Method for realizing diffusion bonding of aluminum oxide ceramic based on aluminum oxide-titanium-nickel

A technology of alumina ceramic and diffusion connection, applied in the field of welding, can solve the problems of difficult connection and poor weldability, and achieve the effect of expanding the effective contact area, preventing oxidation and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Place Ni and Ti sheets with thicknesses of 0.05mm and 0.05mm respectively on two pieces of Al with thicknesses of 1mm 2 o 3 Al 2 o 3 -Ti-Ni-Ti-Al 2 o 3 Then, place it in a graphite mold, tighten it with a constant torque wrench, apply a pressure of 5kPa, and anneal it in a vacuum carbon tube furnace with argon gas. The reaction temperature is 1350°C, and the holding time is 6h.

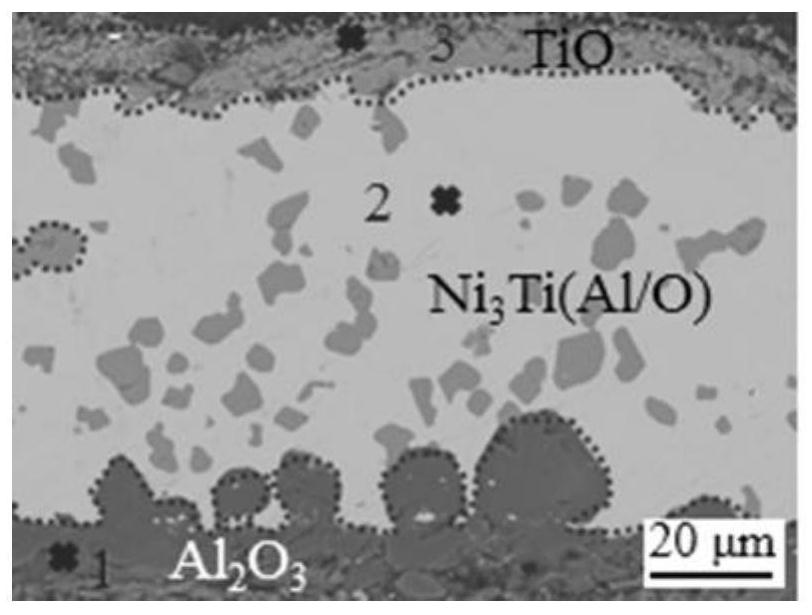

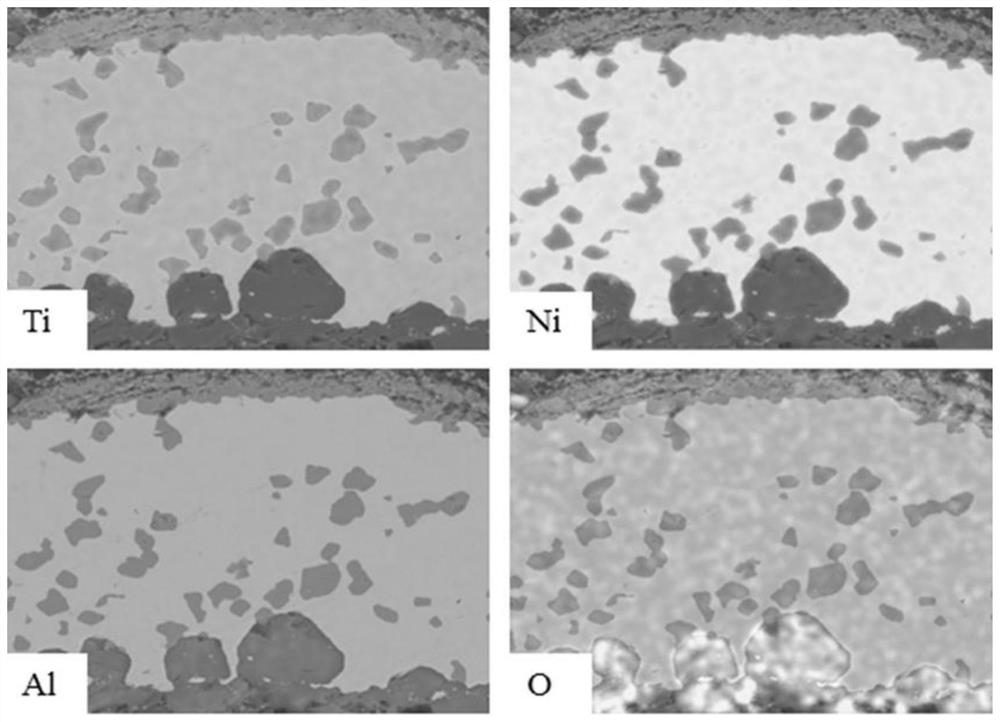

[0030] see figure 1 and figure 2 , the diffusion is very uniform, Al 2 o 3 Diffusion occurs in Al, Ni and Ti at the same time, the sample is cut along the direction perpendicular to the interface, and the interface is tested by SEM and EDS. The results show that nickel, titanium and alumina react chemically to form Ni 3 Ti(Al / O) solid solution and TiO.

Embodiment 2

[0032] Place Ni and Ti sheets with thicknesses of 0.06mm and 0.06mm respectively on two pieces of Al with thicknesses of 2mm 2 o 3 Al 2 o 3 -Ti-Ni-Ti-Al 2 o 3 Then, place it in a graphite mold, tighten it with a constant torque wrench, apply a pressure of 4kPa, and anneal it in a vacuum carbon tube furnace with argon gas. The reaction temperature is 1400°C, and the holding time is 10h.

[0033] The samples were cut along the direction perpendicular to the interface, and the interface was tested by SEM and EDS. The results show that nickel, titanium and alumina react chemically to form Ni 3 Ti(Al / O) solid solution and TiO.

Embodiment 3

[0035] Place Ni and Ti sheets with thicknesses of 0.08mm and 0.08mm respectively on two pieces of Al with thicknesses of 3mm 2 o 3 Al 2 o 3 -Ti-Ni-Ti-Al 2 o 3 Then, place it in a graphite mold, tighten it with a constant torque wrench, apply a pressure of 3kPa, and anneal it in a vacuum carbon tube furnace with argon gas at a reaction temperature of 1450°C and a holding time of 4h.

[0036] The samples were cut along the direction perpendicular to the interface, and the interface was tested by SEM and EDS. The results show that nickel, titanium and alumina react chemically to form Ni 3 Ti(Al / O) solid solution and TiO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com