Method for preventing connected tin forming in wave soldering

A technology of soldering tin and wave soldering, which is applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of decreased solder fluidity, aggravated wave soldering joint tin generation, accelerated solder oxidation, etc. The effect of defect elimination and avoiding the formation of solder joint phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

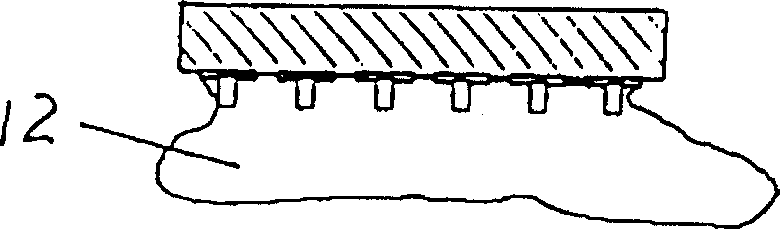

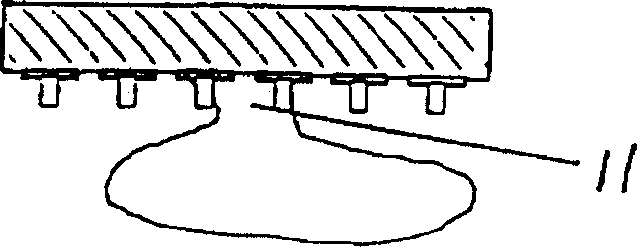

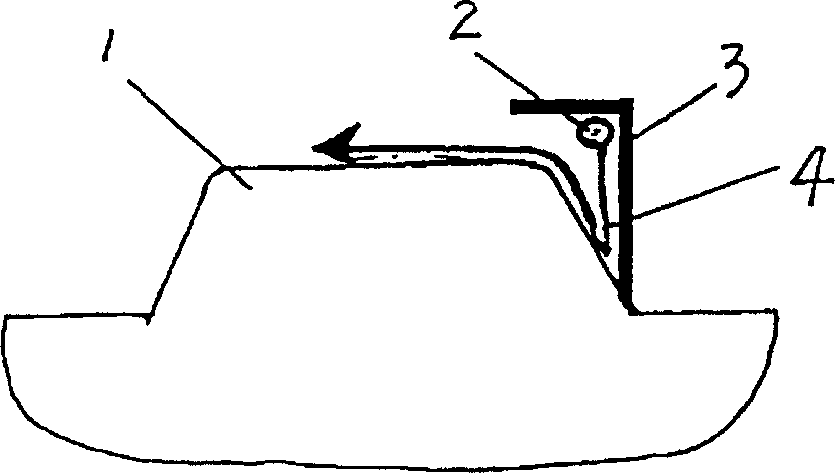

[0015] Before explaining the present invention, first describe the mechanism of connecting tin defects. We know that all wave soldering joints are not formed in tin waves even with tin. The amount of tin connection of the solder joint depends on the design of the circuit board, the activity of the flux when leaving the de-soldering point, and other factors. When the circuit board is separated from the tin wave, the amount of solder in the corresponding solder joint should have reached a certain saturation through capillary action. Only in this way can the solder bridge between adjacent solder joints be broken. Factors such as board design, solder mask type, and process conditions all ultimately determine the outcome of these force balances. Lian tin is usually in a critical steady state. When the solder joint leaves the tin wave, it is still in a capillary state. Usually, the central part of the deformation of the circuit board is the latest to leave the de-tinning point, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com