Regeneration and reactivation method of heavy distillate oil hydrotreatment catalyst

A heavy distillate and hydrotreating technology, which is applied in the direction of catalyst regeneration/reactivation, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve environmental pollution and other problems, reduce production costs, increase effective surface area, The effect of increasing the degree of sulfidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

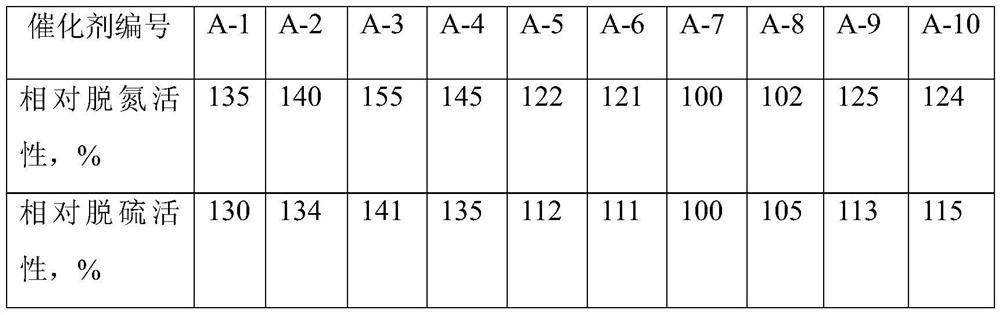

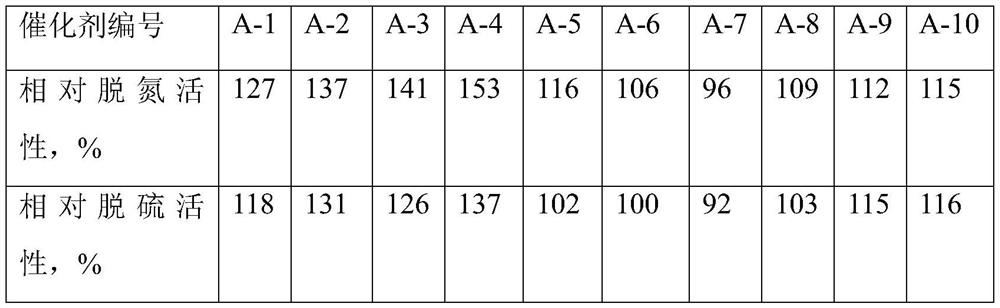

Embodiment 1

[0037] A certain amount of charcoal-fired catalyst A1 was weighed, and impregnated with an aqueous solution containing phosphoric acid, tartaric acid and glycerol by ultrasonic impregnation. The molar ratio of phosphorus, tartaric acid and glycerol in the impregnation solution to the total metal atoms on the regeneration agent is 0.02:0.08:0.06:1, the power of the ultrasonic wave is 1:0W / ml, the frequency is 45kHZ, the temperature is 45°C, and the time is After impregnation, the sample was dried at room temperature for 25 minutes. The first drying temperature was 100°C and the drying time was 8 hours. The second drying temperature was 180°C and the drying time was 30 minutes to obtain catalyst A-1.

Embodiment 2

[0039] A certain amount of charcoal-fired catalyst A2 was weighed and impregnated with an aqueous solution containing phosphoric acid, malic acid and glycerol by ultrasonic impregnation. The molar ratio of phosphorus, malic acid and glycerol in the solution to the total metal atoms on the regeneration agent is 0.03:0.1:0.02:1, the ultrasonic power is 15W / ml, the frequency is 60kHZ, the temperature is 35°C, and the time is 30min After impregnation, the sample was dried at room temperature. The first drying temperature was 130°C, and the drying time was 6 hours. The second drying temperature was 160°C, and the drying time was 75 minutes to obtain catalyst A-2.

Embodiment 3

[0041]A certain amount of charcoal-fired catalyst A3 was weighed and impregnated with an aqueous solution containing phosphoric acid, citric acid and butanediol by ultrasonic impregnation. The molar ratio of phosphorus, citric acid, butanediol to the total metal atoms on the regenerant in the solution is 0.02:0.3:0.08:1, the power of the ultrasonic wave is 15W / ml, the frequency is 50kHZ, the temperature is 30°C, and the time is 30min , after impregnation, the sample was dried at room temperature, the first drying temperature was 100°C, and the drying time was 10 hours, and the second drying temperature was 170°C, and the drying time was 100 minutes to obtain catalyst A-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com