Denitrfying agent and method for desulfurizing and denitrating refractory bricks by using denitrfying agent

A technology for desulfurization, denitrification and denitrification agent, which is applied in the field of denitrification agent and refractory brick desulfurization and denitrification. It can solve the problems of leaching toxicity, difficult and efficient use of waste, and large consumption. It achieves uniform distribution of porosity and density, and realizes pollution-free recycling. , the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

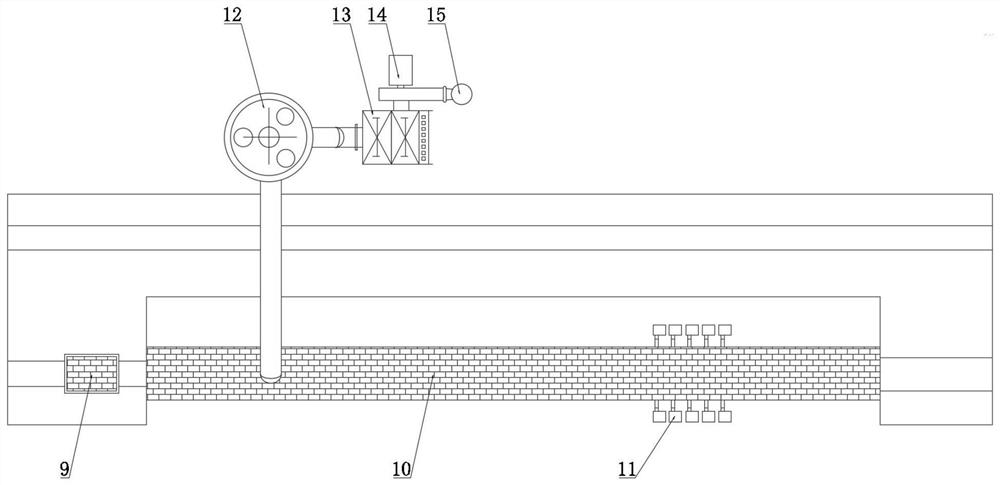

[0047] see figure 1 , the invention discloses a denitrification agent, which comprises the following components by mass percentage: 95% aluminum ash powder, 5% binder; in this embodiment, the binder is water or glass glue thinner;

[0048] The denitrification agent is prepared through the following steps:

[0049] S1: The primary aluminum ash is sent from the primary aluminum ash storage bin 1 to the ball mill 3 for grinding through the conveyor 2, and the ground aluminum ash is screened on the screening machine 4 to obtain the secondary aluminum ash powder raw material; The primary aluminum ash powder comprises 16-22% aluminum nitride by weight, 18-25% aluminum oxide, and 12-17% aluminum, and the remaining ingredients include sodium, potassium, calcium salts, etc.; the ball mill 3 ball mills The time is 60 minutes, and the primary aluminum ash powder is ground until 80% of the particle size passes through a sieve with a pore size of 125 μm, and the sieving machine 4 at leas...

Embodiment 2

[0054] see figure 1 , the invention discloses a denitrification agent, the denitrification agent comprises the following components by mass percentage: 97% aluminum ash powder, 3% binder; in this embodiment, the binder is water or glass glue thinner;

[0055] The denitrification agent is prepared through the following steps:

[0056] S1: The primary aluminum ash is sent from the primary aluminum ash storage bin 1 to the ball mill 3 for grinding through the conveyor 2, and the ground aluminum ash is screened on the screening machine 4 to obtain the secondary aluminum ash powder raw material; The primary aluminum ash powder comprises 16-22% aluminum nitride by weight, 18-25% aluminum oxide, and 12-17% aluminum, and the remaining ingredients include sodium, potassium, calcium salts, etc.; the ball mill 3 ball mills The time is 90 minutes, and the primary aluminum ash powder is ground until 80% of the particle size passes through a sieve with a pore size of 125 μm, and the sievi...

Embodiment 3

[0061] see figure 1 , the invention discloses a denitrification agent, the denitrification agent comprises the following components by mass percentage: 99% aluminum ash powder, 1% binder; in this embodiment, the binder is water or glass glue thinner;

[0062] The denitrification agent is prepared through the following steps:

[0063] S1: The primary aluminum ash is sent from the primary aluminum ash storage bin 1 to the ball mill 3 for grinding through the conveyor 2, and the ground aluminum ash is screened on the screening machine 4 to obtain the secondary aluminum ash powder raw material; The primary aluminum ash powder comprises 16-22% of aluminum nitride, 18-25% of aluminum oxide, 12-17% of aluminum, and the remaining components include sodium. Potassium, calcium salt, etc.; the milling time of the ball mill 3 is 120min, and the primary aluminum ash is ground until 80% of the particle size passes through a screen with an aperture of 125 μm, and the screen 4 at least incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com