Pyroelectric composite positive electrode material and preparation method and application thereof

A technology of composite positive electrode material and positive electrode material, applied in the field of pyroelectric composite positive electrode material and its preparation, can solve the problem of slow ion migration rate at the interface between positive electrode matrix material and coating layer, difficult to overcome the problem of structural phase transition, and easy doping elements. generation and other problems, to achieve the effect of low material cost, prevention of heat accumulation, and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

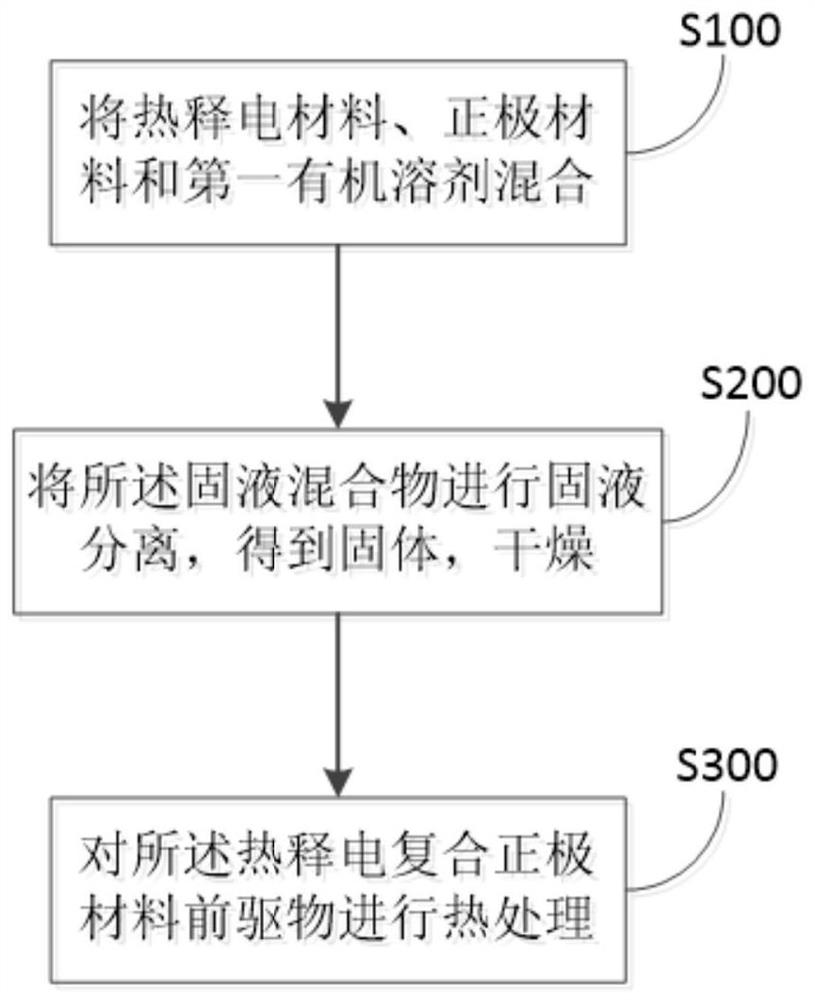

[0046] According to the method for preparing the pyroelectric composite positive electrode material in the embodiment of the present invention, the pyroelectric material and the positive electrode material are mixed evenly in an organic solvent, the small particle pyroelectric material will adhere to the surface of the large particle positive electrode material, and the wet after adding the solvent The method of mixing will be more uniform than the dry method, and the solvent can play a role in dispersion. After drying, the pyroelectric composite positive electrode material precursor is obtained, and then the pyroelectric composite positive electrode material precursor is subjected to heat treatment to obtain the pyroelectric composite positive electrode material. When the lithium-ion battery is charged and discharged, due to the existence of internal resistance to generate heat, the temperature of the entire battery rises, and the pyroelectric material mixed in the pyroelectri...

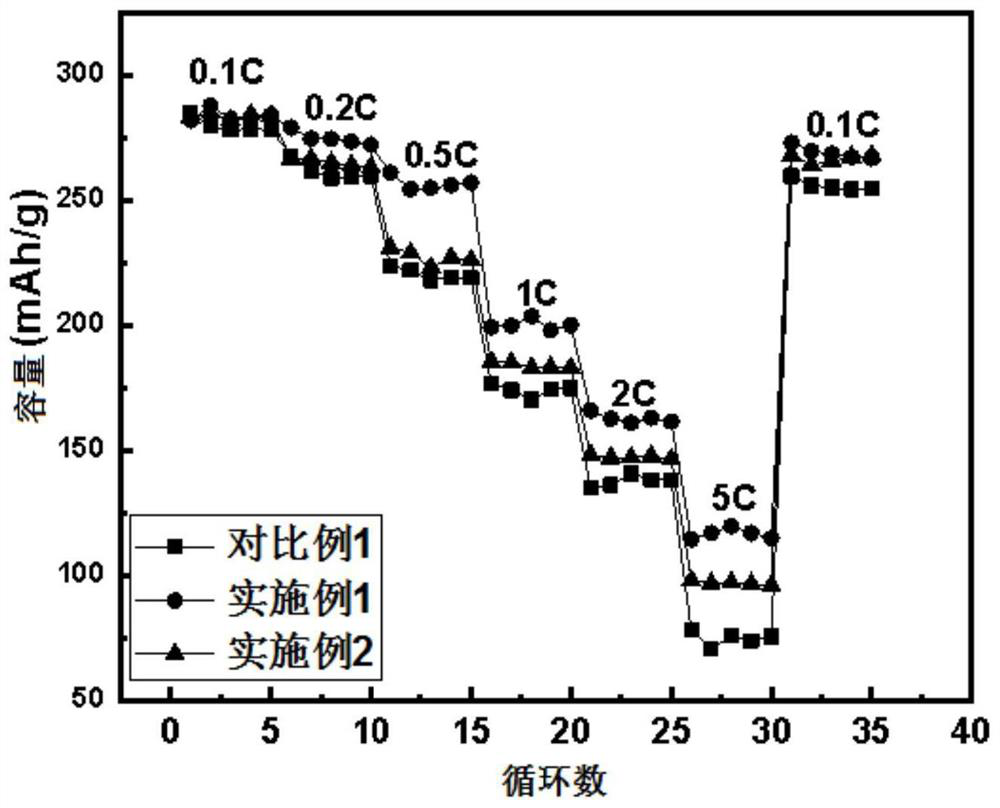

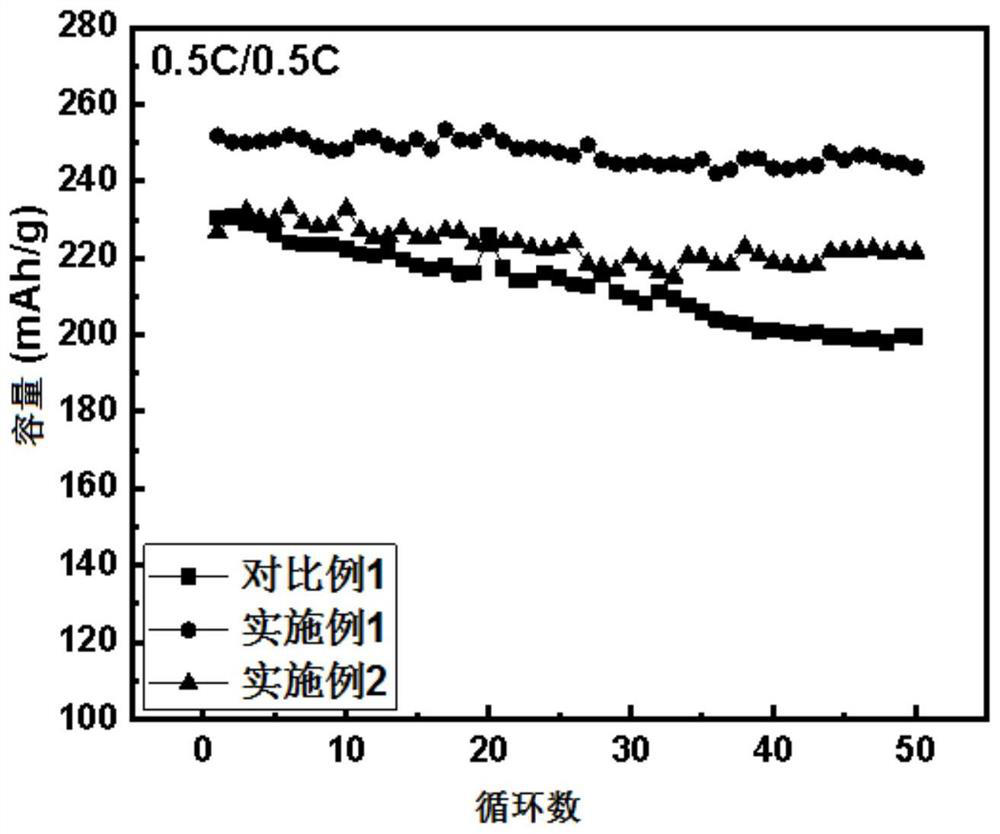

Embodiment 1

[0058] A preparation method of a lead germanate positive electrode composite pole piece:

[0059] (1) Dispersing lead germanate in ethylene glycol and wet ball milling, the ball milling time is 12h, and the particle size is 500nm;

[0060] (2) Continue to add a certain amount of lithium-rich manganese-based positive electrode materials in (1), and continue to add ethylene glycol, and continue to stir vigorously after ultrasonication for 10 minutes. The stirring time is 3 hours. The mass ratio of lithium-rich manganese-based to lead germanate is 100:1.5;

[0061] (3) Filtrating the suspension in (2), and placing the obtained filter residue in an oven to bake at 100° C. to obtain a lead germanate composite cathode material precursor;

[0062] (4) heat-treating the precursor obtained in (3) at 550° C. for 6 hours in a resistance furnace to obtain a lead germanate composite positive electrode material;

[0063] (5) Homogenize the composite positive electrode material in (4) with...

Embodiment 2

[0071] A kind of preparation of lead zirconate titanate positive electrode composite pole piece:

[0072] (1) Dispersing lead zirconate titanate in ethanol and wet ball milling, the ball milling time is 12h, and the particle size is 500nm;

[0073] (2) Continue to add a certain amount of nickel-cobalt lithium manganate positive electrode material in (1), and continue to add ethanol, continue to stir vigorously after ultrasonication for 10 minutes, and the stirring time is 3 hours. The mass of nickel-cobalt lithium manganate and lead zirconate titanate The ratio is 100:1;

[0074] (3) Filtrating the suspension in (2), and placing the obtained filter residue in an oven to bake at 100° C. to obtain a lead zirconate titanate composite cathode material precursor;

[0075] (4) heat-treating the precursor obtained in (3) at 650° C. for 6 hours in a resistance furnace to obtain a lead zirconate titanate composite positive electrode material;

[0076] (5) Homogenize the composite pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com