A platinum-based catalyst highly dispersed in carrier silica and its preparation method and application

A catalyst and highly dispersed technology, applied in the direction of carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of easy aggregation and growth, carbon deposition selectivity, etc., to achieve Not easy to agglomerate, improve the effect of easy sintering and increase conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

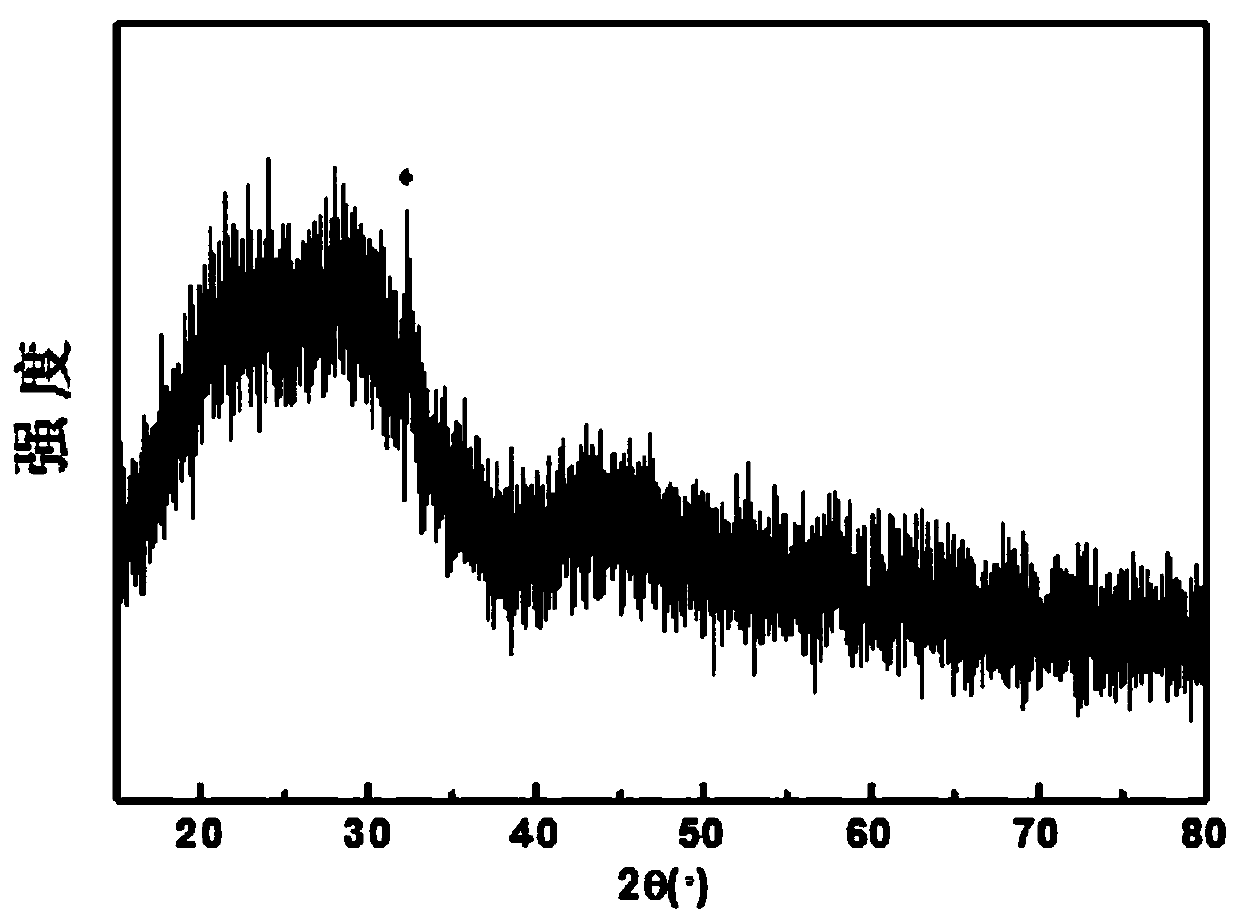

Image

Examples

Embodiment 1

[0029] (1) Take SiO 2 The white powder was placed in a 200mL crucible and placed in a muffle furnace. Roast at 700°C for 5h at a heating rate of 5°C / min. Take 2.1g SiO 2 In a 25mL small beaker.

[0030] (2) Take 1.5919g lanthanum nitrate hexahydrate, 0.8564g ferric nitrate nonahydrate, 0.4462g nickel nitrate hexahydrate, 1.2mL1.93×10 -2 mol / L chloroplatinic acid solution in a 25mL small beaker, add 7.2mL deionized water to dissolve.

[0031] (3) Add 1.6951g of anhydrous citric acid and 0.1mL of ethylene glycol into the above solution, stir to dissolve and mix well.

[0032] (4) Drop the solution obtained in (3) into the SiO in (1) 2On the carrier, stand at room temperature and fully impregnate for 24 hours to obtain a gel-like solid.

[0033] (5) Dry the above-mentioned gelatinous solid at 80°C for 6h, and at 120°C for 12h, and bake the dried product in a muffle furnace at 350°C for 2h, and at 700°C for 5h to obtain LaFe 1-x-y Ni x Pt y o 3 / SiO 2 (x=0.417, y=0.006)...

Embodiment 2

[0045] The method of Example 1 was used for the reaction, and the only difference was that the mass percentage of Pt in the total mass of the catalyst was 0.3%.

Embodiment 3

[0047] The method of Example 1 was used for the reaction, the only difference being that the mass percentage of Pt accounting for the total mass of the catalyst was 0.15%, and the mass percentage of NiO accounting for the total mass of the catalyst was respectively 0%.

[0048] Regarding the results and data of the above examples, the activity data of 280 minutes after the reaction were used for comparison to investigate the influence of different parameters on the reaction performance of the catalyst.

[0049] See Table 2 for the influence of Pt mass percentage content on catalyst reactivity. Reaction condition is with embodiment 1,2.

[0050] Table 2 Effect of Pt mass percentage content on catalyst reactivity and propylene selectivity

[0051] Pt mass percentage (%) Isobutane conversion rate (%) Isobutene selectivity (%) 0.15 19.84839224 91.58501193 0.3 35.28894992 92.1994382

[0052] As can be seen from the results in the table, after increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com