Method for preparing Ti2AlNb-based composite material of imitated shell laminated structure by combining powder metallurgy and forging

A composite material and powder metallurgy technology, applied in the field of preparing Ti2AlNb-based composite materials, can solve the problems of weak bonding strength of the interface between the reinforcement and the matrix, high content of impurity elements, poor organization uniformity, etc., so as to reduce the content of impurities and increase the specific surface area. , the effect of reducing the ball milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

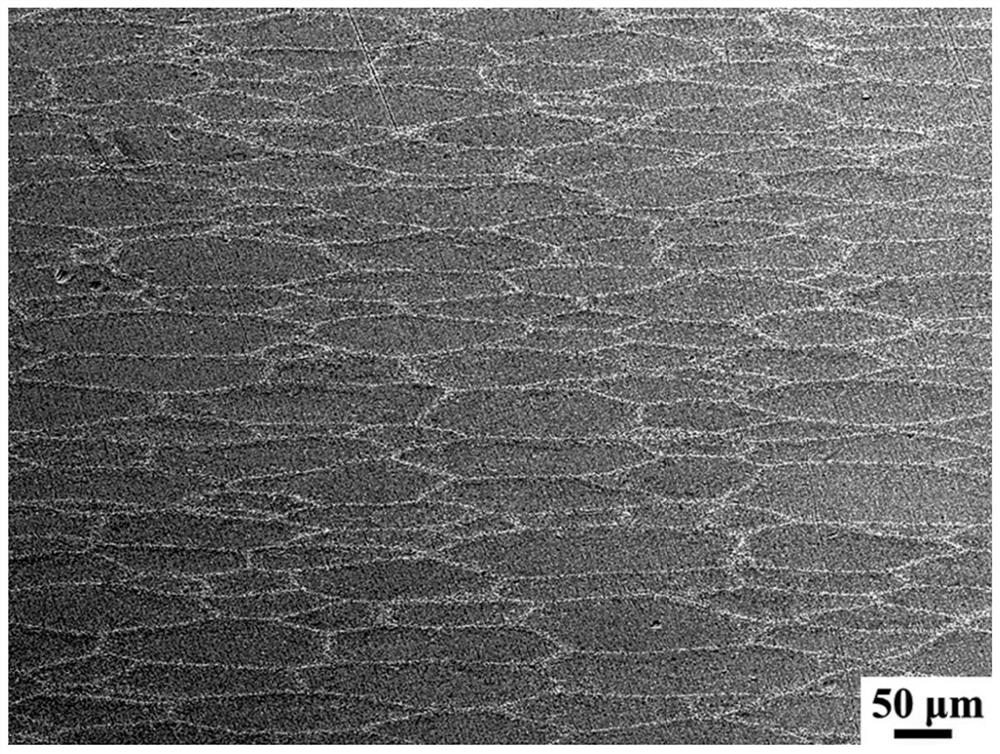

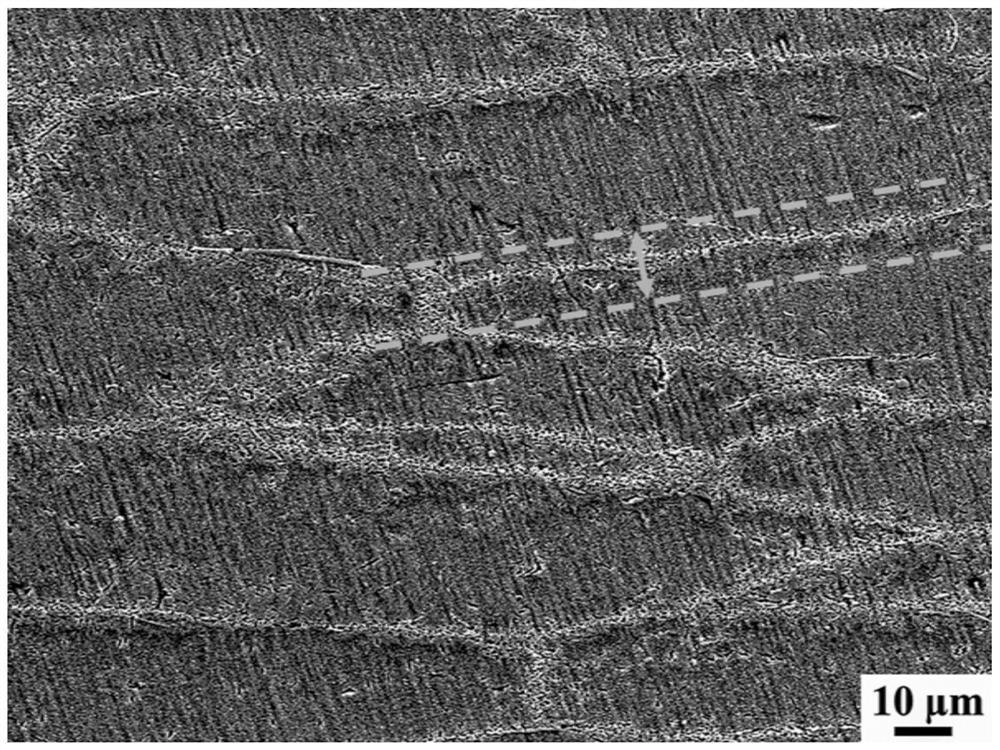

[0024] Specific Embodiment 1: In this embodiment, the method of combining powder metallurgy and forging to prepare a shell-like structure Ti2AlNb-based composite material is carried out according to the following steps:

[0025] 1. Weighing of raw materials

[0026] Weigh 0.4%~10% LaB by mass fraction 6 Powder, 0.2%~20% TiB 2 The spherical Ti2AlNb alloy powder of powder and surplus is as raw material;

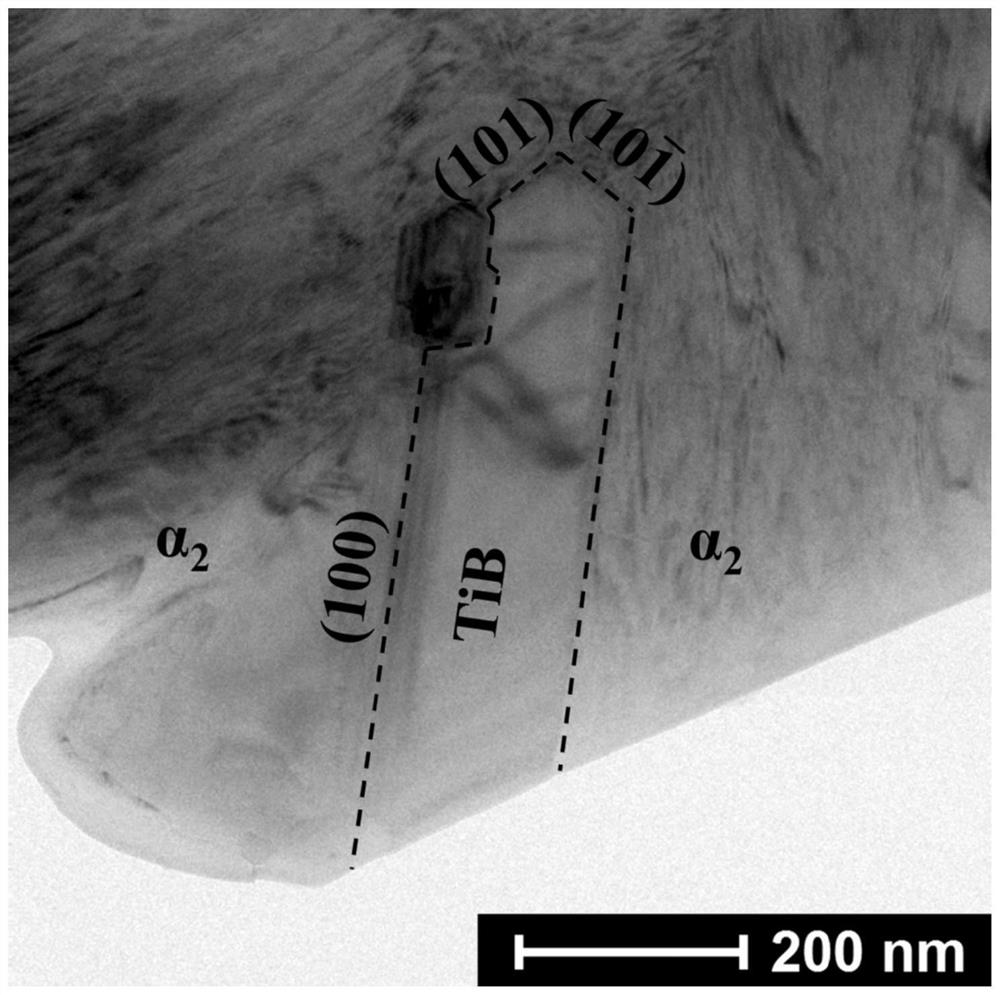

[0027] 2. Preparation of boride-coated Ti2AlNb alloy powder

[0028] Mixing the raw materials weighed in step 1 and performing ball milling to obtain Ti2AlNb alloy powder coated with boride;

[0029] 3. Sintering of composite materials

[0030] Sintering the Ti2AlNb alloy powder coated and inlaid with boride in step 2 to obtain a sintered composite material;

[0031] 4. One-way upsetting of the sintered composite material, and then remove the sheath, that is to say, it is completed.

[0032] This embodiment has the following beneficial effects:

[0033] 1. This embodimen...

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the atomic percentage of Al in the spherical Ti2AlNb alloy powder described in step one is 15% to 27%, the atomic fraction of Nb is 10% to 30%, Mo, The sum of the atomic percentages of Ta, Si, W and Fe is 0% to 5%, and Ti is the balance.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the particle size distribution range of the spherical Ti2AlNb alloy powder in step 1 is 0.5D to 2D, and D is the average particle size of the spherical Ti2AlNb alloy powder, and D =5~200μm; the LaB 6 The average particle size of 0.1 ~ 10μm; the TiB 2 The average particle size is 0.1-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com