Insulated metal valve

A technology of insulating metal and valves, applied in the field of valve processing, can solve the problems of failure to realize the insulation and anticorrosion of special-shaped supporting equipment, anode current loss, electrochemical corrosion, etc., and achieve the effects of novel structure, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The insulated metal valve of the present invention not only has its usual functions, but also has excellent insulation and anti-corrosion properties. In the application, it can insulate and isolate the sections of the gas transmission and distribution pipeline, the gas pressure regulating station and the gas transmission and distribution pipeline, so that The anode current will not be lost to the soil through the metal valve, protecting it from electrochemical corrosion.

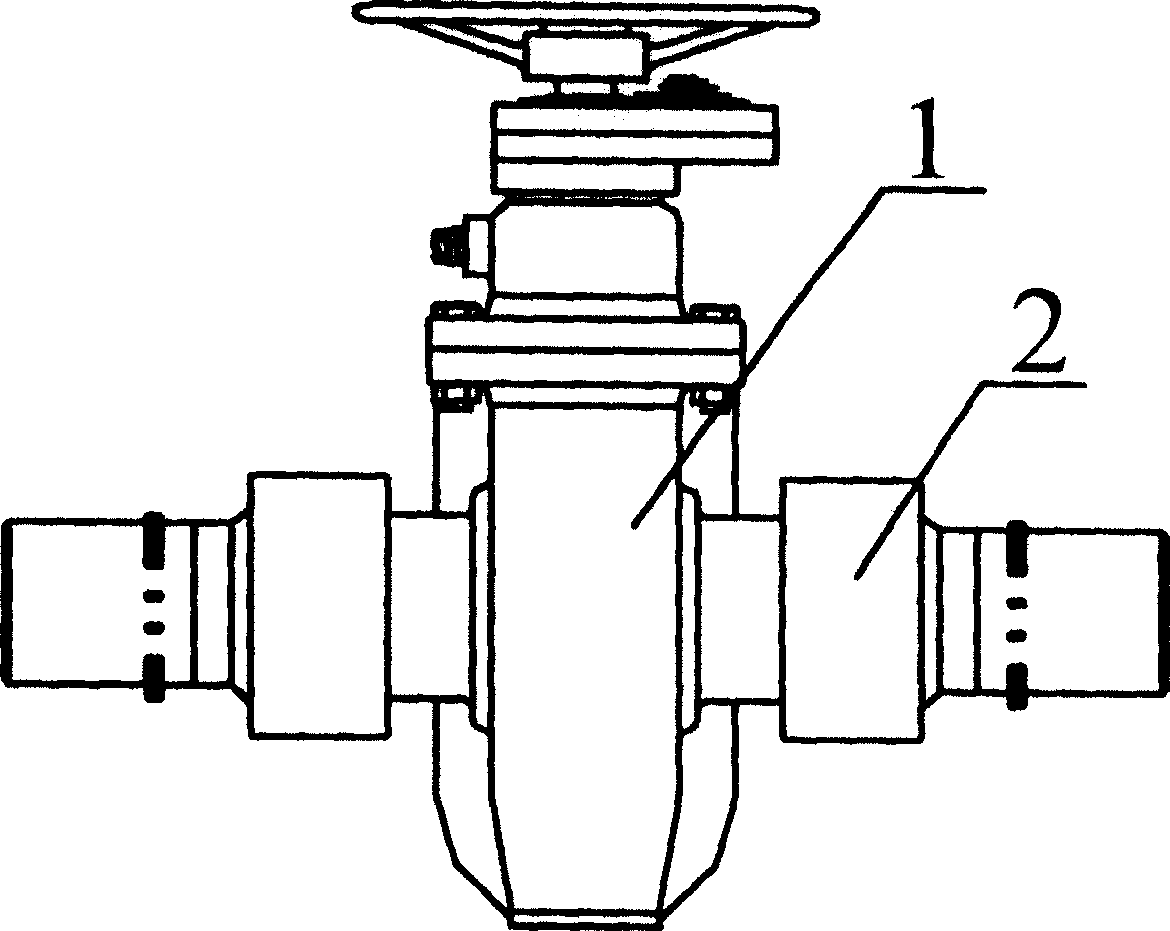

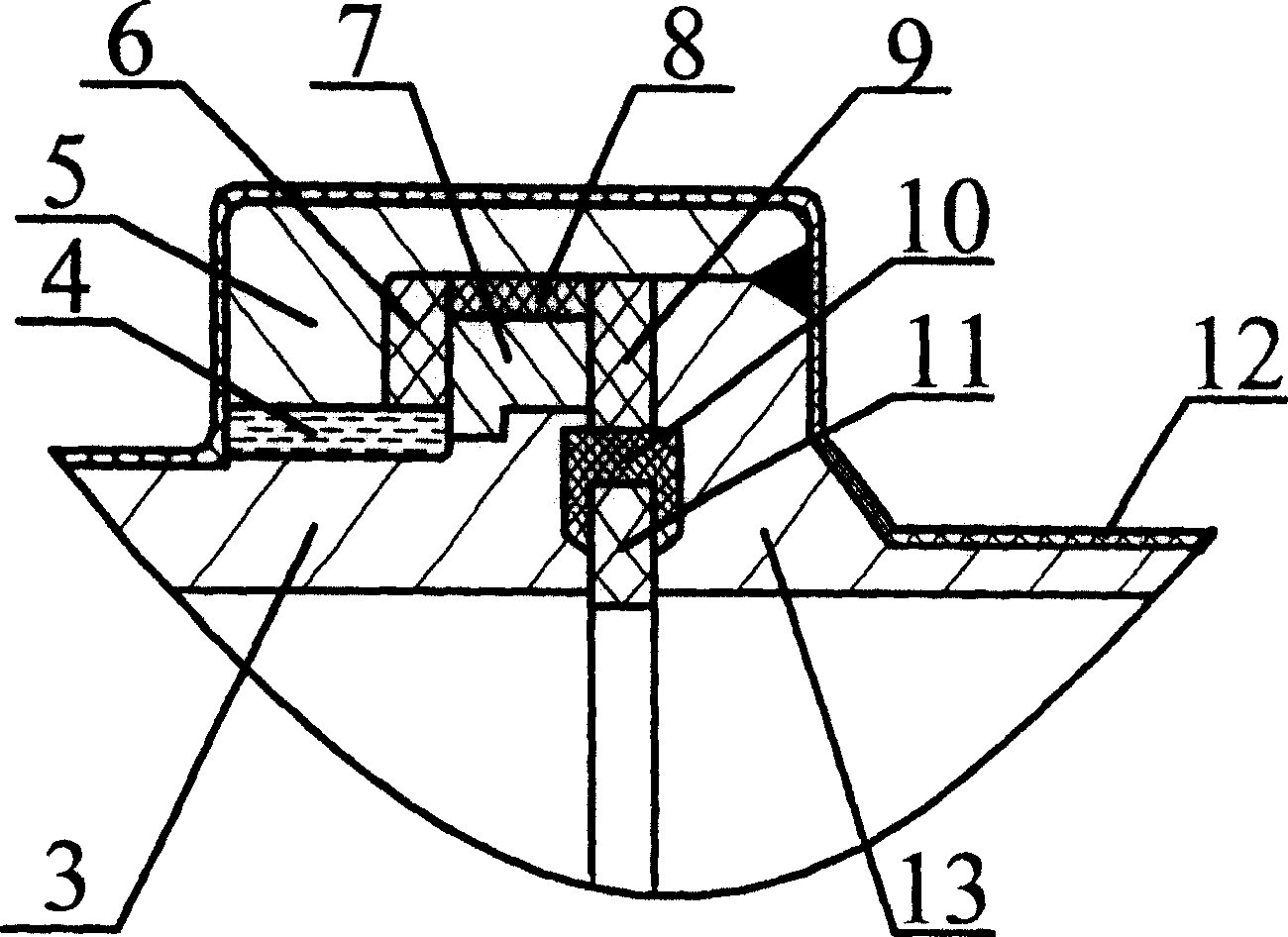

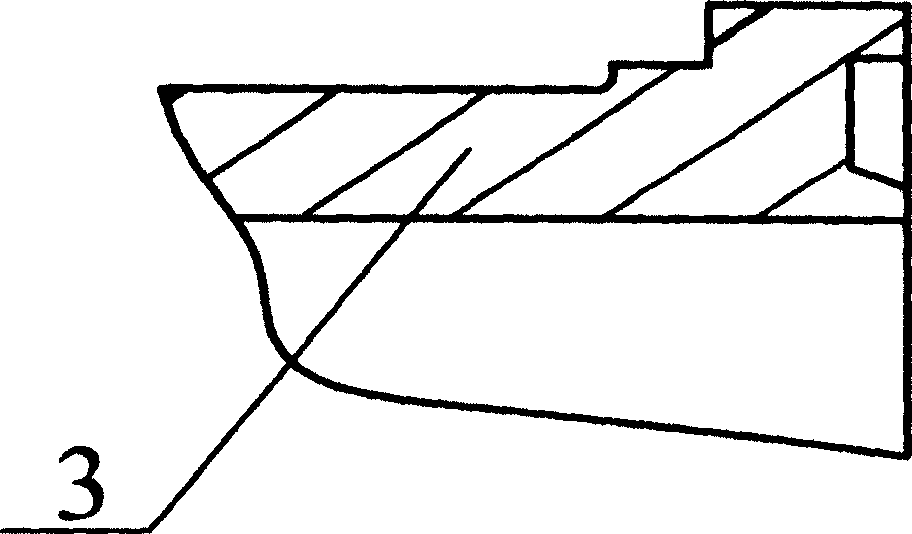

[0021] like figure 1 ,like figure 2 Shown: an insulating metal valve, including the valve body 1, the inlet of the valve and the outlet of the valve, the two interfaces of the valve shell are provided with an insulating structure 2, and the insulating structure 2 includes: a hook sleeve 5, a half ring 7, a poly Tetrafluoroethylene fixed ring 8, insulating ring A6, insulating ring B9, insulating ring C11, insulating sealing ring 10, conduit 13 and epoxy resin 4, the hook sleeve 5 is set on the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com