Laser welding process of casing and bearing sleeve of mobile phone motor stator assembly

A motor stator, laser welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult to spread glue evenly, product failure rate increased, connection reliability impact, etc., to achieve consistent appearance and size Good performance, fast laser welding speed, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

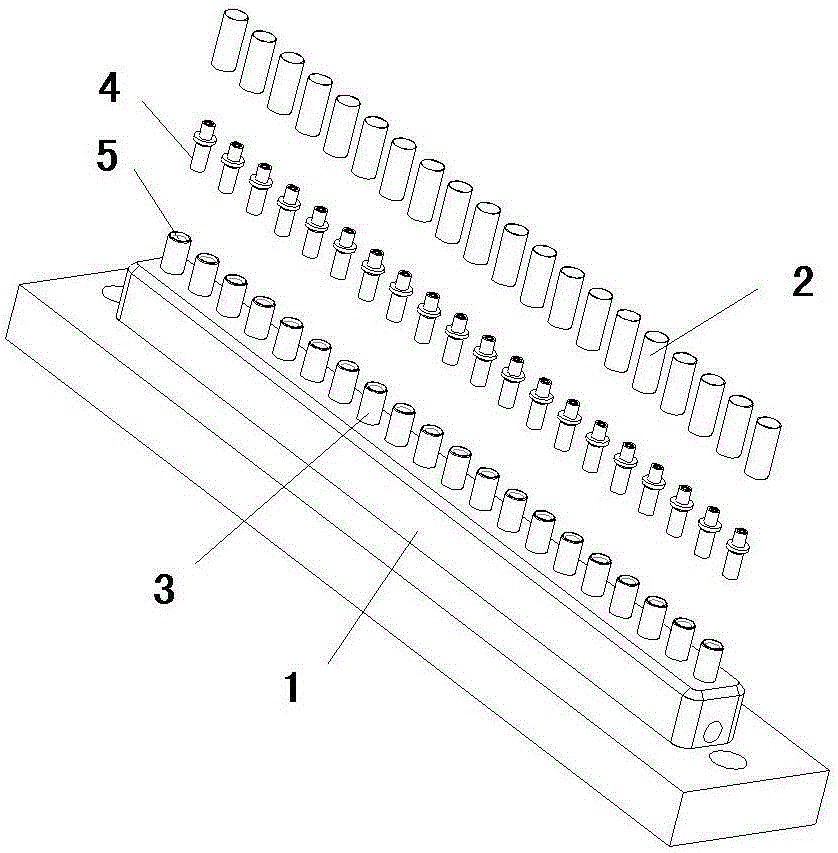

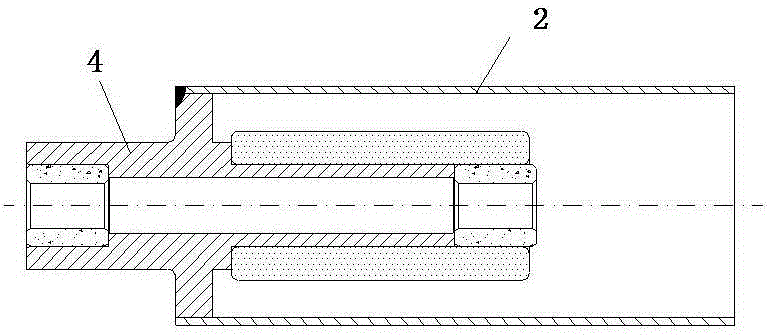

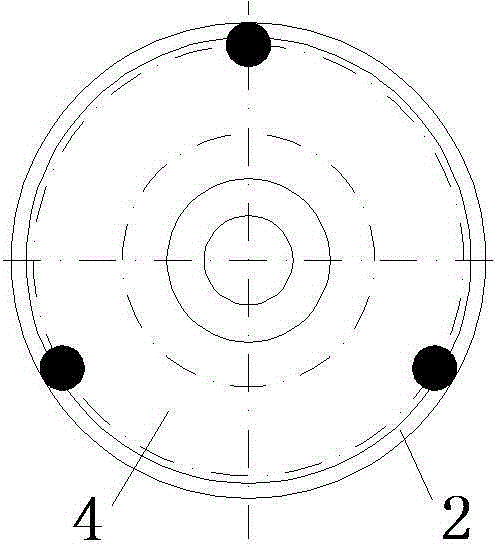

[0046] In the laser welding process of the mobile phone motor stator assembly casing and the bearing sleeve in this embodiment, after the mobile phone motor stator assembly is assembled on the turnover mold bar, the parameters of the laser welding used are: the output frequency of the laser welding machine is 50 Hz, and the welding current The welding pulse width is 70mA, the laser spot diameter is 0.1mm, that is, the welding duration of each welding point is 4ms, and the welding speed is 13mm / s. There are three annular uniformly distributed laser beams between the casing 2 and the bearing sleeve. solder joints, such as figure 2 and image 3 shown.

no. 2 example

[0048] In the laser welding process of the mobile phone motor stator assembly casing and the bearing sleeve in this embodiment, after the mobile phone motor stator assembly is assembled on the turnover mold bar, the parameters of the laser welding used are: the output frequency of the laser welding machine is 1 Hz, and the welding current 80mA, the laser spot diameter is 0.1mm, the welding pulse width—that is, the welding duration of each welding point is 3.5ms, and the welding speed is 10mm / s. Laser welding points, such as Figure 4 and Figure 5 shown.

no. 3 example

[0050] In the laser welding process of the mobile phone motor stator assembly casing and the bearing sleeve in this embodiment, after the mobile phone motor stator assembly is assembled on the turnover mold bar, the parameters of the laser welding used are: the output frequency of the laser welding machine is 100Hz, and the welding current The welding pulse width is 75mA, the laser spot diameter is 0.1mm, the welding pulse width—that is, the welding duration of each welding point is 4.5ms, and the welding speed is 11.5mm / s. Fabric laser welding points, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com