Ceramic powder and application thereof

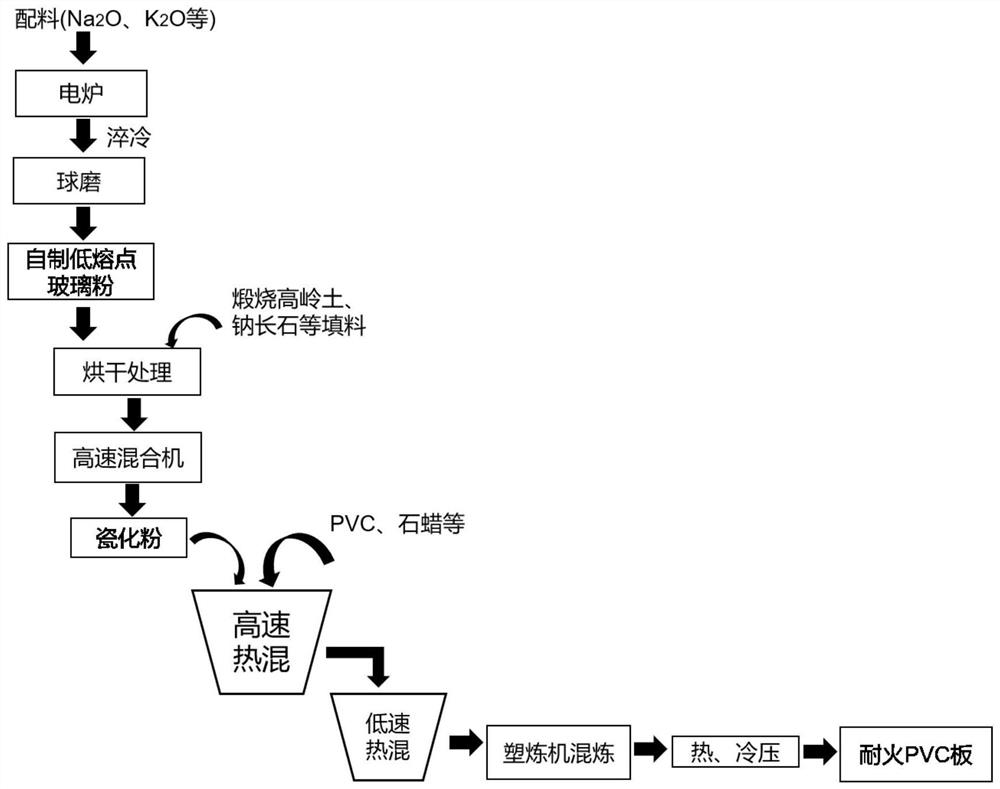

A technology for ceramic powder and glass powder is applied in the processing and application field of inorganic composite powder, which can solve the problems of low flame resistance and low temperature resistance, and achieve the effect of improving the performance of porcelain, denser structure and less cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

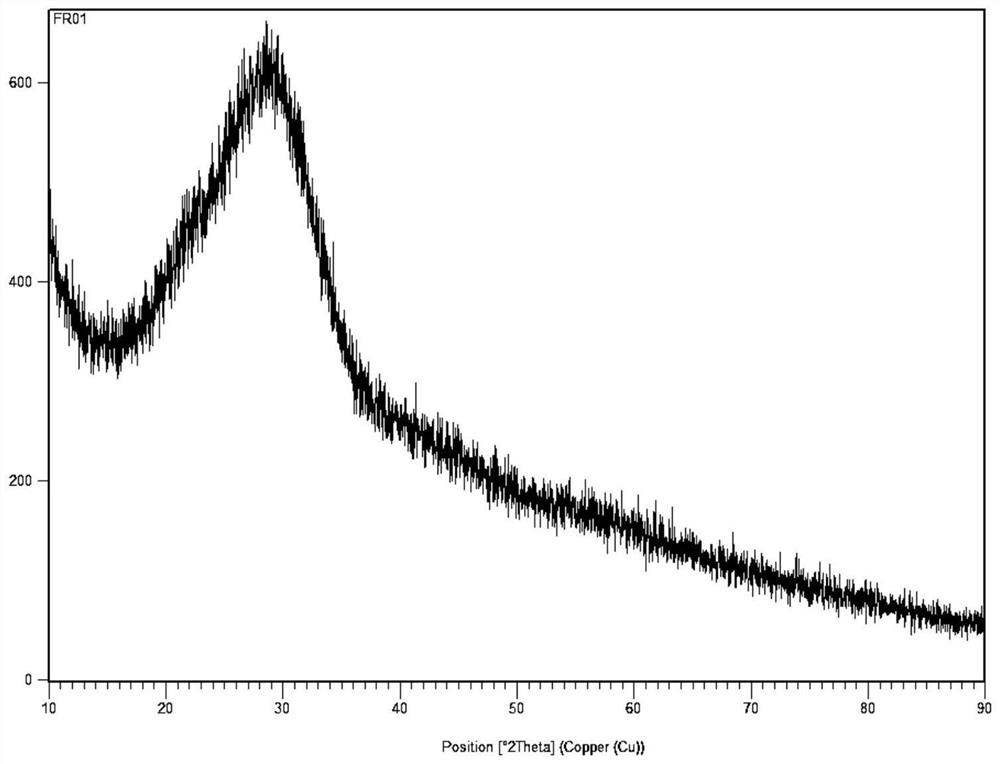

[0028] Weigh 8g Na by mass percentage 2 O, 22gK 2 O, 24gAl 2 o 3 , 42gP 2 o 5 , 2gCaO, 2gSiO 2 . Fully mix the weighed raw materials, then put the mixture into a crucible, put it into an electric furnace with a furnace temperature of 300 °C, keep it warm for 1 hour, and perform preheating treatment, then raise the temperature to 1200 °C, and keep it warm for 2 hours, and the melted The molten glass was poured into cold water and quenched to obtain granular glass, which was milled in a ball mill (the time was 12 hours, and the rotating speed was 400r / min), and passed through a 800-mesh sieve to obtain 98g of homemade low-melting glass powder.

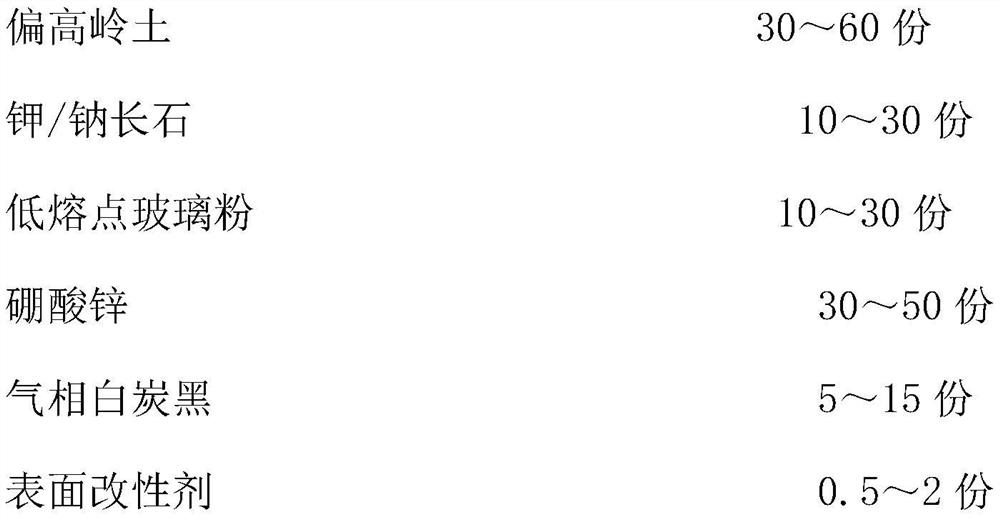

[0029] Weigh 120g metakaolin (Shanghai Yantai Industrial Co., Ltd., model TX801), 40g albite (Lingshou Chuanshi Mineral Products Processing Plant, model N-800), 30g self-made low melting point glass powder (800 mesh), 80g boric acid Zinc (Jinan Sennuo New Material Technology Co., Ltd., model SN-303), fumed silica 20g (Changzhou Le...

Embodiment 2

[0032] Weigh 14gNa by mass percentage 2 O, 18gK 2 O, 23gAl 2 o 3 , 39gP 2 o 5 , 3gCaO, 3gSiO 2 . Fully mix the weighed raw materials, then put the mixture into a crucible, put it into an electric furnace with a furnace temperature of 300 °C, keep it warm for 1 hour, and perform preheating treatment, then raise the temperature to 1200 °C, and keep it warm for 2 hours, and the melted The molten glass is poured into cold water and quenched to obtain flaky and granular glass, which is ball milled in a ball mill (the time is 12 hours and the rotating speed is 400r / min), and passed through a 800 mesh sieve to obtain 97g of self-made low melting point glass powder .

[0033]Weigh 120g of metakaolin, 40g of albite, 60g of self-made low-melting glass powder (800 mesh), 80g of zinc borate, and 20g of fumed silica, and put them into a blast drying oven for drying treatment at a temperature of 110°C. for 2 hours, then put the dried powder into a high-speed mixer for pre-mixing (te...

Embodiment 3

[0036] Weigh 11gNa by mass percentage 2 O, 20gK 2 O, 28gAl 2 o 3 , 35gP 2 o 5 , 3gCaO, 3gSiO 2 . Fully mix the weighed raw materials, then put the mixture into a crucible, put it into an electric furnace with a furnace temperature of 300 °C, keep it warm for 1 hour, and perform preheating treatment, then raise the temperature to 1200 °C, and keep it warm for 2 hours, and the melted The molten glass is poured into cold water and quenched to obtain flake and granular glass, which is ball milled in a ball mill (the time is 12 hours and the speed is 400r / min), and passed through a 800-mesh sieve to obtain 98g of self-made low-melting glass powder .

[0037] Weigh 60g of metakaolin, 60g of albite, 60g of self-made low-melting glass powder (800 mesh), 100g of zinc borate, and 20g of fumed silica, and put them into a blast drying oven for drying treatment at a temperature of 110°C. for 2 hours, then put the dried powder into a high-speed mixer for pre-mixing (temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com