A welding process for aluminum alloy new energy vehicle power bearing device

A new energy vehicle and bearing device technology, which is applied in the field of aluminum alloy welding, can solve the problems of unfavorable energy saving and emission reduction of automobiles, and its own weight is large, and achieve the effects of improving battery life, reducing weld defects, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below.

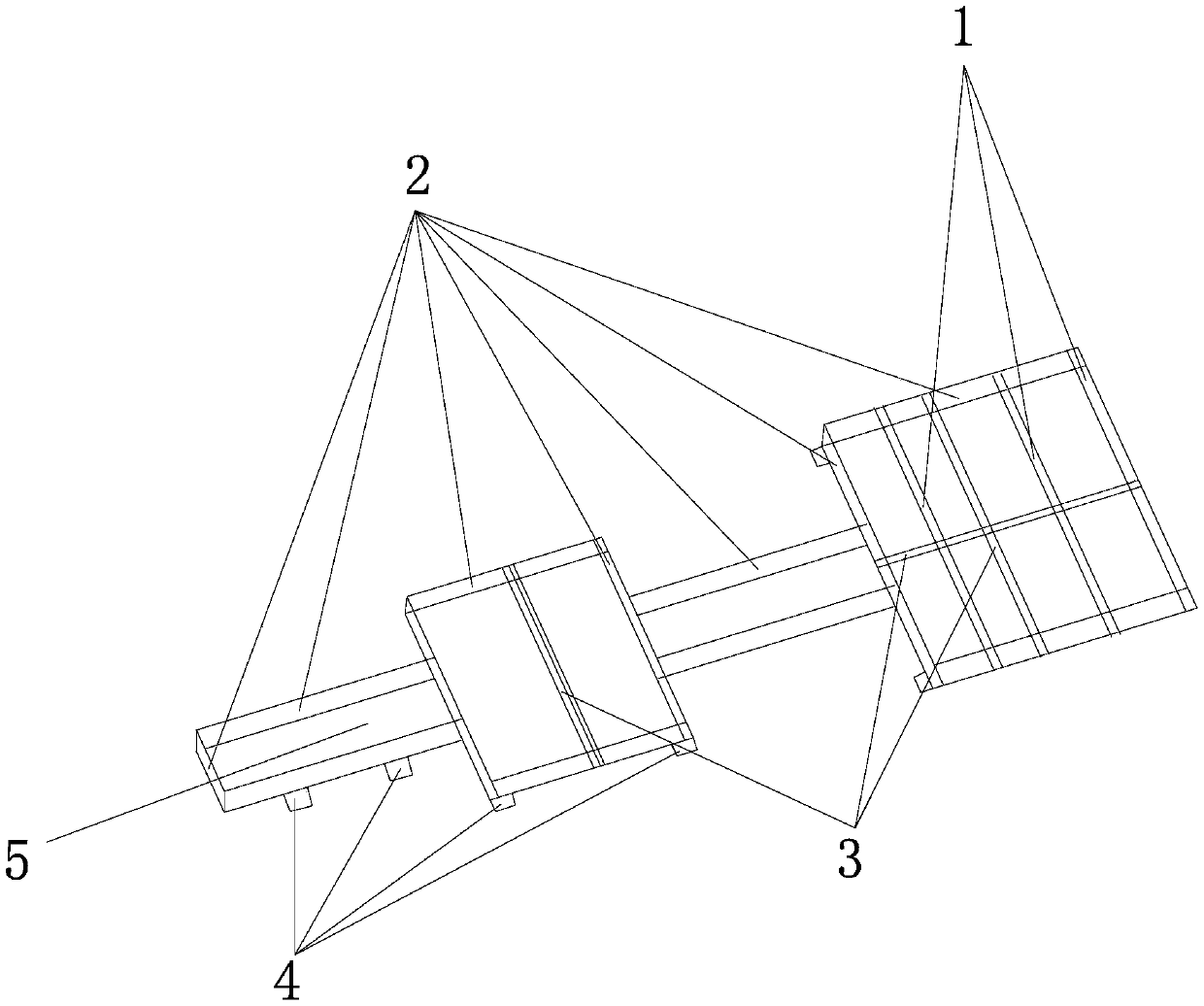

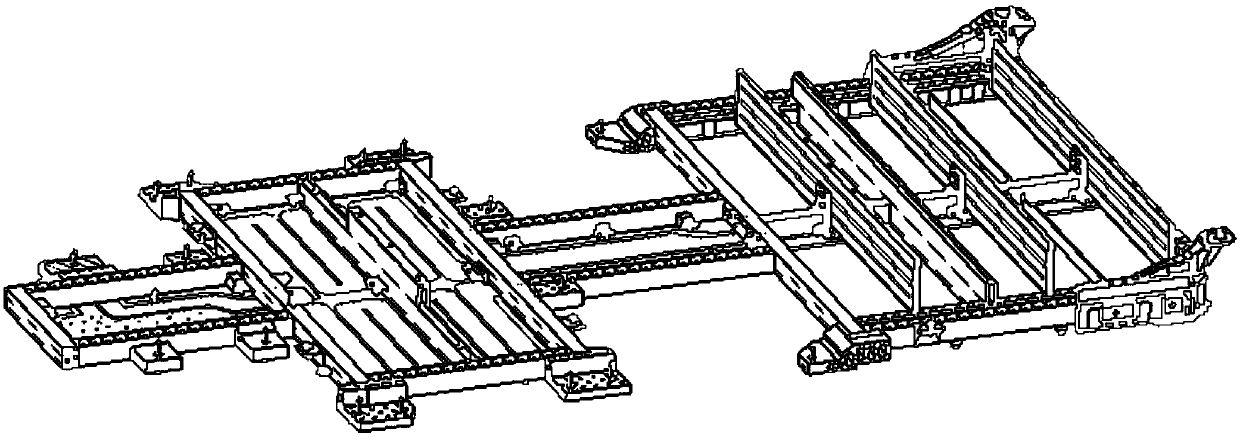

[0028] The reference signs in the accompanying drawings of the specification include:

[0029] Upper water cooling plate 1, frame 2, support beam 3, mounting support 4, bottom plate 5.

[0030] Such as Figure 1~2 The automotive power bearing device made of all aluminum alloy is shown, the material of the automotive power bearing device is 6061-T6 aluminum plate, and the thickness of the aluminum plate is one of 2mm, 3mm and 4mm. The welding equipment is Rpanasonic YC-300BP Panasonic electric welding machine, the shielding gas is Ar gas, the welding material used is aluminum welding wire ER5356, and the diameter of the aluminum welding wire is 2.4mm. The vehicle power bearing device is welded by 13 outermost frames 2, 3 parallel upper water cooling plates 1 and lower water cooling plates, 3 support beams, 1 bottom plate 5 and 14 mounting supports 4 at the bottom of the power bearing de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com