A kind of FPC product processing method

A technology of products and connectors, applied in the direction of coating non-metallic protective layer, laminated printed circuit boards, flexible printed circuit boards, etc., can solve the problems of long production cycle, affecting product reliability, high cost, etc., and reduce production The effect of manufacturing cost, avoiding the tinning phenomenon, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

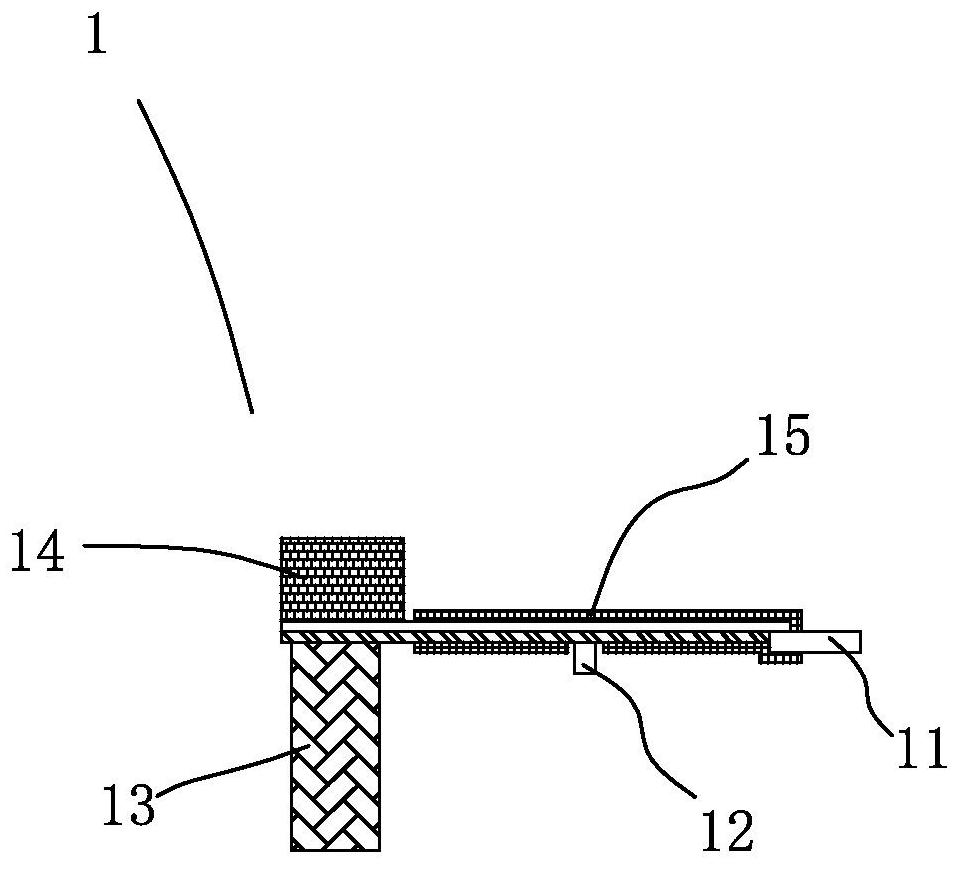

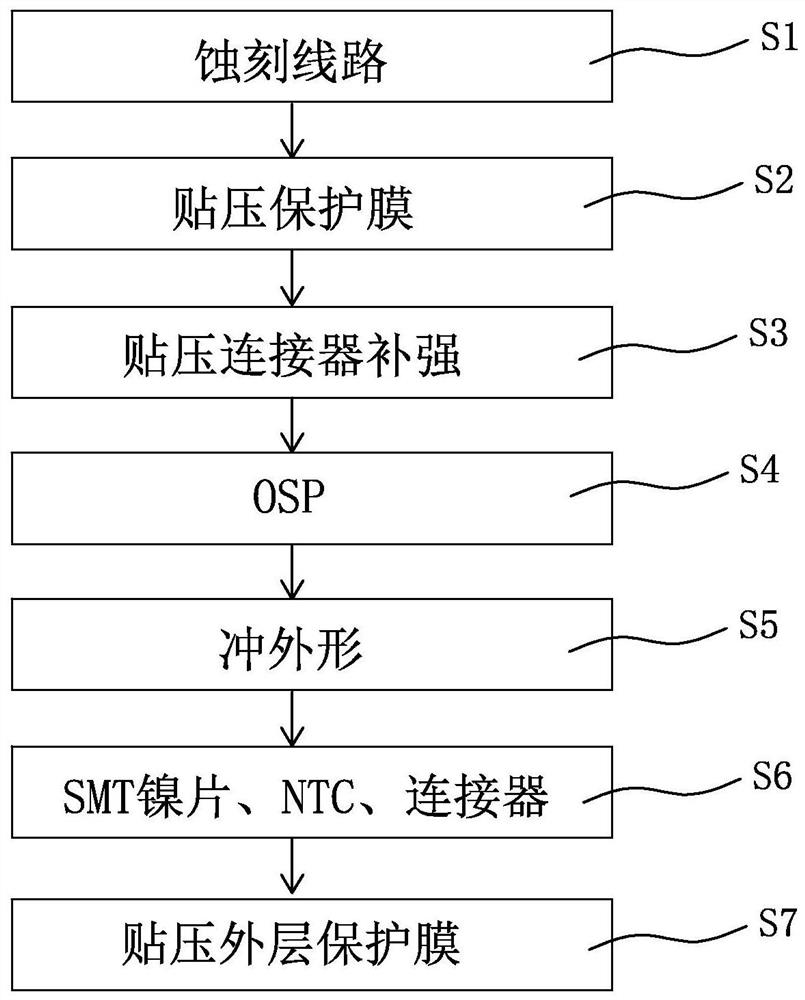

[0035] refer to Figure 1-8 , describing a method for processing figure 1 The FPC product 1 method shown. The method includes the following steps:

[0036] S1, etching circuit;

[0037] S2, paste the protective film;

[0038] S3. Reinforcing the pressure connector;

[0039] S4, OSP;

[0040] S5, Chong shape;

[0041] S6, SMT nickel sheet, NTC thermistor and connector;

[0042] And S7, paste and press the outer protective film. Wherein, S1 to S6 all adopt the existing technology, which will not be described here again. The specific process of S7 is as follows:

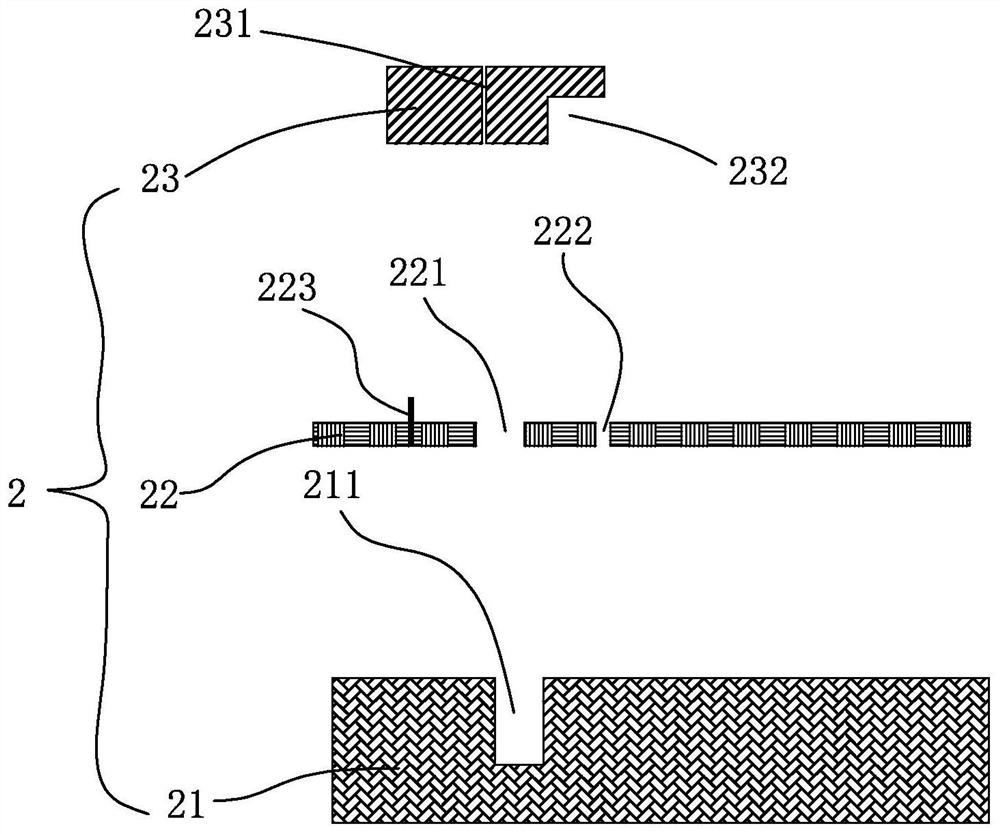

[0043] Provide a lamination fixture 2, such as image 3 with 4a As shown in -4c, the lamination fixture 2 includes a base plate 21, an intermediate elastic filling layer 22 and a cover plate 23. The base plate 21 is preferably an aluminum plate or steel plate with a thickness of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com