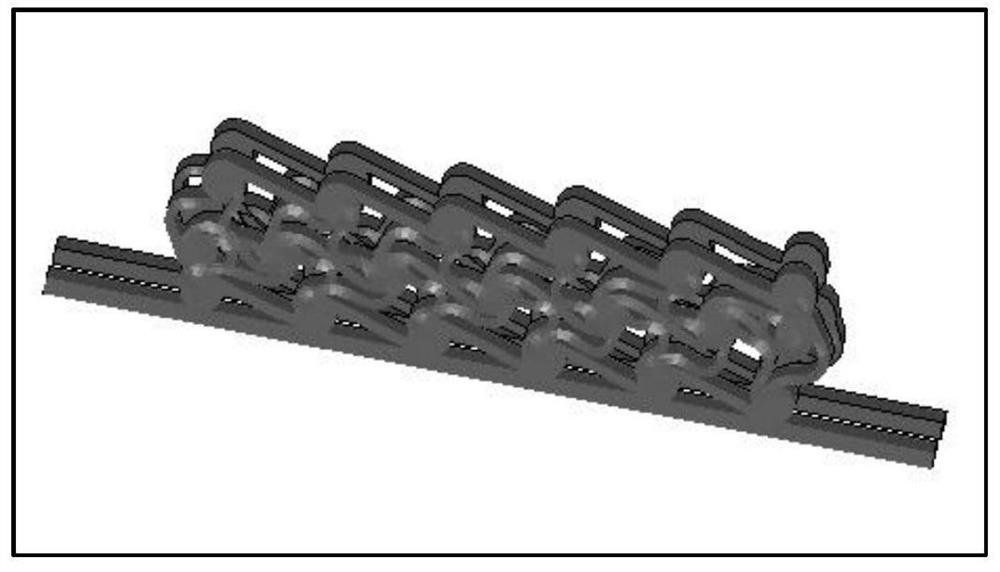

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the alloy, which includes the following steps: (1) annealing the cold deformed nickel-rich NiTi shape memory alloy, the annealing temperature ranges from 100°C to 700°C, and the annealing time ranges from 10 minutes to 200°C Hour;

[0025] (2) Adjust the phase transition temperature of the NiTi alloy by annealing to make the martensitic transformation start temperature (M s ) is lower than the working temperature, while the austenite transformation start temperature (A s ) higher than the operating temperature.

[0026] The cold deformed nickel-rich NiTi shape memory alloy selected in the present invention is preferably plate or wire, and its composition range is preferably 50.1 at.% to 51.5 at.% (atomic fraction) of Ni content, and the total deformation is 10% to 90%. , wherein the last pass cold deformation is 10% to 50%; more preferably Ni content is 50.8at.% to 51.0at.% (atomic fraction), the total deform...

Embodiment 1

[0034] A method for processing a NiTi alloy structure with both energy absorbing and vibration damping functions, comprising the steps of:

[0035] (1) Select a nickel-rich NiTi alloy plate with a total deformation of 70% and a final cold deformation of 25%, with a nickel content of 50.8 at.% (atomic fraction).

[0036] (2) Use the mold to shape the NiTi alloy plate through heat treatment, and control its phase transition temperature and mechanical properties at the same time. The setting temperature is 450°C, and the holding time is 1 hour. The phase transition temperature is as follows: Figure 5 shown. It should be pointed out that two phase transition peaks appear during the cooling process, and the first phase transition peak corresponds to the R-phase phase transition in NiTi alloy. Since the strain corresponding to R-phase transformation is less than 1%, it has little effect on the mechanical properties of NiTi alloy in practical application.

[0037] (3) After the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com