Manufacturing process of high alumina-silica glass square flash point effect

A manufacturing process, high-alumina-silicon technology, applied in glass production, chemical instruments and methods, surface etching compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

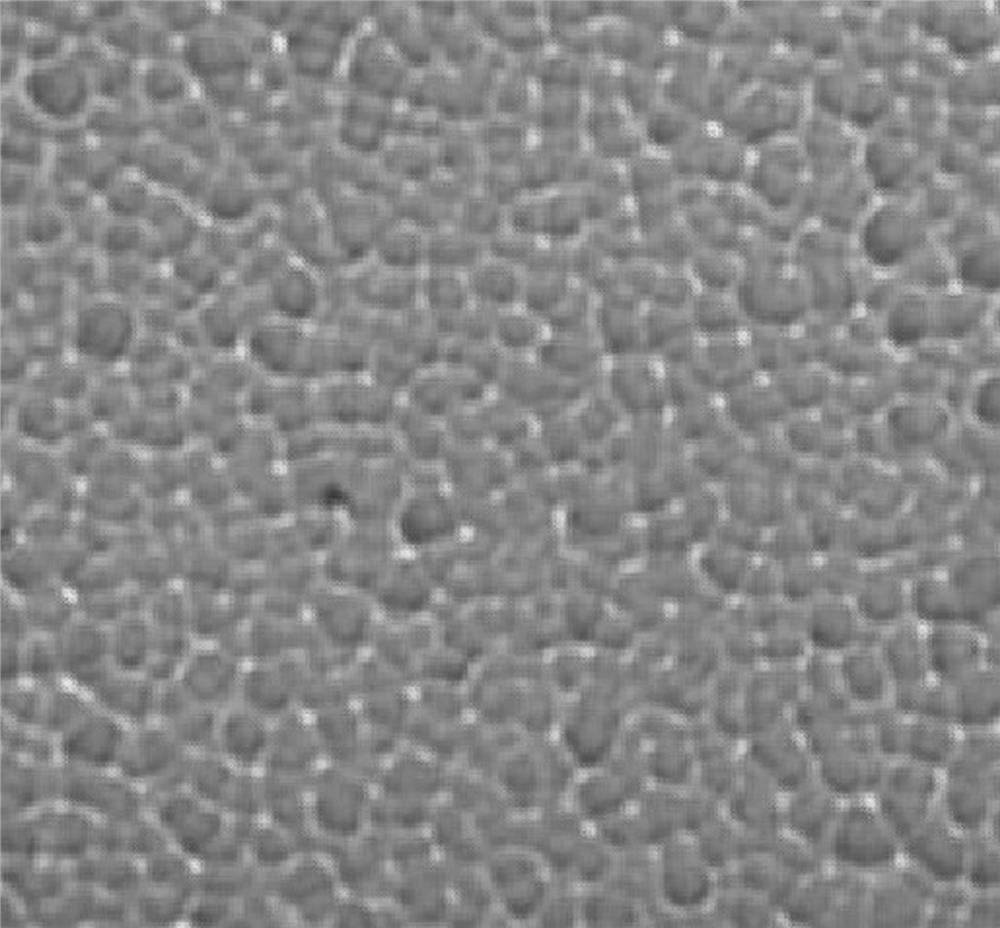

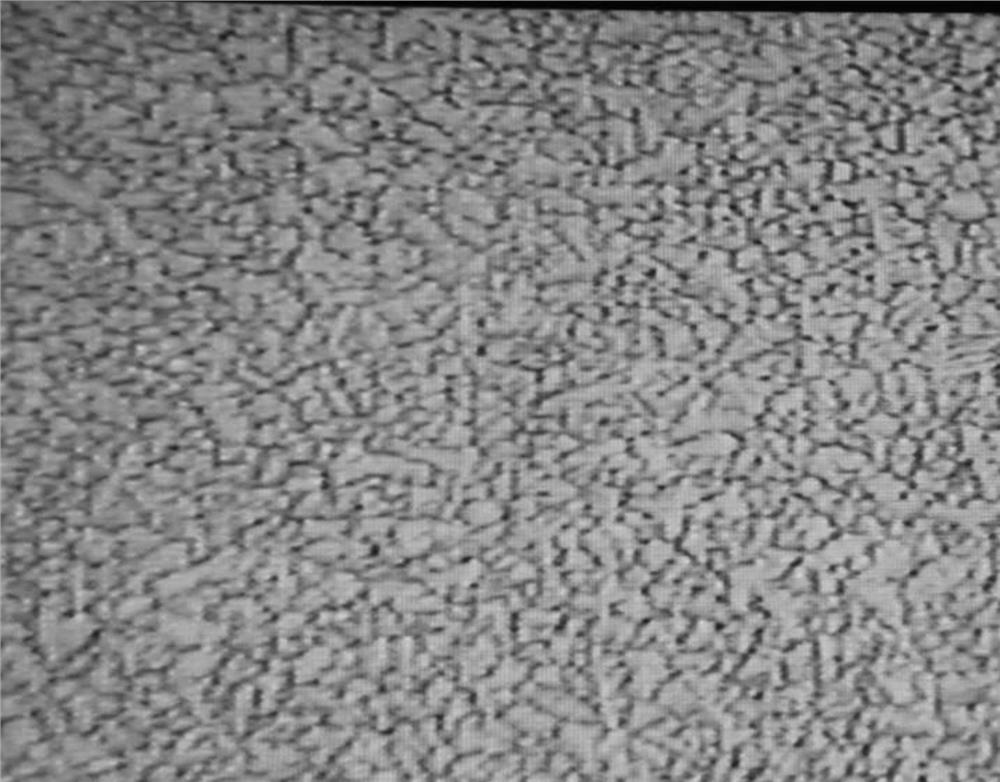

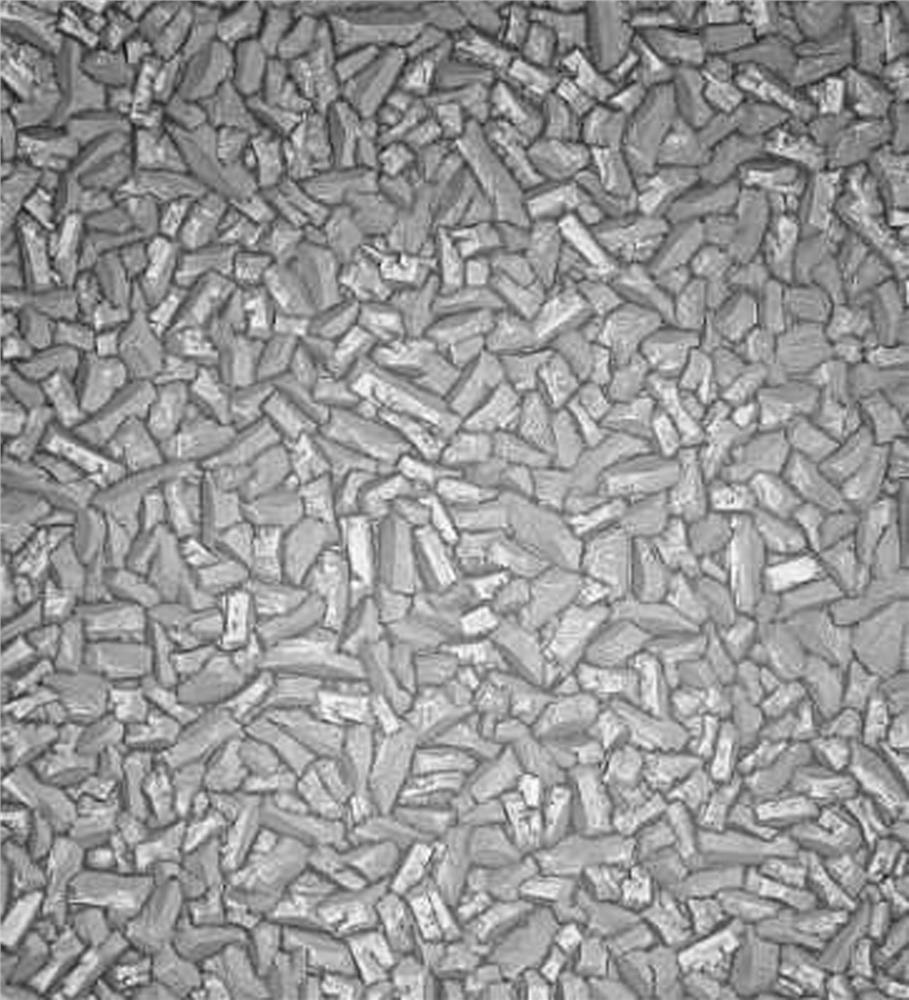

Image

Examples

Embodiment 1

[0019] A manufacturing process of square flash point effect of high alumina silicate glass, comprising the following steps:

[0020] (1) Configure high-alumina-silicate glass square flash point effect etching solution, stir evenly until the etching solution is in a uniform supersaturated solution state, and place the etching solution in the etching sand shower device;

[0021] The high-alumina silica glass square flash point effect etching solution is composed of the following raw materials in mass fraction: 18% NH 4 HF 2 , 3% KHF 2 , 5% NH 4 F. 15% HNO 3 , 8% H 2 SO 4 , 3% HCl, 5% MgSiF 6 , 6% BaSO 4 , 2% NaNO 3 , 0.5% K 2 SO 4 , 0.8% CuCl 2 , 1.2% CaCl 2 , 3% starch, 1% maltose, 15% H 2 O.

[0022] (2) Cover and protect the non-etching side of the original high-alumina-silicate glass mobile phone back shell with anti-etching ink silk screen printing;

[0023] (3) Clean the side of the original high-alumina silicon glass mobile phone back shell that needs to be...

Embodiment 2

[0026] A manufacturing process of square flash point effect of high alumina silicate glass, comprising the following steps:

[0027] (2) Configure high-alumina-silicate glass square flash point effect etching solution, stir evenly until the etching solution is in a uniform supersaturated solution state, and place the etching solution in the etching sand shower device;

[0028] The high-alumina silica glass square flash point effect etching solution is composed of the following raw materials in mass fraction: 30% NH 4 HF 2 , 8% KHF 2 , 10% NH 4 F. 25% HNO 3 , 12% H 2 SO 4 , 6% HCl, 8% MgSiF 6 , 10% BaSO 4 , 6% NaNO 3 , 0.8% K 2 SO 4 , 1.5% CuCl 2 , 1.8% CaCl 2 , 8% starch, 3% maltose, 25% H 2 O.

[0029] (2) Cover and protect the non-etching side of the original high-alumina-silicate glass mobile phone back shell with anti-etching ink silk screen printing;

[0030] (3) Clean the side of the original high-alumina silicon glass mobile phone back shell that needs to...

Embodiment 3

[0033] A manufacturing process of square flash point effect of high alumina silicate glass, comprising the following steps:

[0034] (3) Configure high-alumina-silicate glass square-shaped etching solution with flash point effect, stir evenly until the etching solution is in a uniform supersaturated solution state, and place the etching solution in the etching sand shower device;

[0035] The high-alumina silica glass square flash point effect etching solution is composed of the following raw materials in mass fraction: 24% NH 4 HF 2 , 5.5% KHF 2 , 7.5% NH 4 F. 20% HNO 3 , 10% H 2 SO 4 , 4.5% HCl, 6.5% MgSiF 6 , 8% BaSO 4 , 4% NaNO 3 , 0.65% K 2 SO 4 , 1.15% CuCl 2 , 1.5% CaCl 2 , 5.5% starch, 2% maltose, 20% H 2 O.

[0036](2) Cover and protect the non-etching side of the original high-alumina-silicate glass mobile phone back shell with anti-etching ink silk screen printing;

[0037] (3) Clean the side of the original high-alumina silicon glass mobile phone bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com