Efficient polyurethane asphalt anticorrosive coating

An anti-corrosion coating and polyurethane technology, applied in the coating field, can solve the problems of low temperature curing, water immersion resistance, brittle coating film, etc., and achieve the effect of good salt water resistance, good construction performance and excellent performance.

Inactive Publication Date: 2013-12-11

TIANCHANG JULONG TRAVEL PAINT

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, antistatic coatings are mainly anti-corrosion coatings composed of epoxy resin, conductive pigments, fillers, conductive additives, solvents, etc., but the coating film is brittle and has the defect that it cannot be cured at low temperature, and it will rust soon after construction. Resistance to water immersion, etc., these problems will cause serious consequences

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

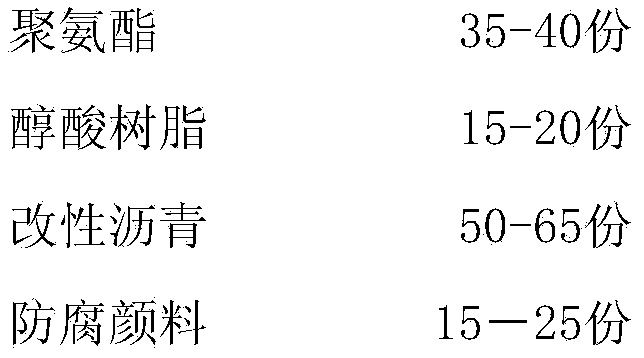

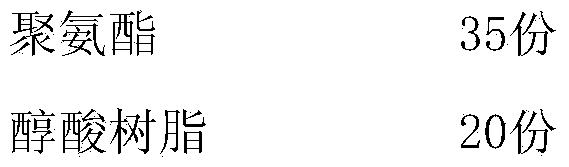

Embodiment 1

[0020]

[0021]

Embodiment 2

[0023]

Embodiment 3

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an efficient polyurethane asphalt anticorrosive coating which is prepared from polyurethane, alkyd resin, modified asphalt, anticorrosive pigment and gallotannic acid in parts by weight. According to the invention, the idea of adding polyolefins modified asphalt into a polyurethane coating system to improve the surface elasticity of a coating film of the coating, high-and-low-temperature resistant transforming ability and the like is innovatively proposed, the preservation time of a product is as long as to be up to or even more than 5 years, meanwhile, composited zinc sulfate with a good anticorrosive property is taken as the anticorrosive pigment, the composited zinc sulfate takes part in transforming the slight corrosion, so that the tolerance of the coating on a base material and the adhesion force of the paint film are increased, furthermore, the gallotannic acid capable of reacting with a base material steel is added, so that the labor intensity is reduced, the rust adhered to the surface is removed, and the adhesion force of the paint film is increased.

Description

technical field [0001] The invention relates to the technical field of coatings, in particular to a high-efficiency polyurethane asphalt anticorrosion coating. Background technique [0002] With the rapid development of the petroleum and chemical industries, the protection of the inner and outer surfaces of petroleum storage tanks has attracted more and more attention. Because crude oil contains sulfide and water, and minerals will corrode the inner wall of the oil tank, and the static electricity generated by the friction of the inner wall of the oil tank will cause the combustion and explosion of the oil. Therefore, the inner and outer walls of oil storage tanks, oil pipelines, oil tankers, tankers and other oil storage and oil transportation equipment in petroleum, chemical, railway, transportation and other industries need to be coated with a layer of anti-corrosion and anti-static protection coating layer. [0003] The national standard GB50393-2008 "Technical Specific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D195/00C09D175/04C09D167/08C09D5/08

Inventor 汪鹏程祝盆鑫孙巨福戴宇钧

Owner TIANCHANG JULONG TRAVEL PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com